A visible/infrared compatible adaptive camouflage coating and its preparation method

An adaptive and coating technology, applied in the field of camouflage stealth materials, can solve the problems of difficult multi-spectral camouflage, incompatibility of visible light bands, etc., and achieve the effect of simple process, low cost, and widening application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

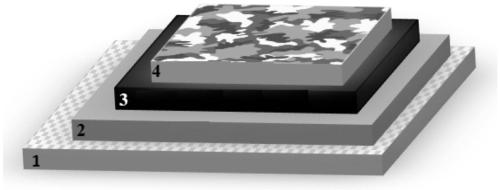

[0038] A visible / infrared compatible adaptive camouflage coating of the present invention is a layered structure, such as figure 1As shown, it includes a base layer 1 , a primer layer 2 , a thermochromic infrared emissivity layer 3 and a camouflage pattern layer 4 from inside to outside. Wherein, the base layer 1 is nylon fabric, yarn count: 70D; the base layer 2 is made of a fluorocarbon resin adhesive and a diluent (xylene and butyl acetate in a ratio of 4:1 by mass ratio) The primer paint prepared by mixing the obtained mixture) is obtained by scraping, and its thickness is 20-30 μm; the thermally variable infrared emissivity layer 3 is made of fluorocarbon resin binder, thinner, vanadium dioxide nano-powder The vanadium dioxide paint formulated with BYK dispersant (model DISPERBYK-162) is obtained by scraping, wherein the mass ratio of fluorocarbon resin binder and diluent is 1:2, fluorocarbon resin binder, The mass ratio of vanadium dioxide nanopowder and BYK dispersant ...

Embodiment 2

[0049] A visible / infrared compatible adaptive camouflage coating of the present invention is a layered structure, such as figure 1 As shown, it includes a base layer 1, a base layer 2, a thermochromic infrared emissivity layer 3 and a camouflage pattern layer 4 from the inside to the outside, wherein the base layer 1 is a PET film with a thickness of 2 μm; the base layer 2 is made of The primer paint made of fluorocarbon resin and diluent (a mixture of xylene and butyl acetate in a ratio of 4:1) with a ratio of 1:1 is obtained by scraping, and its thickness is 20-30 μm; The variable infrared emissivity layer 3 is obtained by scraping the vanadium dioxide coating prepared by fluorocarbon resin binder, diluent, vanadium dioxide nanopowder and BYK dispersant (model is DISPERBYK-162), wherein , the mass ratio of fluorocarbon resin binder and diluent is 1:4, the ratio of fluorocarbon resin binder, vanadium dioxide nanopowder and BYK dispersant (model DISPERBYK-162) is 160:20:1 , t...

Embodiment 3

[0059] A visible / infrared compatible adaptive camouflage coating of the present invention is a layered structure, such as figure 1 As shown, it includes a base layer 1, a base layer 2, a thermochromic infrared emissivity layer 3 and a camouflage pattern layer 4 from the inside to the outside, wherein the base layer 1 is a PE film with a thickness of 4 μm; the base layer 2 is made of fluorine The primer paint made of carbon resin and diluent (the mixture of xylene and butyl acetate at a volume ratio of 4:1) is obtained by scraping, and its thickness is 20-30 μm; the thermally variable infrared emissivity Layer 3 is obtained by scraping the vanadium dioxide coating prepared by fluorocarbon resin binder, diluent, vanadium dioxide nanopowder and BYK dispersant (model DISPERBYK-163), wherein the fluorocarbon resin adhesive The mass ratio of mixture and diluent is 1:2, and the mass ratio of fluorocarbon resin binder, vanadium dioxide nanopowder and BYK dispersant (model DISPERBYK-16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com