Functional composite dietary fiber, preparation method and application

A compound dietary fiber and functional technology, applied in the field of feed, can solve the problems of not being able to meet the nutritional needs of pigs, the fiber cannot be fully separated, and cannot be used in the large intestine, so as to improve the survival rate of weaning, increase the number of live piglets, and increase the daily average The effect of feed intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The preparation method of the above-mentioned functional compound dietary fiber comprises weighing the compound dietary fiber, compound oil, compound lactic acid bacteria and carrier by parts by weight, and mixing them evenly to obtain the functional compound dietary fiber. The preparation method is simple and convenient, and the production efficiency is high.

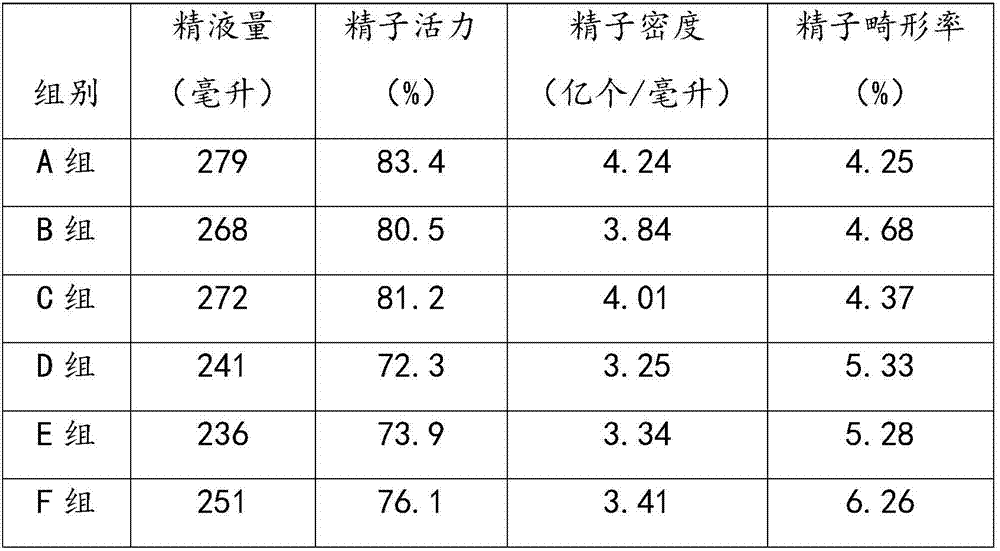

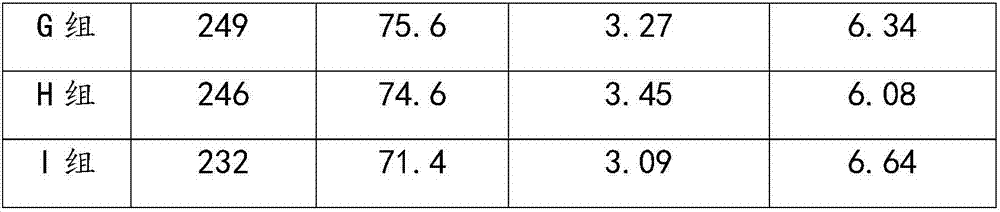

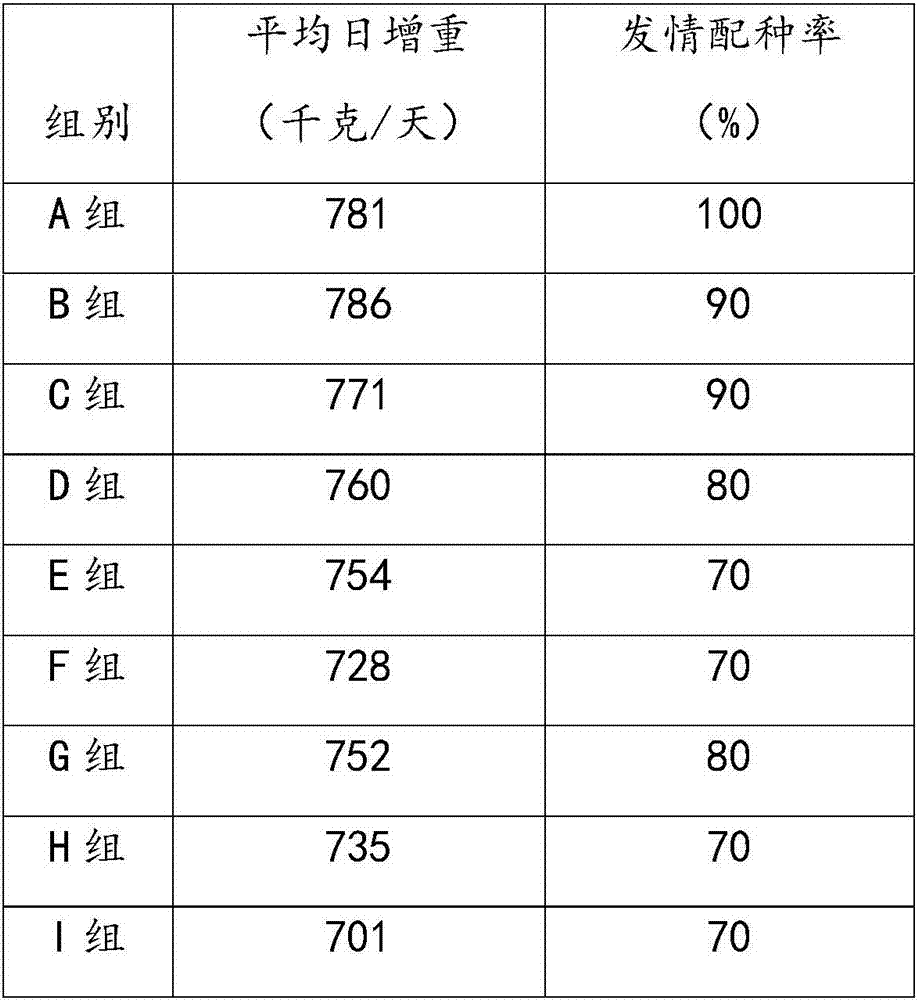

[0069] The above-mentioned functional compound dietary fiber is added to pig feed, and is applied to breeding boars, gilts, pregnant sows and lactating sows.

Embodiment 1

[0072] The functional composite dietary fiber provided in Example 1 includes 170 parts of alfalfa powder, 120 parts of seaweed powder, 170 parts of beet pulp, 120 parts of banana peel powder, 120 parts of puffed linseed, 40 parts of dehydrated celery powder, 40 parts of wood fiber, fish oil 15 parts, 12 parts of soybean oil, 12 parts of coconut oil, 12 parts of peanut oil, 2 parts of plant lactic acid bacteria, 1 part of Enterococcus faecalis and 7 parts of zeolite powder.

Embodiment 2

[0074] The functional composite dietary fiber provided in Example 2 includes 150 parts of alfalfa powder, 100 parts of seaweed powder, 150 parts of beet pulp, 100 parts of banana peel powder, 100 parts of puffed linseed, 30 parts of dehydrated celery powder, 30 parts of wood fiber, fish oil 10 parts, 10 parts of soybean oil, 10 parts of coconut oil, 10 parts of peanut oil, 1 part of plant lactic acid bacteria, 1 part of Enterococcus faecalis and 5 parts of zeolite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com