A three-dimensional nanorod al 2 o 3 @Molecular sieve shell-core composite material and its preparation method

A nano-molecular sieve and three-dimensional nano-technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, silicon compounds, etc., can solve the problems of increasing catalyst transmission diffusivity, catalyst carbon deposition deactivation, low reaction conversion rate, etc., to achieve load improvement Sexual effect and stability, simple preparation method, and the effect of increasing the mesopore specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

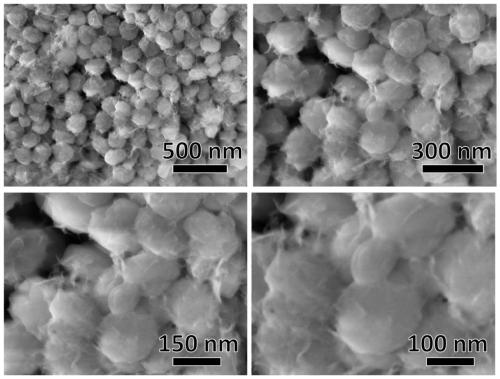

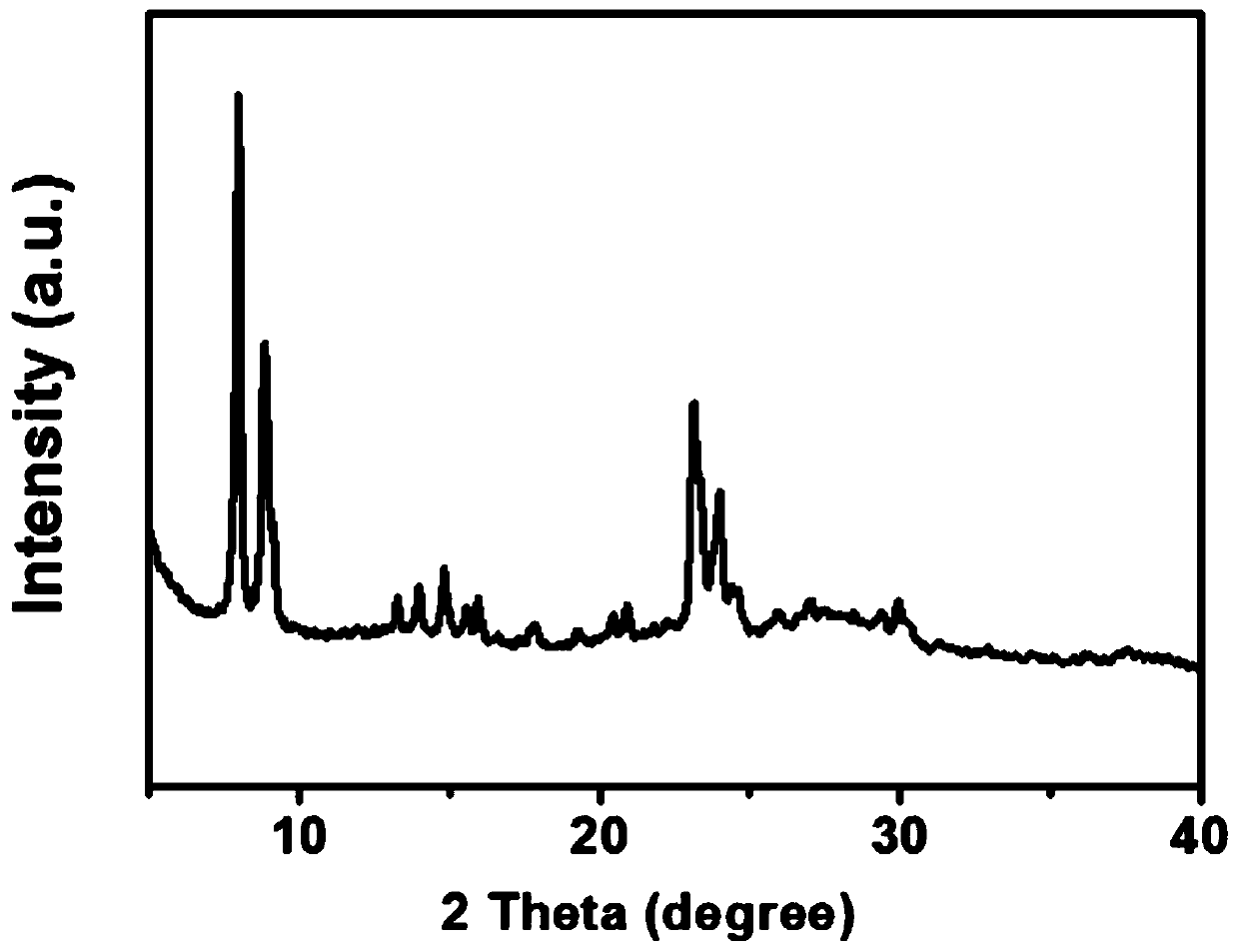

[0035] A three-dimensional nanorod Al 2 o 3 @Molecular sieve shell-core composite material, its preparation method includes the following steps:

[0036] 1) Synthesis of microporous nano-molecular sieves: 5.7g TPAOH (40wt%) and 10g TEOS were added to 16g deionized water, stirred for 3h, and mixed uniformly to obtain a clear solution I, which was poured into a reaction kettle and crystallized at 100°C. After 24 hours, remove the sample, wash it, dry it, and place it in a muffle furnace at 550°C for 7 hours to obtain a microporous nanomolecular sieve material;

[0037] 2) Add 0.25 g of the obtained microporous nano-molecular sieve material into 40 mL of isopropanol, and disperse uniformly by ultrasonication for 3 hours under sealed conditions to obtain a mixed liquid II;

[0038] 3) Add 1 g of aluminum sec-butoxide to the mixed solution II, stir for 30 minutes, and mix well to obtain mixed solution III (a mixed solution of aluminum sec-butoxide / molecular sieve);

[0039] 4) S...

Embodiment 2

[0043] A three-dimensional nanorod Al 2 o 3 @Molecular sieve shell-core composite material, its preparation method includes the following steps:

[0044] 1) Synthesis of microporous nano-molecular sieves: 5.7g TPAOH (40wt%), 10g silica sol (30wt%) were added into 16g deionized water, stirred for 2h, mixed uniformly to obtain a clear solution I, this solution was poured into the reactor, Crystallize at 100°C for 24 hours, remove the sample, wash it, dry it, and bake it in a muffle furnace at 550°C for 6 hours to obtain a microporous nanomolecular sieve material;

[0045] 2) Add 0.2 g of the obtained microporous nano-molecular sieve material into 50 mL of isopropanol, and disperse uniformly by ultrasonication for 3 hours under sealed conditions to obtain a mixed liquid II;

[0046] 3) Add 1 g of aluminum sec-butoxide to the mixed solution II, stir for 30 minutes, and mix well to obtain mixed solution III (a mixed solution of aluminum sec-butoxide / molecular sieve);

[0047] 4)...

Embodiment 3

[0053] A three-dimensional nanorod Al 2 o 3 @Molecular sieve shell-core composite material, its preparation method includes the following steps:

[0054] 1) the synthesis of microporous nano-molecular sieve: with 5.5g TPAOH (40wt%), 3g white carbon black (industrial nano-SiO 2 ) into 15 g of deionized water, stirred for 4 hours, and mixed uniformly to obtain a clear solution I. Pour the solution into a reaction kettle, crystallize at 110°C for 20 hours, remove the sample, wash it, dry it, and bake it in a muffle furnace at 550°C 6h, to obtain microporous nano-molecular sieve material;

[0055] 2) Add 0.3 g of the obtained microporous nano-molecular sieve material into 50 mL of isopropanol, and disperse evenly by ultrasonication for 3 hours under sealed conditions to obtain a mixed liquid II;

[0056] 3) Add 1.2 g of aluminum sec-butoxide to the mixed solution II, stir for 25 minutes, and mix well to obtain mixed solution III (mixed solution of aluminum sec-butoxide / molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com