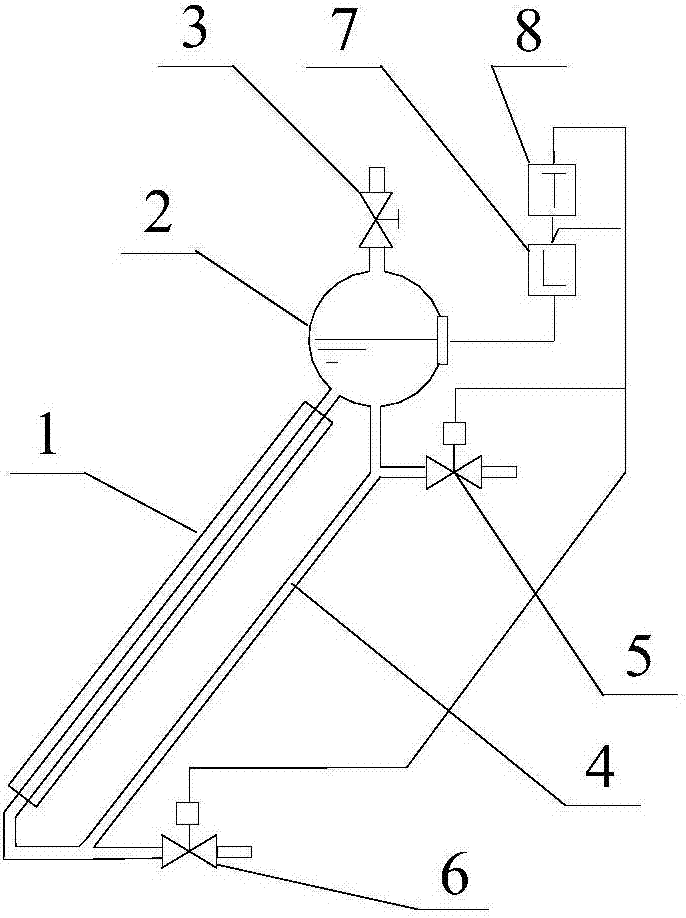

Hygroscopic solution regeneration system

A solution regeneration and solution technology, applied in the direction of evaporator regulation/control, forced circulation evaporator, evaporation, etc., can solve problems such as full utilization of unfavorable heat energy, increase of intermediate medium heat exchange links, and reduction of heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Based on the above moisture absorption solution regeneration system, a lithium bromide solution with a regeneration capacity of 12kg / h is designed as the moisture absorption solution. In the process of using 15 vacuum heat collectors to increase the concentration of the lithium bromide solution from 50% to 60%, the temperature of the lithium bromide solution is the highest It can reach 126°C.

Embodiment 2

[0043] Based on the above moisture absorption solution regeneration system, a lithium bromide solution with a regeneration capacity of 25kg / h is designed as the moisture absorption solution. In the process of using 30 vacuum heat collectors to increase the concentration of the lithium bromide solution from 50% to 60%, the temperature of the lithium bromide solution is the highest It can reach 135°C, the thermal efficiency of the system is about 57%, and under the condition of sufficient light, the renewable lithium bromide solution is about 150kg-200kg throughout the day.

Embodiment 3

[0045] Based on the above moisture absorption solution regeneration system, a lithium chloride solution with a regeneration capacity of 50kg / h is designed as the moisture absorption solution. In the process of using 60 vacuum heat collectors to increase the concentration of the lithium chloride solution from 50% to 60%, chlorine The temperature of the lithium chloride solution can reach a maximum of 132°C, and the thermal efficiency of the system is about 53%. In the case of sufficient light, the renewable lithium chloride solution is about 300kg-390kg throughout the day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com