A kind of anti-oxidation coating for color-coated board surface and preparation method thereof

An anti-oxidative coating and color-coated board technology, applied in the field of coatings, can solve problems such as cracking of color-coated boards, reduced service life, potential safety hazards, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

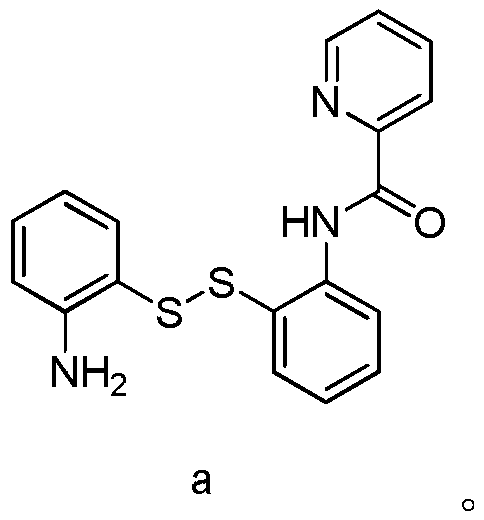

[0035] The synthesis method of arylamine curing agent is: add 1mol bis(2-aminophenyl) disulfide, 0.01mol 4-dimethylaminopyridine and 5ml solvent tetrahydrofuran into the reaction flask, stir at room temperature until the raw materials are completely dissolved, and then Add 1 mol of 2-pyridinecarbonyl chloride dropwise in an ice bath. After the dropwise addition, react at room temperature for 80 minutes, remove the solvent by rotary evaporation, and use column chromatography with dichloromethane:petroleum ether=2:5 as the chromatographic solution to obtain the formula a Structure of aromatic amine curing agent:

[0036]

[0037] Detected by GC-MS: aromatic amine curing agent a (C 18 h 15 N 3 OS 2 ) has a molecular weight of 352.962;

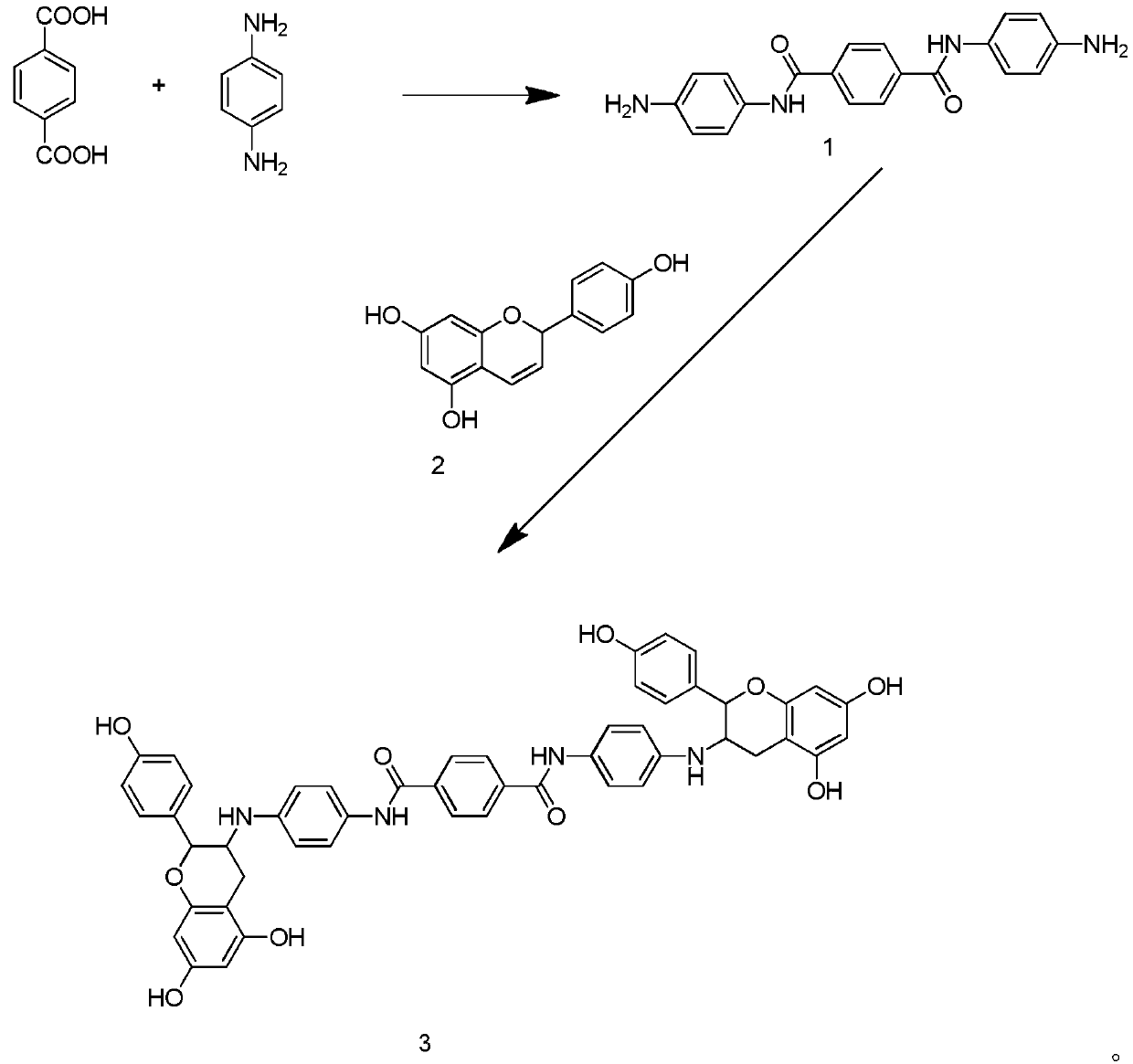

[0038] Antioxidant is obtained by addition of anthocyanidin 2 and terephthalic acid and p-phenylenediamine, and the molar ratio of described anthocyanidin, terephthalic acid and p-phenylenediamine is 2:2.5-3: 1; The synthesis method of ant...

Embodiment 2

[0042] No antioxidants added:

[0043] The weight of each raw material of anti-oxidation coating is: 60g of epoxy resin, 10g of urea melamine resin, 6g of polytetrafluoroethylene, 4g of diabase powder, 3g of porcelain powder, 1g of corundum, 4g of composite curing agent, 0.5g of curing accelerator, Triol 5.5g, dioxypropylene ethyl ether 6g;

[0044] A preparation method for an anti-oxidation coating on the surface of a color-coated plate, specifically comprising the following steps:

[0045] S1, dispersion grinding

[0046] Add epoxy resin, diabase powder, porcelain powder, carborundum and glycerol into a high-speed disperser for dispersion, and then pass through a ball mill for grinding through an 80-mesh sieve;

[0047] S2, melting and solidification

[0048]Add the sieved mixture into the screw extruder, then add urea melamine resin, polytetrafluoroethylene, composite curing agent and curing accelerator, the screw extruder host speed is 45Hz, the feeding speed is 25Hz, a...

Embodiment 3

[0050] No modification of epoxy resin and no addition of antioxidants:

[0051] The weight of each raw material of the anti-oxidation coating is: epoxy resin 70g, diabase powder 5g, porcelain powder 5g, corundum 2g, glycerin 10g, dioxypropylene ethyl ether 8g;

[0052] A preparation method for an anti-oxidation coating on the surface of a color-coated plate, specifically comprising the following steps:

[0053] S1, dispersion grinding

[0054] Add epoxy resin, diabase powder, porcelain powder, carborundum and glycerol into a high-speed disperser for dispersion, and then pass through a ball mill for grinding through an 80-mesh sieve;

[0055] S2, melting and solidification

[0056] Add the sieved mixture into the screw extruder, then add urea melamine resin, polytetrafluoroethylene, composite curing agent and curing accelerator, the main engine speed of the screw extruder is 40Hz, the feeding speed is 30Hz, extrude The temperature is 85°C in the first zone, and 160°C in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com