Active carbon supported palladium catalyst for hydrogenation de-chlorination and preparation method thereof

A technology of hydrogenation dechlorination and palladium catalyst, which is applied in chemical industry and environmental protection field, can solve the problems of insufficient catalyst activity, excessive consumption of palladium metal, complicated production process, etc., and achieve enhanced selective adsorption capacity, reduced toxicity, and increased specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

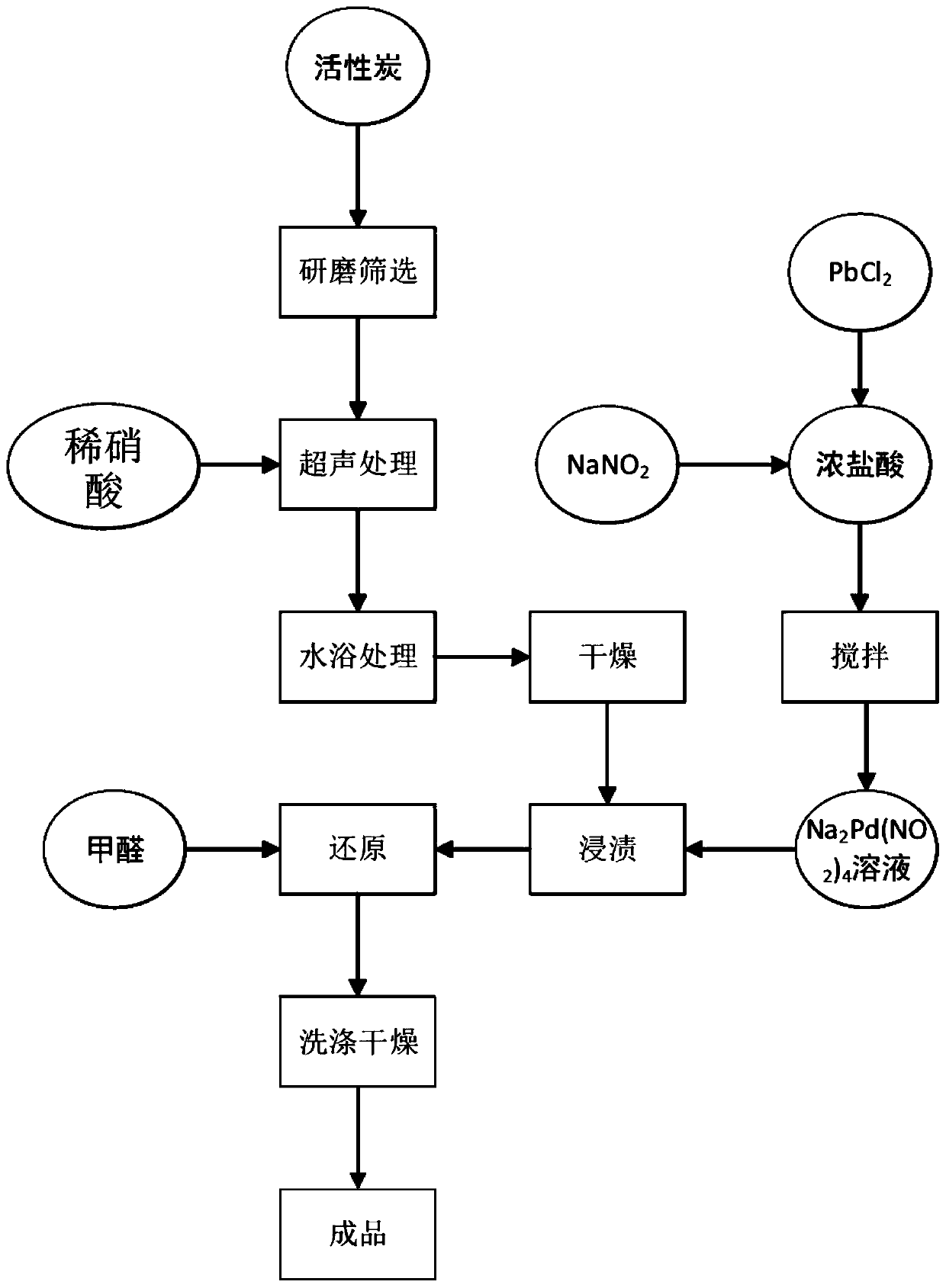

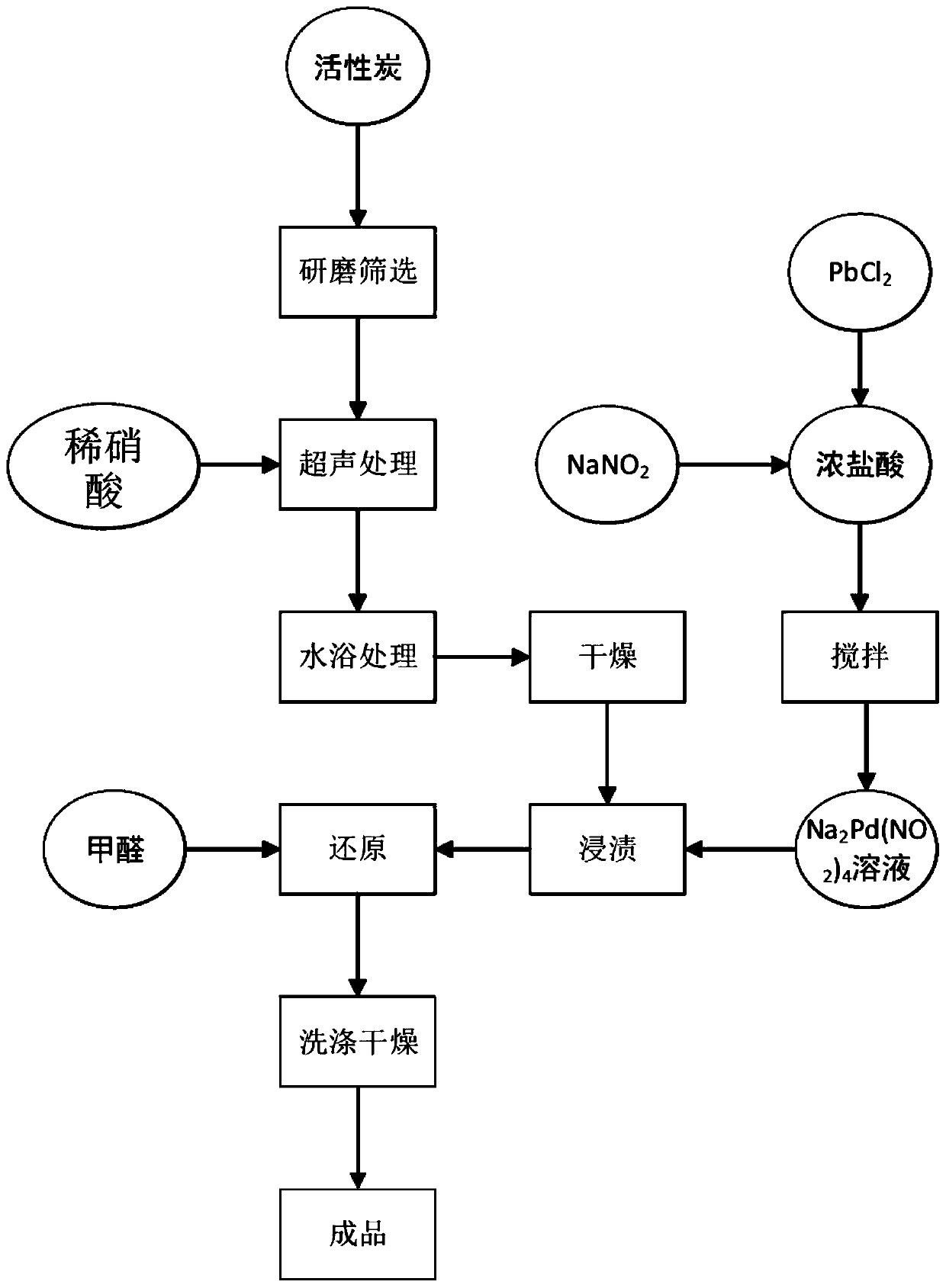

Method used

Image

Examples

Embodiment 1

[0037] (1) Activated carbon is ground, sieved, and the sieve hole of sieved is 80 orders, and the diameter of described powdery activated carbon particle is 0.18mm;

[0038] (2) 20g powdered activated carbon is put into the beaker, then add 20wt% dilute nitric acid solution 50mL (the mass volume ratio of described powdered activated carbon and dilute nitric acid solution is 2:5g / mL), stirring speed is 15rpm, stirs 5 Minutes, use an ultrasonic probe for 10 minutes, the ultrasonic frequency is 60kHz, then put it in a fume hood, treat it in a water bath at a constant temperature of 75°C for 18 hours, until no reddish-brown gas is released, wash the acid-washed activated carbon with distilled water until the last filtration The conductivity of the cleaning solution is up to 300us / cm, and it is placed in an oven, dried at 105°C for 4 hours, and then put into a reagent bag and sealed for storage;

[0039] (3) Weigh 10g PdCl 2 Dissolve in 20g of 36wt% concentrated hydrochloric acid ...

Embodiment 2

[0045] (1) activated carbon is ground, sieved, and the sieve hole of sieved is 120 orders, and the diameter of described powdery activated carbon particle is 0.125mm;

[0046] (2) 20g powdered activated carbon is put into the beaker, then add 15wt% dilute nitric acid solution 70ml (the mass volume ratio of powdered activated carbon and dilute nitric acid solution is 2:7g / mL), stirring speed is 10rpm, stirs 8 minutes, Use an ultrasonic probe for 15 minutes, the ultrasonic frequency is 80kHz, then put it in a fume hood, treat it in a water bath at a constant temperature of 80°C for 15 hours, until no reddish-brown gas is released, wash the acid-washed activated carbon with distilled water until the last filtered washing The conductivity of the solution is up to 300us / cm, and it is placed in an oven, dried at 110°C for 3 hours, and then put into a reagent bag for sealed storage;

[0047] (3) Weigh 10g PdCl 2 Dissolve in 25g of 37wt% concentrated hydrochloric acid solution, heat ...

Embodiment 3

[0053] The activated carbon is ground and sieved, and the sieve is 140 mesh, and the diameter of the powdered activated carbon particles is 0.1mm;

[0054] Put 20g of powdered activated carbon into a beaker, then add 100ml of 10wt% dilute nitric acid solution (the mass volume ratio of powdered activated carbon to dilute nitric acid solution is 2:10g / mL), the stirring rate is 5rpm, stir for 10 minutes, and use an ultrasonic probe to 20 minutes, the ultrasonic frequency is 100kHz, then put it into a fume hood, and treat it in a water bath at a constant temperature of 85°C for 20h, until no reddish-brown gas is released, and wash the acid-washed activated carbon with distilled water until the last filtered washing solution is neutral and place it in an oven, dry it at 120°C for 2 hours, then put it into a reagent bag and seal it for storage;

[0055] Weigh 10g PdCl 2 Dissolve in 30g of 38wt% concentrated hydrochloric acid solution, and heat slightly on the electric heating mantl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com