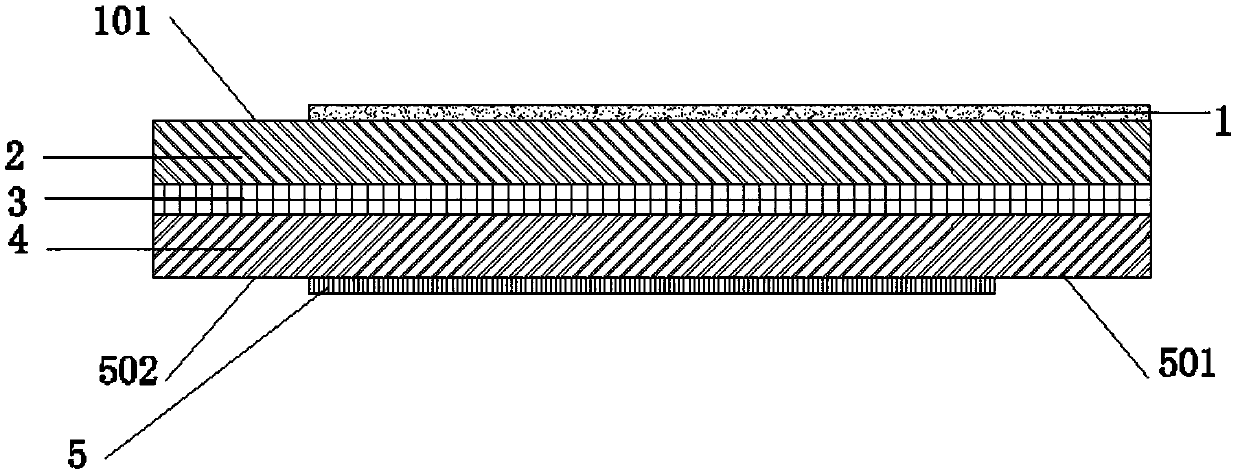

Flame-retardant modified asphalt, flame-retardant self-adhesive asphalt tile and preparation method thereof

A modified asphalt, flame-retardant technology, applied to other household appliances, roofs using tiles/slate tiles, applications, etc., can solve the problems of poor adhesion and poor flame retardancy of asphalt tiles, and achieve excellent adhesion performance, Effect of preventing molten dripping and strong gas barrier performance

- Summary

- Abstract

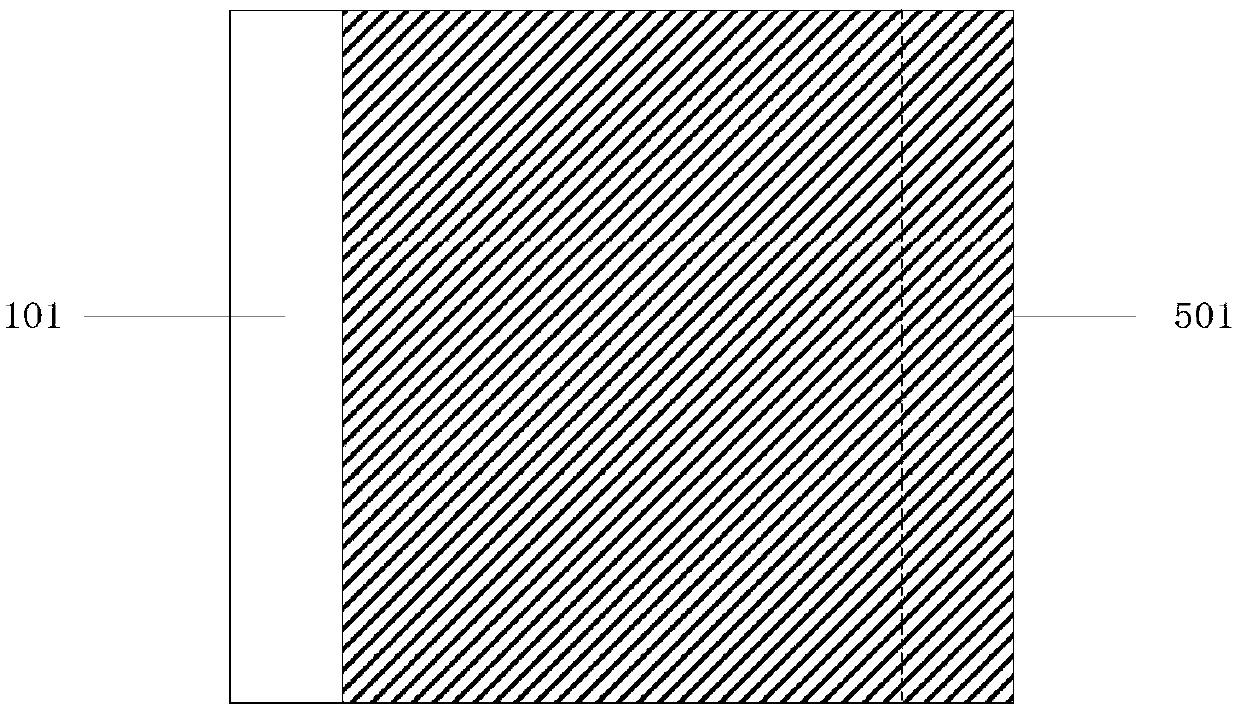

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

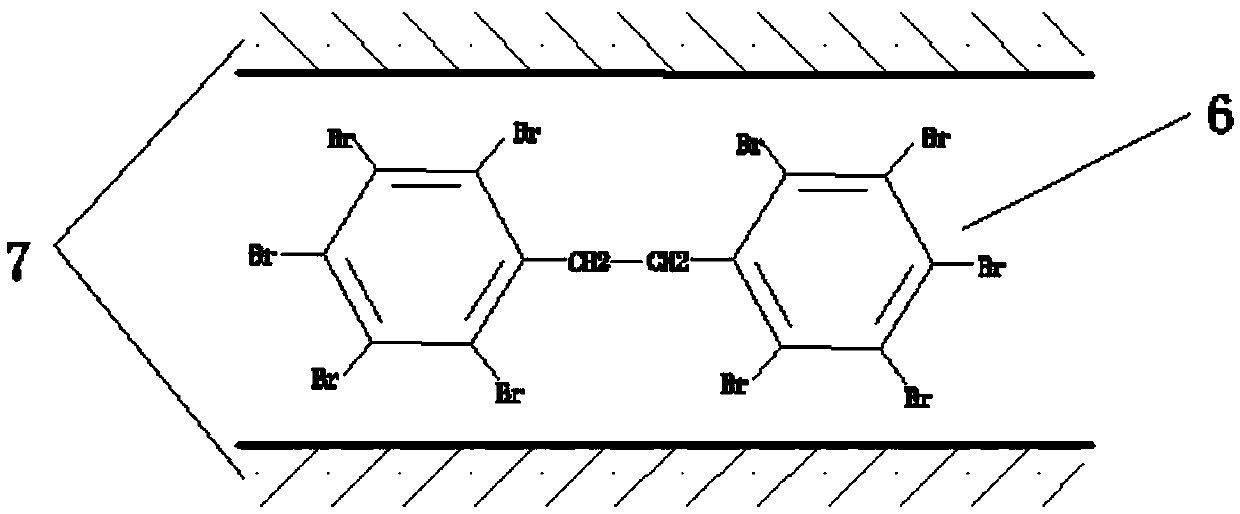

[0042] The preparation method of decabromodiphenylethane-organic montmorillonite is: prepare montmorillonite and decabromodiphenylethane with a mass ratio of 1:1; add montmorillonite (1000 mesh) to deionized water, Stir down for 30min, add NaCl crystals that account for 5% of the total mass of montmorillonite to form a mixed solution and continue to stir, control the temperature of the above mixed solution to rise to 70°C, adjust the Ph value of the above mixed solution to 7; Pour alkanes (with a particle size of 4 μm) as an intercalation agent into the mixed solution with a Ph value of 7 and continue to stir, control the rotation speed to 300r / min, control the temperature to rise to 80°C, stir for 1.5 hours and then let it stand for 30 minutes to obtain a flocculent precipitate. The product obtained by drying the above-mentioned flocculent precipitate in a drier at a temperature of 90° C. for 4 hours is the above-mentioned decabromodiphenylethane-organic montmorillonite.

Embodiment 2

[0044] The preparation method of decabromodiphenylethane-organic montmorillonite is: prepare montmorillonite and decabromodiphenylethane with a mass ratio of 1:2; add montmorillonite (2000 mesh) to deionized water, and Stir down for 30min, add NaCl crystals that account for 5% of the total mass of montmorillonite to form a mixed solution and continue to stir, control the temperature of the above mixed solution to rise to 70°C, adjust the Ph value of the above mixed solution to 7; Pour alkanes (with a particle size of 3 μm) as an intercalation agent into the mixed solution with a Ph value of 7 and continue to stir, control the rotation speed to 300r / min, control the temperature to rise to 85°C, stir for 1.5 hours and then let it stand for 30 minutes to obtain a flocculent precipitate. The product obtained by drying the above-mentioned flocculent precipitate in a drier at a temperature of 90° C. for 4 hours is the above-mentioned decabromodiphenylethane-organic montmorillonite. ...

Embodiment 3

[0046] The preparation method of decabromodiphenylethane-organic montmorillonite is: prepare montmorillonite and decabromodiphenylethane with a mass ratio of 1:3; add montmorillonite (3000 mesh) to deionized water, and Stir down for 30min, add NaCl crystals that account for 5% of the total mass of montmorillonite to form a mixed solution and continue to stir, control the temperature of the above mixed solution to rise to 70°C, adjust the Ph value of the above mixed solution to 7; Pour alkanes (with a particle size of 5 μm) as an intercalation agent into the mixed solution with a Ph value of 7 and continue to stir, control the rotation speed to 300r / min, control the temperature to rise to 85°C, stir for 2 hours and then let it stand for 30 minutes to obtain a flocculent precipitate. The product obtained by drying the above-mentioned flocculent precipitate in a drier at a temperature of 90° C. for 4 hours is the above-mentioned decabromodiphenylethane-organic montmorillonite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com