Coupling bionic resistance-reducing viscosity-reducing ploughshare

A ploughshare and drag reduction technology, applied in ploughs, agricultural machinery and implements, applications, etc., can solve the problems of reduced service life of ploughshares, insignificant deep loosening effect, and poor economy, and achieves reduced adhesion and reduced The effect of resistance, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

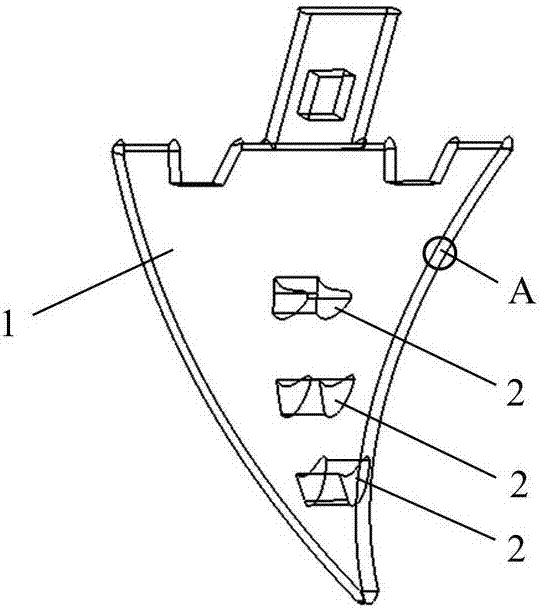

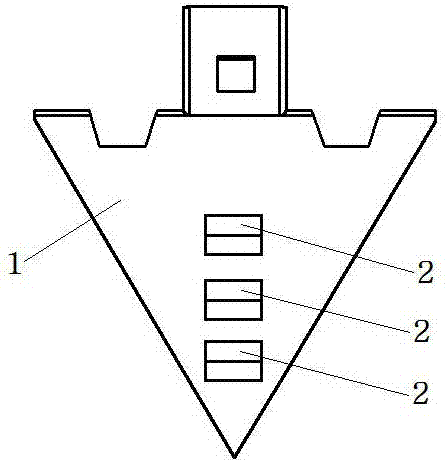

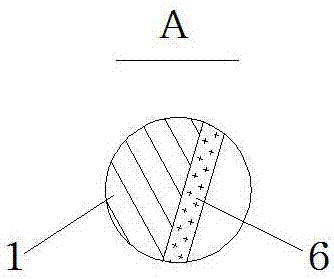

[0021] see Figure 1 to Figure 7 As shown, the present invention is composed of a plowshare main body 1 and a bionic claw toe 2, the surface of the plowshare is coated with a layer of polytetrafluoroethylene coating 6, and the cross-sectional profile of the bionic claw toe 2 is composed of three curves, wherein x is The abscissa, y is the ordinate:

[0022] The first curve 3 fits: y=0.09375x 2 -0.125x+3; where: 0≤x≤8;

[0023] The second curve 4 conforms to: y=0.125x 2 -x+8; where: 0≤x≤8;

[0024] The third curve 5 corresponds to: x=0; where: 3≤y≤8.

[0025] The thickness of the bionic claw toe 2 is 50 mm. The bionic claw toe 2 is distributed at equal intervals on the vertical center line of the concave surface of the plowshare body 1 at an interval of 50 mm. The material of the bionic claw toe 2 is cast steel. The bionic claw toe 2 and the plowshare The concave surface connection method of the main body 1 is welding.

[0026] The polytetrafluoroethylene coating 6 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com