Treatment process of UV oil paint spraying exhaust gas

A waste gas treatment and paint technology, applied in the direction of gas treatment, climate change adaptation, climate sustainability, etc., can solve the problems of difficult maintenance of waste gas treatment facilities, failure to solve the problem of paint mist, and the failure of VOC treatment facilities to operate normally, so as to achieve the goal of workers Low labor intensity, reduced manual intervention, and simple manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

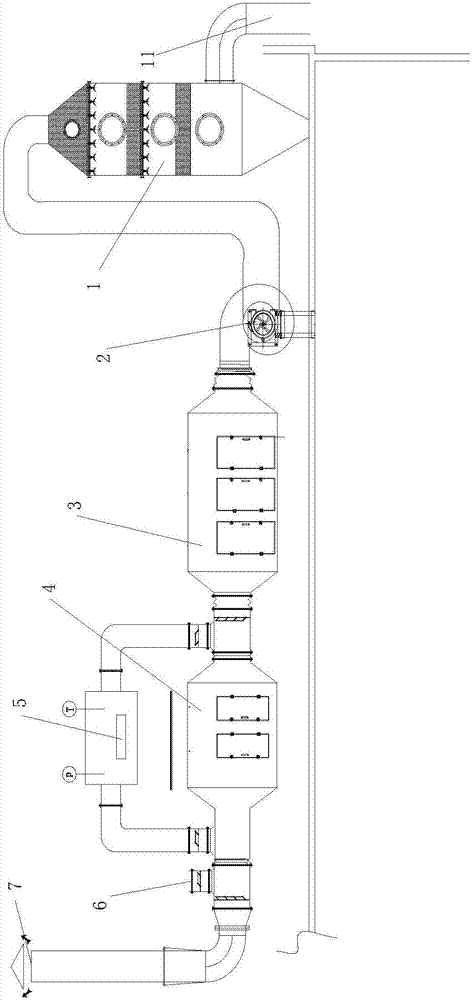

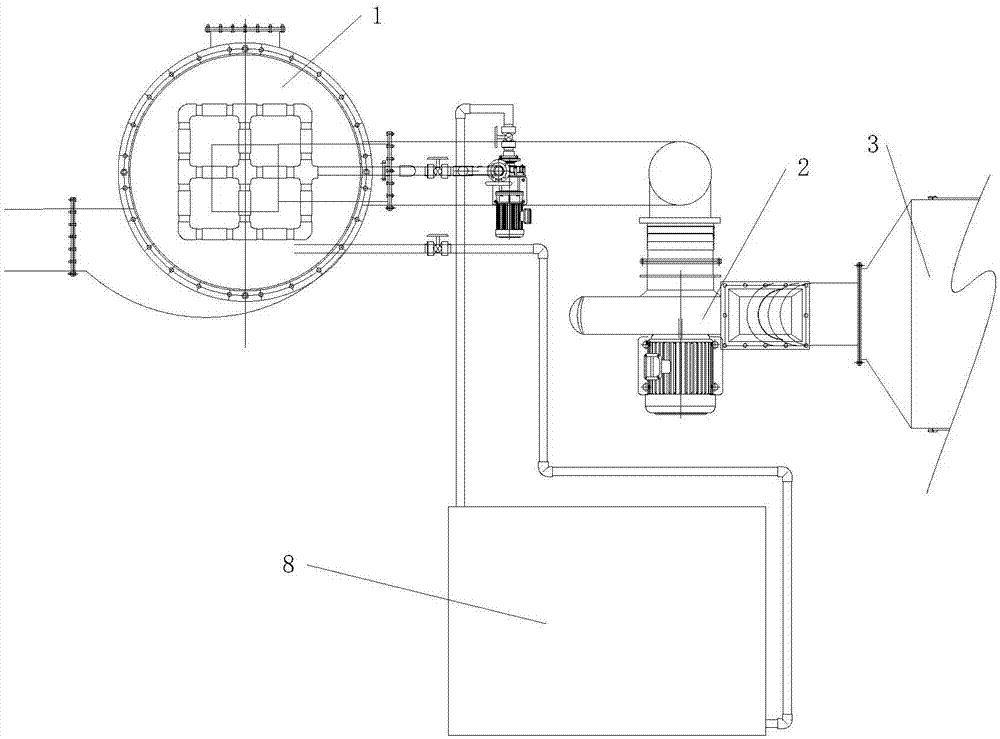

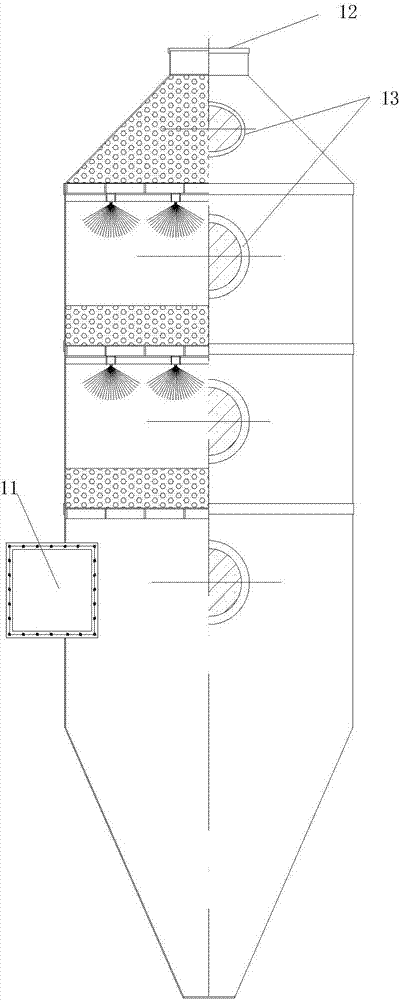

[0034] see as figure 1 -- Figure 9 As shown, the specific embodiment comprises a cyclone centrifugal spray tower 1, a centrifugal fan 2, a demister filter cabinet 3, an activated carbon adsorption cabinet 4, a catalytic combustion device 5, a sampling platform 6, and an outlet 7; the cyclone centrifugal spray tower 1 is connected with the circulating water tank 8; one end of the cyclone centrifugal spray tower 1 is provided with an air inlet 11; the top of the cyclone centrifugal spray tower 1 is connected with the centrifugal fan 2; One end of the mist filter cabinet 3 cooperates with each other; the other end of the demist filter cabinet 3 cooperates with the activated carbon adsorption cabinet 4; the outlet of the activated carbon adsorption cabinet 4 is connected with the sampling platform 6; the two ends of the catalytic combustion device 5 are respectively The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com