Photo-induced reversible macromolecular shrink film and preparation method thereof

A polymer, shrink film technology, applied in flat products, other household appliances, applications, etc., can solve the problems of high cost and complex modification process, and achieve the effect of low cost and high reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

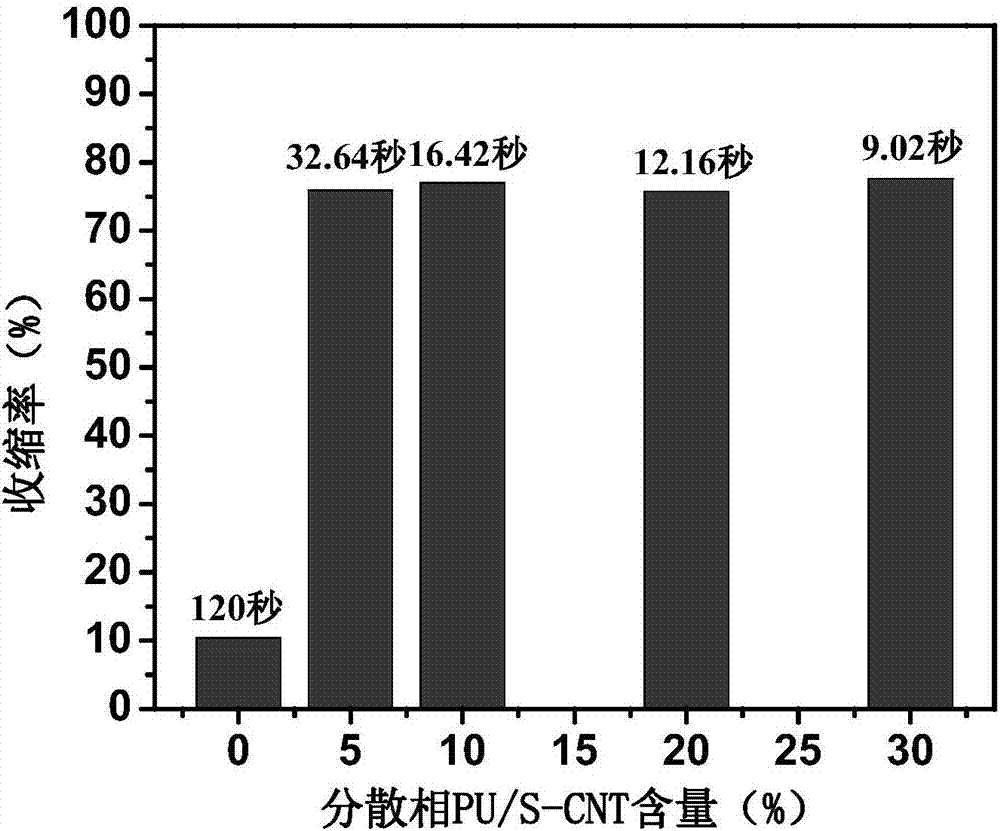

[0050] Example 1 Preparation of Photopolymer Shrink Film

[0051] The photopolymer shrink film is prepared by the following steps:

[0052] (1) Preparation of oxidized carbon nanotubes: carbon nanotubes are oxidized in a mixed solution of nitric acid / hydrochloric acid / water (nitric acid: hydrochloric acid: water = 1:1:1, volume ratio) at 80°C for 4 hours with magnetic stirring and centrifuged to obtain carbon dioxide Nanotubes were washed with distilled water and dried for later use; the mass fraction of carbon nanotubes in the mixture was 0.5wt%, the oxidation temperature was 80°C, and the oxidation time was 4h;

[0053] (2) Preparation of sulfonated carbon nanotubes: add oxidized carbon nanotubes in (1) to obtain a suspension after adding distilled water to ultrasonic for 1 h (the mass fraction of oxidized carbon nanotubes in the resulting suspension is 0.25wt%), and the suspension is added dropwise to The hydrochloric acid solution (in the hydrochloric acid solution) that ...

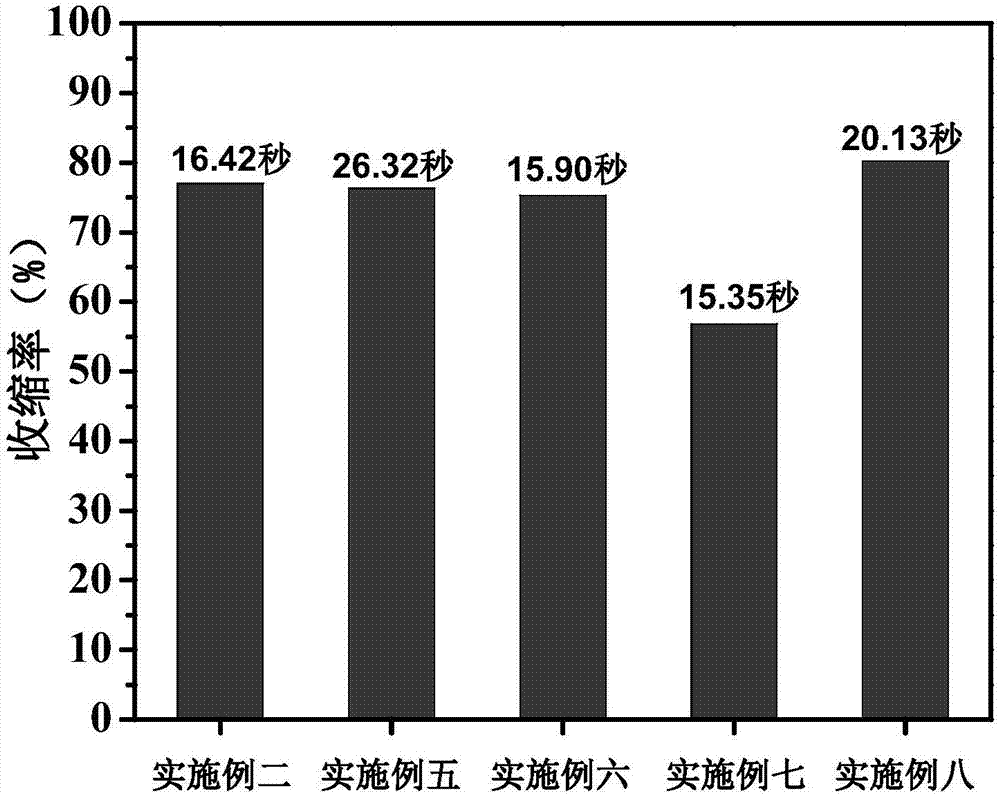

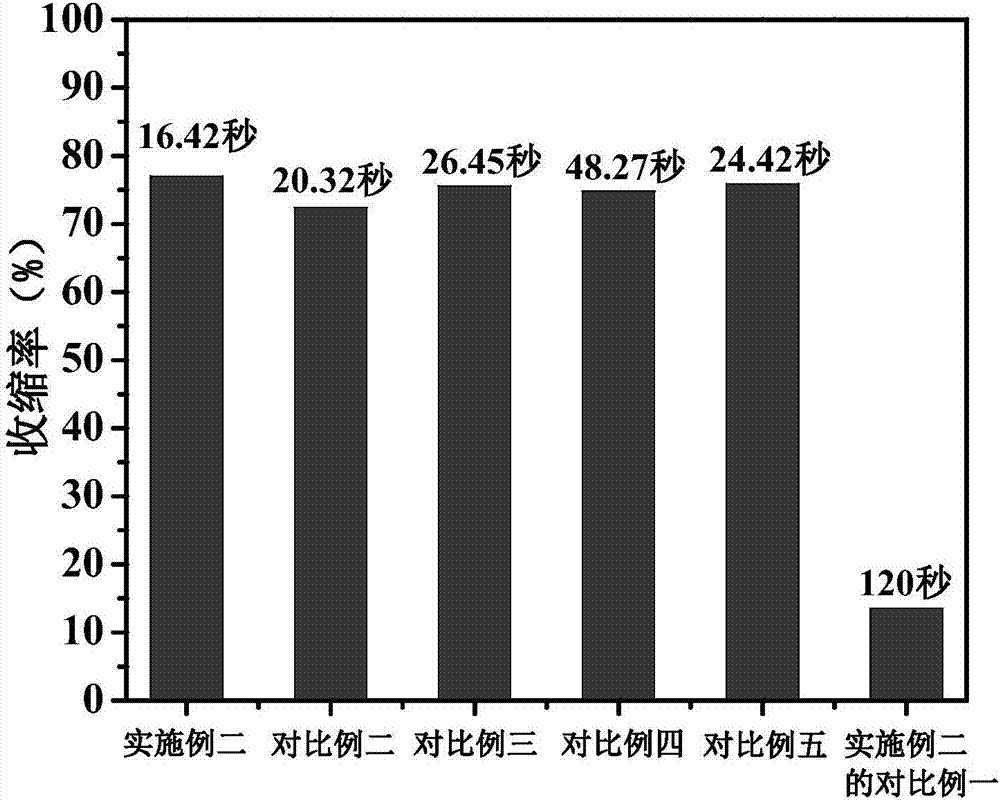

Embodiment 2

[0060] Example 2 Preparation of Photopolymer Shrink Film

[0061] The photopolymer shrink film is prepared by the following steps:

[0062] (1) Preparation of oxidized carbon nanotubes: carbon nanotubes are oxidized in a mixed solution of nitric acid / hydrochloric acid / water (nitric acid: hydrochloric acid: water = 1:1:1, volume ratio) at 80°C for 4 hours with magnetic stirring and centrifuged to obtain carbon dioxide Nanotubes were washed with distilled water and dried for later use; the mass fraction of carbon nanotubes in the mixture was 0.5wt%, the oxidation temperature was 80°C, and the oxidation time was 4h;

[0063] (2) Preparation of sulfonated carbon nanotubes: add oxidized carbon nanotubes in (1) to obtain a suspension after adding distilled water to ultrasonic for 1 h (the mass fraction of oxidized carbon nanotubes in the resulting suspension is 0.25wt%), and the suspension is added dropwise to The hydrochloric acid solution (in the hydrochloric acid solution) that ...

Embodiment 3

[0074] Example 3 Preparation of Photopolymer Shrink Film

[0075] The photopolymer shrink film is prepared by the following steps:

[0076] (1) Preparation of oxidized carbon nanotubes: carbon nanotubes are oxidized in a mixed solution of nitric acid / hydrochloric acid / water (nitric acid: hydrochloric acid: water = 1:1:1, volume ratio) at 80°C for 4 hours with magnetic stirring and centrifuged to obtain carbon dioxide Nanotubes were washed with distilled water and dried for later use; the mass fraction of carbon nanotubes in the mixture was 0.5wt%, the oxidation temperature was 80°C, and the oxidation time was 4h;

[0077] (2) Preparation of sulfonated carbon nanotubes: add oxidized carbon nanotubes in (1) to obtain a suspension after adding distilled water to ultrasonic for 1 h (the mass fraction of oxidized carbon nanotubes in the resulting suspension is 0.25wt%), and the suspension is added dropwise to The hydrochloric acid solution (in the hydrochloric acid solution) that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com