Process for producing strontium carbonate and barium carbonate without continuous carbonization of hydrogen sulfide gas holder

A technology of hydrogen sulfide and strontium carbonate, applied in the fields of strontium or barium compounds and calcium, which can solve the problems of backward technology, inability to realize continuous production and stability of old technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

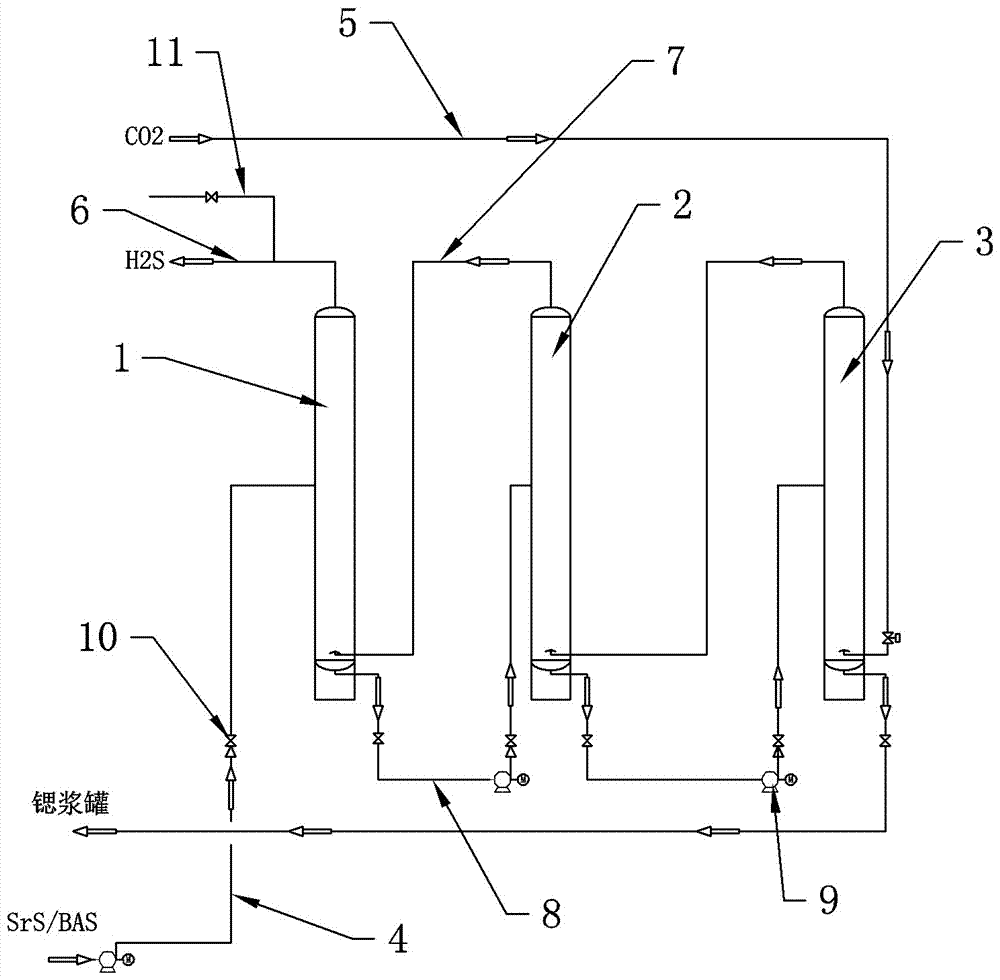

[0025] This embodiment is basically as attached figure 1 Shown: a continuous carbonization production system of strontium carbonate and barium carbonate without hydrogen sulfide cabinet, including liquid feed pipe 4, gas feed pipe 5, exhaust pipe 6, discharge pipe and a plurality of carbonization towers arranged in series (this Taking 3 carbonization towers as examples in the embodiment, they are respectively No. 1 carbonization tower 1, No. 2 carbonization tower 2 and No. 3 carbonization tower 3), and the liquid feed pipe 4 is communicated with the upper part of No. 1 carbonization tower 1; Between the carbonization towers, the bottom of the former carbonization tower is communicated with the upper part of the latter carbonization tower through the liquid pipeline 8, and the lower part of the former carbonization tower is communicated with the top of the latter carbonization tower through the gas pipeline 7; one end of the gas feed pipe 5 Be communicated with the bottom of No...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that: this embodiment is also provided with a controller, a magnetic flap level gauge and a flowmeter electrically connected to the controller respectively, and a magnetic flap is installed in each carbonization tower Liquid level gauge, liquid feed pipe 4, gas feed pipe 5, exhaust pipe 6, discharge pipe, liquid pipe 8 and gas pipe 7 are all provided with flow meters, and the liquid pump 9 is an electronically controlled pump, and the electric The control pump is electrically connected with the controller.

[0037] In the second, third or fifth step, the liquid level in each carbonization tower is detected by a magnetic flap liquid level gauge, and the liquid feed pipe 4, gas feed pipe 5, exhaust pipe 6, The flow rate in the discharge pipe, the liquid pipe 8 and the gas pipe 7, the signal detected by the magnetic flap liquid level meter is transmitted to the controller, and the controller controls the electronic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com