Reaction kettle capable of adjusting temperature

A technology for adjusting temperature and reaction kettle, which is applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc. It is not very convenient, the contact between the material and the catalyst is not uniform and sufficient, etc., to achieve the effect of good discharge, easy pneumatic isolation, and strong filterability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

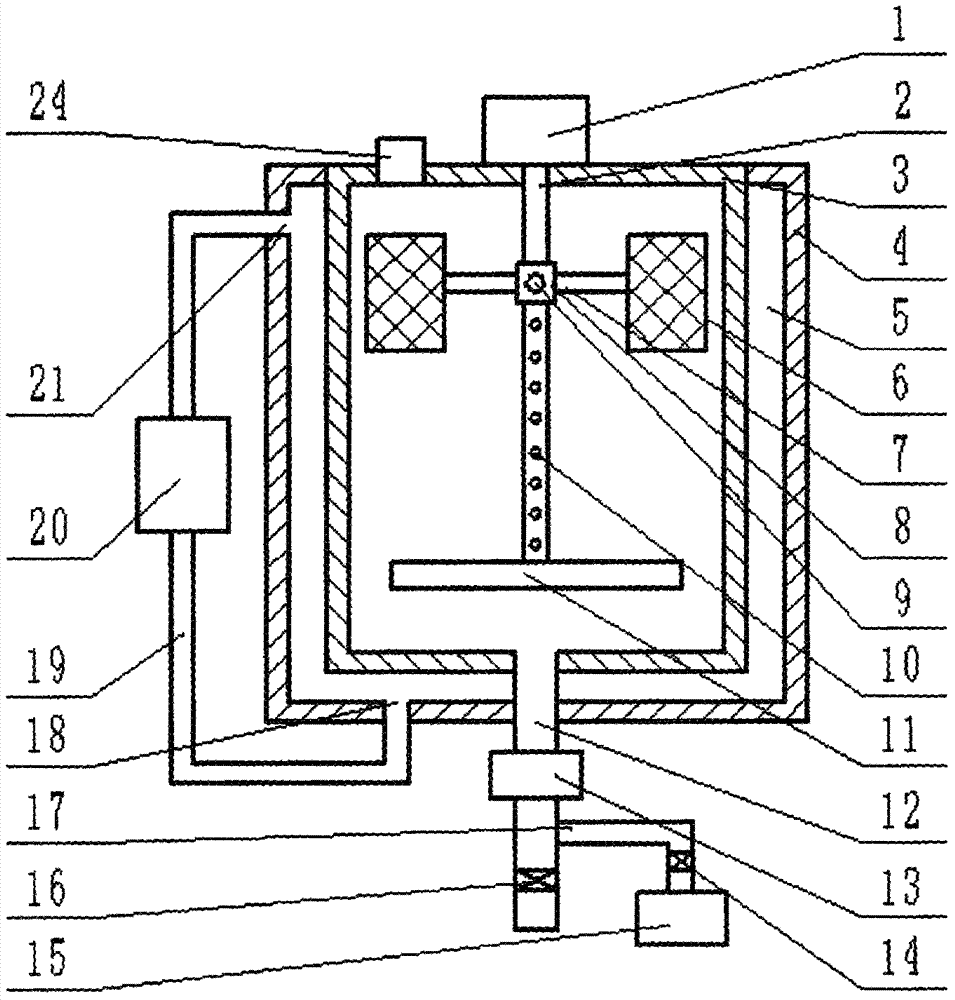

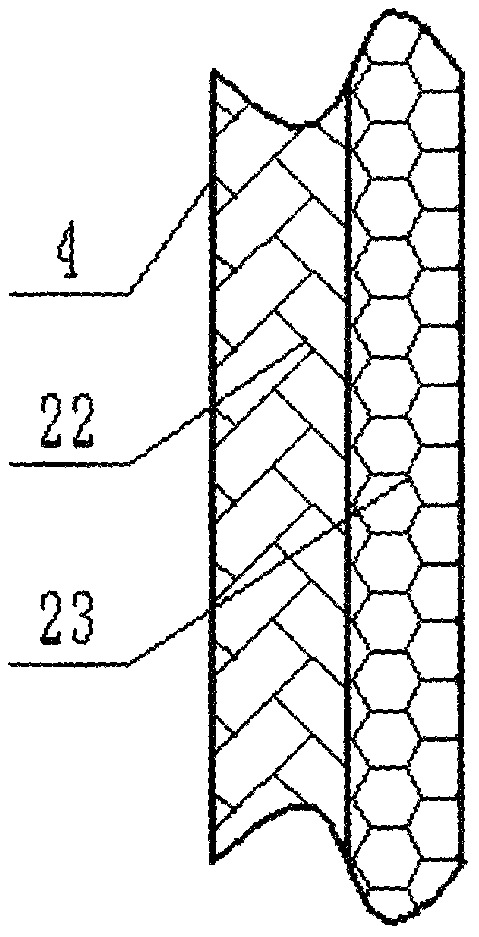

[0017] See Figure 1-2 , A reaction kettle capable of adjusting temperature, comprising a kettle body 3, an insulation layer 4 and a motor 1. The upper left side of the kettle body 3 is connected with a feed pipe 24, and the upper end of the kettle body 3 is fixedly installed with a motor 1. The output shaft of the motor 1 is connected with a stirring shaft 2; the stirring shaft 2 is provided with a plurality of threaded holes 10, the stirring shaft 2 is provided with a shaft sleeve 8, and the shaft sleeve 8 is provided with a bolt 9; Two connecting rods 7 are fixedly connected on both sides, and the end of the connecting rod 7 is fixedly connected with a containing frame 6; the bottom middle of the kettle body 3 is connected with a discharge pipe 12, and the discharge pipe 12 is provided with a pneumatic isolation The pump 13, the lower end of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com