Quaternary ammonium salt modified diamine-terminated polydimethylsiloxane emulsion and preparation method and application thereof

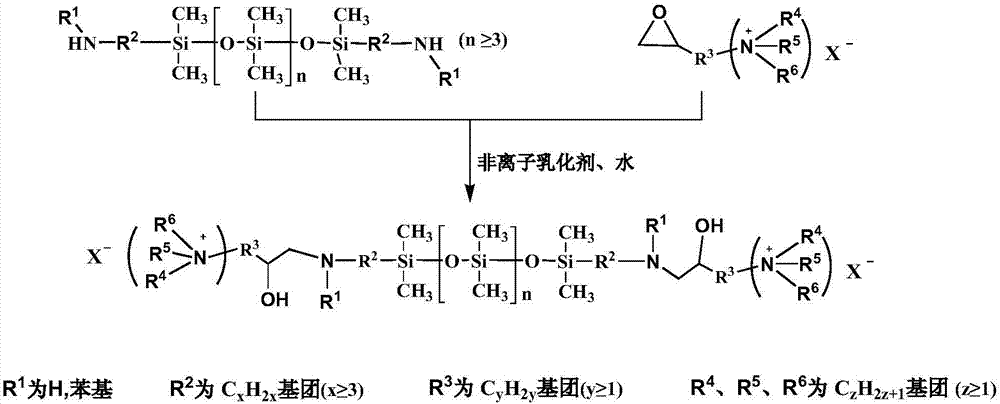

A technology of aminopolydimethylsiloxane and dimethylsiloxane, which is applied in the field of quaternary ammonium salt modified double-ended aminopolydimethylsiloxane emulsion and its preparation, and can solve the problem of difficult elution, Blockage of hair follicles, rigid hair and other problems, to achieve the effect of simple and easy preparation method, improved product performance, and strong anti-yellowing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of quaternary ammonium salt modified double-end amino polydimethylsiloxane emulsion comprises the following steps:

[0039] (1) Preparation of quaternary ammonium salt modified double-ended aminopolydimethylsiloxane:

[0040] 1.0g 2,3-epoxypropyltrimethylammonium chloride, 100.0g double-ended aminopropyl polydimethylsiloxane (6000cst / 25°C), 30.0g fatty alcohol polyoxyethylene ether O-8 . 5.0 g of deionized water was put into the reactor, stirred and dispersed evenly, and reacted for 10 hours at 60° C. to obtain a mixture of quaternary ammonium salt modified double-ended amino polydimethylsiloxane and emulsifier;

[0041](2) Emulsion preparation: the mixture of the quaternary ammonium salt modified double-ended amino polydimethylsiloxane obtained in step (1) and the emulsifier is transferred to an emulsifier, placed in a water bath at 60°C, and slowly dripped Add 300.0g deionized water and emulsify the material, add 0.3g citric acid and 0.3g 1,3-d...

Embodiment 2

[0044] The preparation method of quaternary ammonium salt modified double-end amino polydimethylsiloxane emulsion comprises the following steps:

[0045] (1) Preparation of quaternary ammonium salt modified double-ended aminopolydimethylsiloxane:

[0046] 1.1g 2,3-epoxypropyldimethylpropylammonium chloride, 100.0g double-ended aminopropyl polydimethylsiloxane (55000cst / 25℃), 30.0g nonylphenol polyoxyethylene ether TX-7, put 5.0g deionized water into the reactor, stir and disperse evenly, and react at 50°C for 10 hours to obtain a mixture of quaternary ammonium salt modified double-ended amino polydimethylsiloxane and emulsifier;

[0047] (2) Emulsion preparation: the mixture of the quaternary ammonium salt modified double-ended amino polydimethylsiloxane obtained in step (1) and the emulsifier is transferred to an emulsifier, placed in a water bath at 60°C, and slowly dripped Add 400.0g deionized water and emulsify the material, add 0.3g citric acid and 0.3g DMDMH after the e...

Embodiment 3

[0050] The preparation method of quaternary ammonium salt modified double-end amino polydimethylsiloxane emulsion comprises the following steps:

[0051] (1) Preparation of quaternary ammonium salt modified double-ended aminopolydimethylsiloxane:

[0052] 1.0g 2,3-epoxypropyltrimethylammonium bromide, 100.0g double-ended aminopropyl polydimethylsiloxane (5000cst / 25℃), 30.0g isomeric alcohol polyoxyethylene ether TO- 7. Put 5.0 g of deionized water into the reactor, stir and disperse evenly, and react at 50°C for 10 hours to obtain a mixture of quaternary ammonium salt modified double-ended amino polydimethylsiloxane and emulsifier;

[0053] (2) Emulsion preparation: the mixture of the quaternary ammonium salt modified double-ended amino polydimethylsiloxane obtained in step (1) and the emulsifier is transferred to an emulsifier, placed in a water bath at 60°C, and slowly dripped Add 320.0g deionized water and emulsify the material, add 0.3g citric acid and 0.3g DMDMH after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com