High-power brushless DC motor torque ripple control device and control method thereof

A brush DC motor and torque fluctuation technology, which is applied in the direction of torque ripple control, can solve the problems of high-power brushless DC motor torque fluctuation, etc., and achieve the effect of flexible control method, strong practicability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

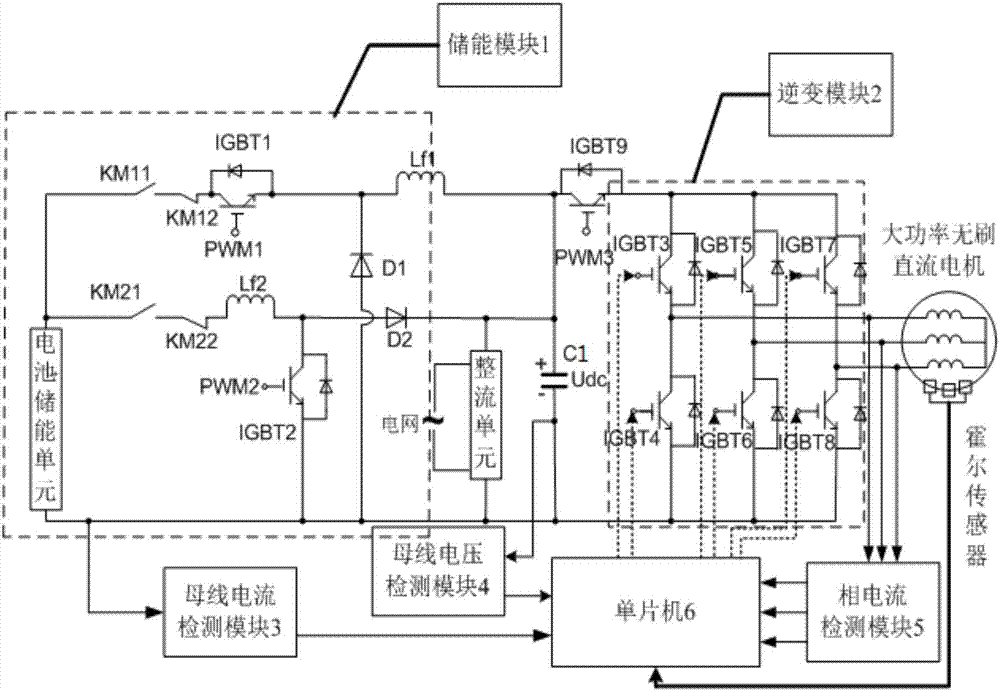

[0035] The present invention provides a high-power brushless DC motor torque fluctuation control device, such as figure 1 As shown, it includes an energy storage module 1 , an inverter module 2 , a bus current detection module 3 , a bus voltage detection module 4 , a phase current detection module 5 and a single chip microcomputer 6 .

[0036] The input end of the inverter module 2 is connected to the power supply, and the output end of the inverter module 2 is connected to the current input end of the DC motor.

[0037] An energy storage module 1, which includes a battery energy storage unit, a first branch and a second branch, the output positive pole of the battery energy storage unit is respectively connected to the first branch and the second branch, and the first branch is routed to The sequentially connected first normally open relay KM11, the first normally closed relay KM12 and the step-down chopper circuit are composed, and the second branch is composed of the sequen...

Embodiment 2

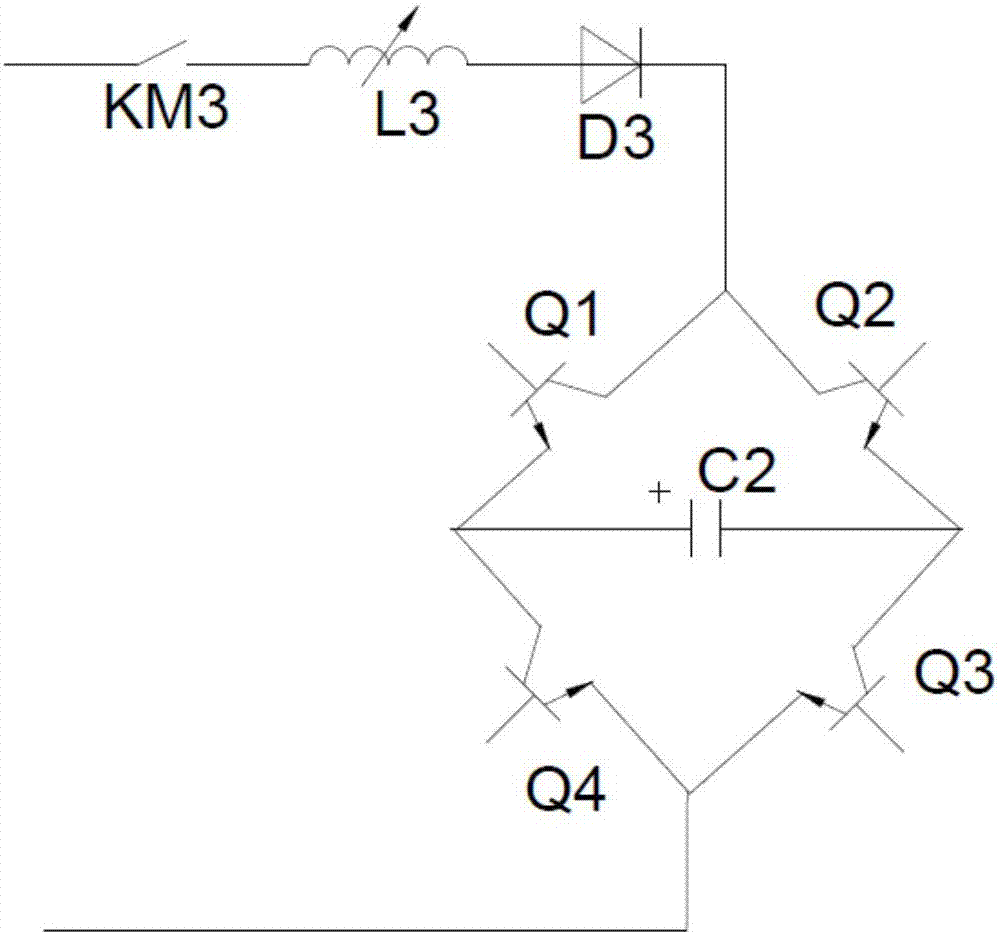

[0047] On the basis of Embodiment 1, a primary voltage stabilizing circuit is also connected to both ends of the terminal capacitor C1, such as figure 2 As shown, the secondary voltage stabilizing circuit includes a third normally open relay KM3, an adjustable inductance L3, a third diode D3, a double-arm bridge composed of four transistors Q1-Q4, and a double-arm bridge connected in sequence. The slow charging capacitor C2 between the arm bridges, the other end of the third normally open relay KM3 is connected to the positive end of the terminal capacitor C1, and the first end of the double arm bridge is connected to the third diode The cathode terminal of D3, the second terminal of the double-arm bridge is connected to the negative terminal of the terminal capacitor C1, and the control terminals of each triode are connected to the single-chip microcomputer 6 .

[0048] The secondary voltage stabilizing circuit in this embodiment has a simple structure and low cost. When the...

Embodiment 3

[0050] A control method for a high-power brushless DC motor torque fluctuation control device, comprising the following steps:

[0051] Step 1. When the system is turned on, the brushless DC motor is not started. The bus voltage detection module 4 detects the bus voltage between the primary terminal capacitors C1 in each algorithm cycle. After 100 cycles of detection, the single chip computer 6 calculates the average bus voltage U dcavg ;

[0052] Step 2: Start the brushless DC motor. During the non-commutation period of the brushless DC motor, the bus voltage detection module 4 detects the real-time bus voltage U' between the primary terminal capacitors C1 in each algorithm cycle dc , the bus current detection module also detects the bus current once in each algorithm cycle, and after 50 cycle detections, the single-chip microcomputer 6 calculates the average bus current I 0avg , and at the same time, in each algorithm cycle, the real-time bus voltage U' is judged by the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com