Antibacterial, antioxidant and pulping barrier coating resin for food packaging and preparation method of antibacterial, antioxidant and pulping barrier coating resin

A technology for food packaging and barrier coating, which is applied in coatings, paper coatings, textiles and papermaking, etc., can solve the problems of increasing the cost of coated paper, inability to take into account the performance, and not seen, and achieves the goal of being beneficial to food preservation and having good performance. Conducive to anti-corrosion and fresh-keeping, improving the effect of oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

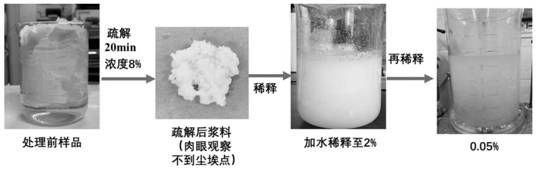

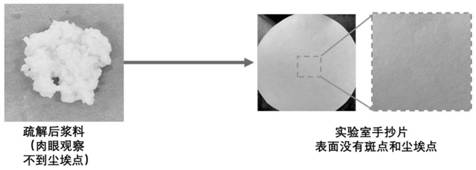

Method used

Image

Examples

Embodiment 1

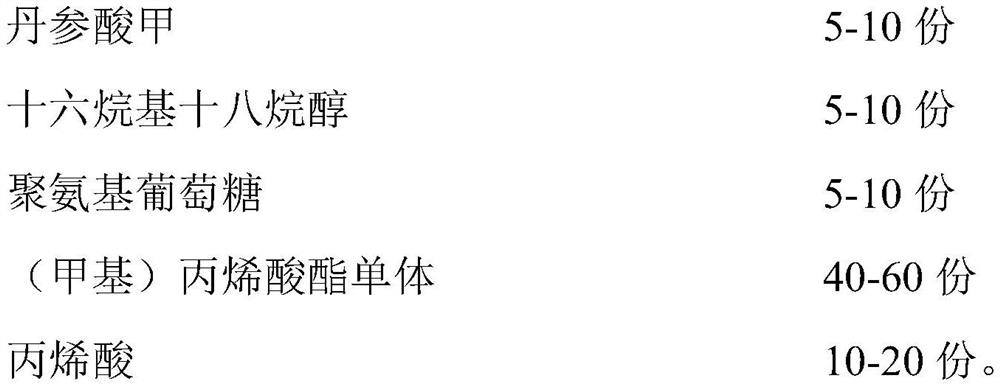

[0052] An antibacterial, anti-oxidation, and beating barrier coating resin for food packaging. The raw materials used in the synthesis process include:

[0053]

[0054] The preparation method of the antibacterial, anti-oxidation and beating barrier coating resin for food packaging comprises:

[0055] Step 1: Preparation of cetyl octadecyl salvianic acid modified acrylic acid crystals:

[0056] a. Add 8 parts of salvianic acid A to 12 parts of 95% concentrated sulfuric acid, stir until completely dissolved, then add 6 parts of cetyl stearyl alcohol for esterification reaction, control the reaction temperature at 30°C, and react for 2 hours , to obtain the reaction solution.

[0057] b. Pour the obtained reaction solution into rapidly stirred ice cubes to crystallize the obtained product and filter it.

[0058] c. Wash the filter cake with a mixed solution of ethanol ether (3:1) and saturated sodium carbonate, then remove ethanol and ether by evaporation, and finally dry i...

Embodiment 2

[0071] An antibacterial, anti-oxidation, and beating barrier coating resin for food packaging. The raw materials used in the synthesis process include:

[0072]

[0073] The preparation method of the antibacterial, anti-oxidation and beating barrier coating resin for food packaging comprises:

[0074] Step 1: Preparation of cetyl octadecyl salvianic acid modified acrylic acid crystals:

[0075] a. Add 5 parts of salvianic acid A to 8 parts of 98% concentrated sulfuric acid, stir until completely dissolved, then add 7.5 parts of cetyl stearyl alcohol for esterification reaction, control the reaction temperature at 35°C, and react for 2 hours , to obtain the reaction solution.

[0076] b. Pour the obtained reaction solution into rapidly stirred ice cubes to crystallize the obtained product and filter it.

[0077] c. Wash the filter cake with a mixed solution of ethanol ether (3:1) and saturated sodium carbonate, then remove ethanol and ether by evaporation, and finally dry ...

Embodiment 3

[0090] An antibacterial, anti-oxidation, and beating barrier coating resin for food packaging. The raw materials used in the synthesis process include:

[0091]

[0092] The preparation method of the antibacterial, anti-oxidation and beating barrier coating resin for food packaging comprises:

[0093] Step 1: Preparation of cetyl octadecyl salvianic acid modified acrylic acid crystals:

[0094] a. Add 10 parts of salvianic acid A to 15 parts of 98% concentrated sulfuric acid, stir until completely dissolved, then add 9 parts of cetyl stearyl alcohol for esterification reaction, control the reaction temperature at 35 °C, and react for 2.5 h, to obtain the reaction solution.

[0095] b. Pour the obtained reaction solution into rapidly stirred ice cubes to crystallize the obtained product and filter it.

[0096] c. Wash the filter cake with a mixed solution of ethanol ether (3:1) and saturated sodium carbonate, then remove ethanol and ether by evaporation, and finally dry it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com