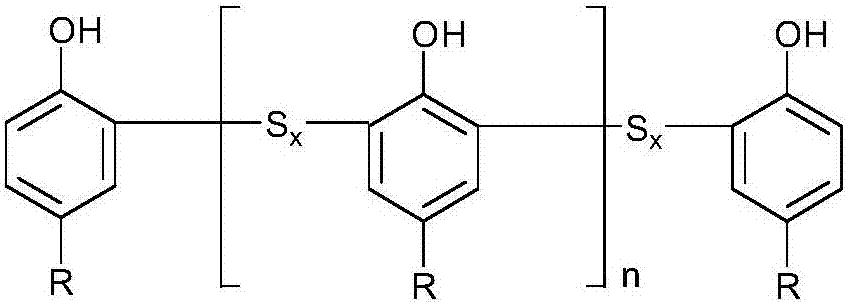

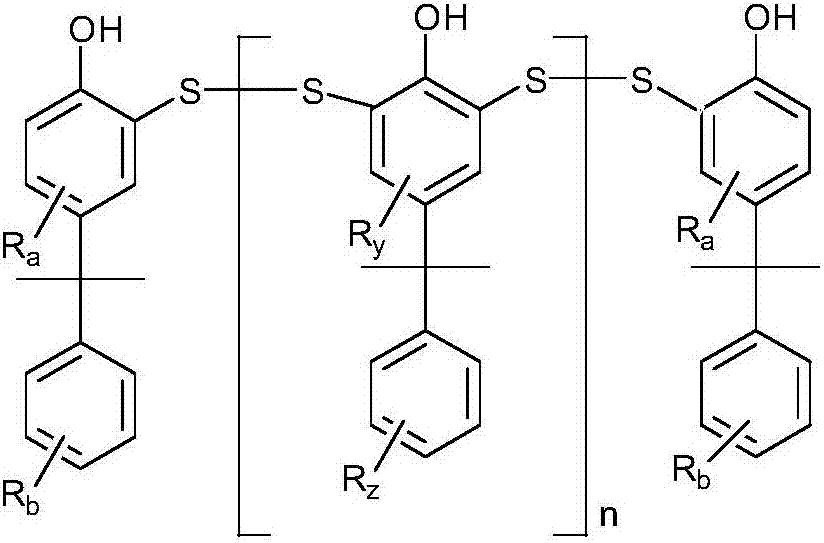

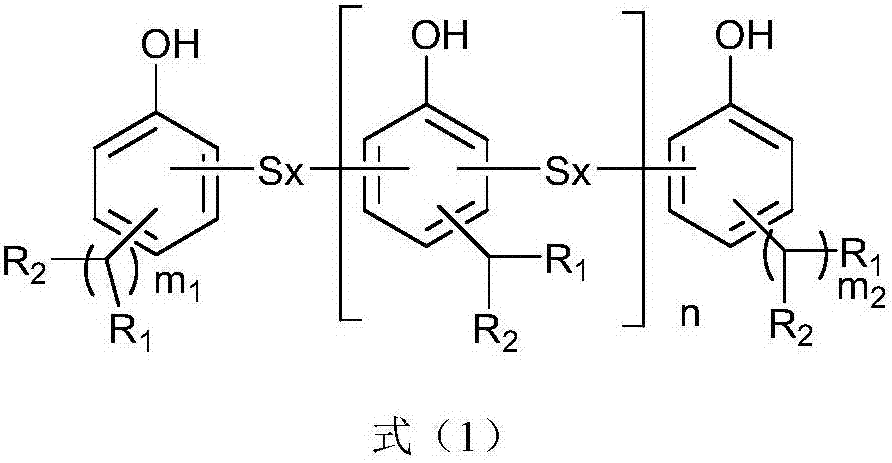

Alkylphenol sulfide, method for preparing same and application of alkylphenol sulfide

A technology of alkylphenol and sulfide, which is applied in the field of alkylphenol sulfide for the rubber industry. It can solve the problems of alkylphenol type restrictions and resin expansion restrictions, and achieve excellent mechanical properties, good mechanical properties, and accelerated reactivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] 2. Preparation of alkylphenol sulfides

[0063] Unless otherwise stated, the softening point was tested according to ASTM D3461-14, and the sulfur content was tested according to GB T4497.1-2010.

Embodiment 1

[0065] Add 79.2g (0.4mol) of styrenated phenol, 30.2g (0.1mol) of distyrenated phenol, and 90g of toluene into a 500ml reaction flask equipped with a stirring device, a thermometer and a reflux condenser, and gradually add 64.8g of S 2 Cl 2 (0.48mol), while gradually raising the temperature to 85°C, reflux reaction for 2h, and then raising the temperature to 170°C for vacuum distillation to obtain the product with a softening point of 84.6°C and a sulfur content of 23.7%.

Embodiment 2-5

[0067] The preparation process of the resin in Example 1 was repeated except changing the molar ratio of raw materials styrenated phenol and distyrenated phenol. See Table 2 below for specific data.

[0068] Table 2

[0069] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com