High-concentration graphene slurry, and preparation method and preparation device thereof

A preparation device and graphene technology, applied in the field of graphene, can solve problems such as high energy consumption, increase cost, increase preparation process, etc., and achieve the effects of simple preparation process, improved mechanization, and reduced preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a preparation method of graphene slurry.

[0041] The preparation method of the graphene slurry provided by the present invention comprises weighing expanded graphite, a dispersant and a solvent, and dividing the expanded graphite into N parts, which are respectively the first expanded graphite, ..., the Nth Expanded graphite, the N is greater than or equal to 2, the dispersant is divided into M parts, respectively the first dispersant, ..., the M dispersant, the M is greater than or equal to 2 ; The first expanded graphite, the first dispersant and all solvents are first stirred, and the first mixed solution is obtained after stirring; the first mixed solution is placed in an ultrasonic system, and graphene is obtained after ultrasonic Slurry precursor; Stir remaining expanded graphite and dispersant in batches, and add in batches to described ultrasonic system, after ultrasonic, obtain described graphene slurry, by mass percentage, described Th...

Embodiment 1

[0060] Prepare 10kg of aqueous slurry whose concentration of graphene slurry is 10wt%. The dispersant is polyvinylpyrrolidone, and the mass ratio of polyvinylpyrrolidone and expanded graphite is 0.3. Calculate the expanded graphite required for the slurry to be 1 kg, the dispersant to be 0.3 kg, and the total mass of the solvent to be 8.7 kg.

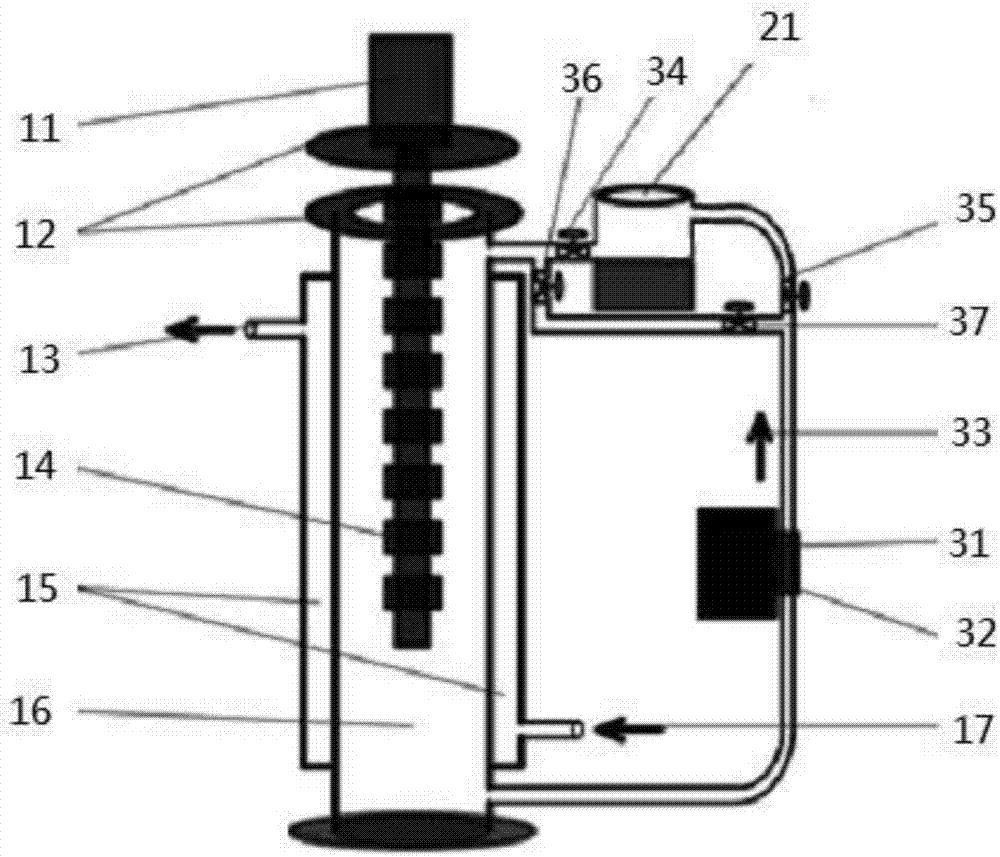

[0061] The preparation device of the graphene slurry that present embodiment provides is as figure 1 shown. In the device provided in this embodiment, the ultrasonic system includes a flange 11 of the ultrasonic device, a flange 12 of the ultrasonic device, a water outlet 13 of the water wall, an energy-concentrating ultrasonic rod 14, a water wall 15, an ultrasonic system reactor cavity 16, and a water cooling wall. Wall water inlet 17; peristaltic pump 31 includes peristaltic pump head 32. At this time, the first switch 34 , the second switch 35 , the third switch 36 and the fourth switch 37 are all in the off state.

[0062] The ...

Embodiment 2

[0073]Prepare 20kg of NMP phase slurry whose graphene slurry concentration is 5wt%. The dispersant is polyoxypropylene-polyoxyethylene copolymer, and the mass ratio of dispersant to expanded graphite is 0.2. Calculate the expanded graphite required for the slurry to be 1 kg, the dispersant to be 0.2 kg, and the total mass of the solvent to be 18.8 kg.

[0074] Step 1: Stir 0.25kg of expanded graphite, 0.05kg of polyoxypropylene-polyoxyethylene copolymer, and 18.8kg of water in the stirring system 21, and use a peristaltic pump 31 to slowly place the materials in the stirring system in the ultrasonic system. The circulating liquid volume of the pump is 15kg / min, and the ultrasonic reaction system is turned on, so that all the materials in the stirring system enter the reaction kettle cavity 16 of the ultrasonic system;

[0075] Step 2: Open the third switch 36 and the fourth switch 37, close the first switch 34 and the second switch 35, and ultrasonically peel to D50<3um, D90<...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com