Adaptive variable molten pool laser additive manufacturing process

A laser additive and manufacturing technology, applied in additive processing, additive manufacturing, process efficiency improvement, etc., can solve problems such as difficulty in realization, and achieve the effect of easy real-time control, less variables, and high forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

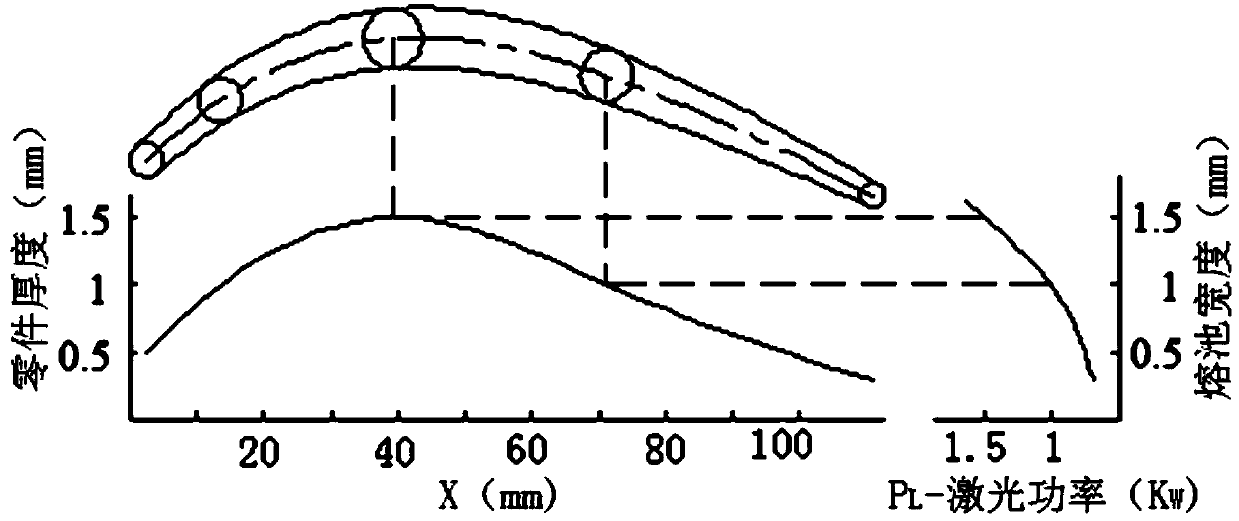

[0034] Taking the laser additive manufacturing of superalloy GH150 turbine blades as an example, the process plan of adaptive variable molten pool laser additive manufacturing is explained:

[0035] When the laser fusion test, the process parameters used are: scanning speed is 4mm / s, defocus is 5mm, spot diameter is 3mm, and argon flow is 11L / min. By changing the laser power, the superalloy GH150 is established. Process database of laser power and molten pool size;

[0036] The laser cladding powder is superalloy GH150 spherical powder with a particle size of 75-150μm. Before cladding, the superalloy GH150 spherical powder must be dried under vacuum conditions at about 120°C to remove the adsorbed moisture in the powder;

[0037] The LDM8060 laser processing system is composed of YLS-6000 fiber laser, TWIN PF 2 / 2-MF powder feeding system, three-axis linkage numerical control table, lateral powder feeding nozzle and argon protective box, etc. The thickness of each layer of cladding la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com