High-toughness ultra-weather-resistant heat-transferrable powder paint composition

A powder coating and super weather-resistant technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of strong coating film rigidity, high cross-linking density, and poor toughness, achieve clear pattern aesthetics, and improve toughness , the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

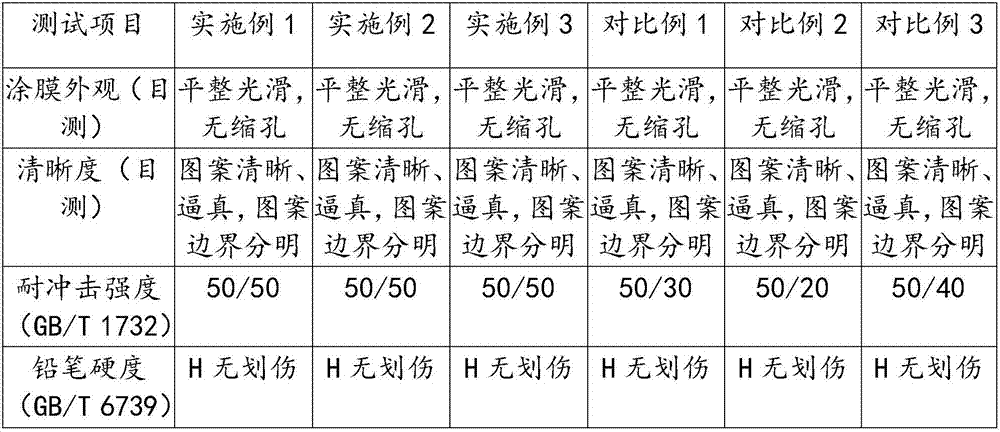

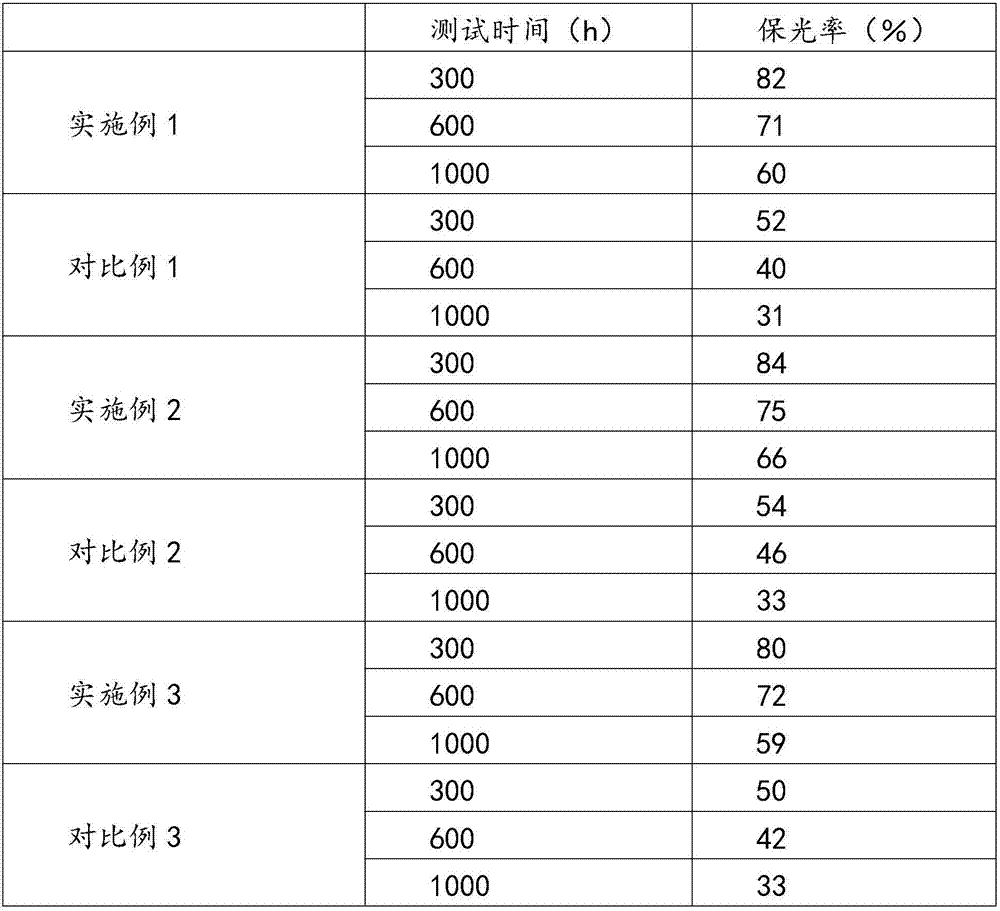

Examples

Embodiment 1

[0034] (1) 10g of trifluoroethyl acrylate, 8g of hydroxyethyl acrylate, 5g of methoxypolyethylene glycol acrylate monomer, 75g of styrene, and 1g of azobisisovaleronitrile are made into a monomer mixture . 100g of toluene was added into a 500ml three-neck flask and stirred at elevated temperature. When the solvent was refluxed, the monomer mixture was added dropwise, and the dropwise addition was completed in 2-2.5 hours, and the reflux and heat preservation reaction was continued for 2 hours. Concentrate and remove the solvent under reduced pressure, the temperature does not exceed 170 ° C, discharge while hot, cool, and coarsely pulverize to obtain a polymer additive with a Tg of 80 ° C and a number average molecular weight of 21200;

[0035] (2) A high-toughness and super-weather-resistant heat-transferable powder coating composition, comprising the following weight component raw materials:

[0036] Super Weatherable Polyester Resin 60%;

[0037] TGIC curing agent 4.5%; ...

Embodiment 2

[0056] (1) 15g of pentafluoropropyl acrylate, 12g of hydroxypropyl acrylate, 13g of methoxypolyethylene glycol acrylate monomer, 57g of ethyl acrylate, and 1g of azobisisovaleronitrile are made into monomers mixture. 100g of toluene was added into a 500ml three-neck flask and stirred at elevated temperature. When the solvent was refluxed, the monomer mixture was added dropwise, and the dropwise addition was completed in 2-2.5 hours, and the reflux and heat preservation reaction was continued for 2 hours. Concentrate and remove the solvent under reduced pressure, the temperature does not exceed 170°C, discharge while hot, cool, and coarsely pulverize to obtain a polymer additive with a Tg of 67°C and a number average molecular weight of 14,500;

[0057] (2) A high-toughness and super-weather-resistant heat-transferable powder coating composition, comprising the following weight component raw materials:

[0058] Super Weatherable Polyester Resin 65%;

[0059] TGIC curing agen...

Embodiment 3

[0078] (1) 15g of trifluoroethyl acrylate, 12g of hydroxypropyl acrylate, 13g of methoxypolyethylene glycol acrylate monomer, 57g of ethyl methacrylate, and 1g of azobisisovaleronitrile monomer mixture. 100g of toluene was added into a 500ml three-neck flask and stirred at elevated temperature. When the solvent was refluxed, the monomer mixture was added dropwise, and the dropwise addition was completed in 2-2.5 hours, and the reflux and heat preservation reaction was continued for 2 hours. Concentrate and remove the solvent under reduced pressure, the temperature does not exceed 170 ° C, discharge while hot, cool, and coarsely pulverize to obtain a polymer additive with a Tg of 50 ° C and a number average molecular weight of 8300;

[0079] (2) A high-toughness and super-weather-resistant heat-transferable powder coating composition, comprising the following weight component raw materials:

[0080] Super Weatherable Polyester Resin 63%;

[0081] TGIC curing agent 4.8%;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com