Cutting fluid recovery treatment system and cutting fluid recovery treatment method

A treatment system and recycling technology, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve problems such as failure to pass national discharge standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

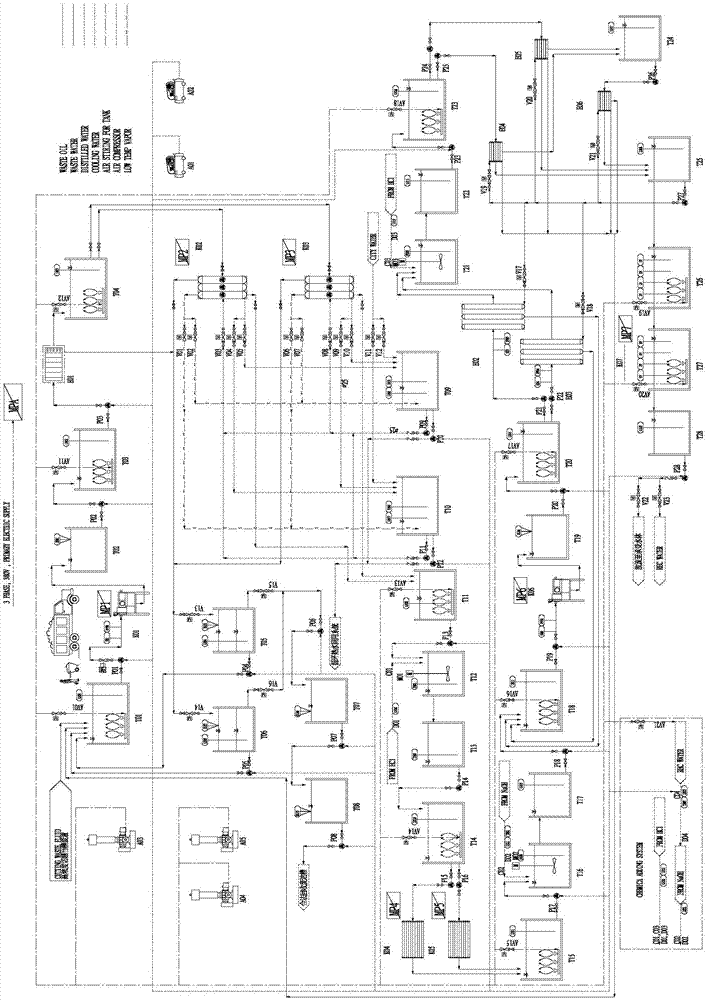

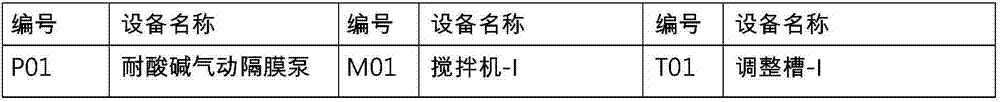

[0049] See attached figure 1 As shown, the cutting fluid recovery processing system and processing method in this embodiment include

[0050] 1. The first stage - dandruff and oil removal

[0051] 1. Actions before the system starts

[0052] Fill the circulation tank-IT09 and circulation tank-IIT10 with tap water to the highest water level; then repeatedly fill the discharge tank T28 with water to the medicine barrel D04; so that the medicine in D02 and D04 is completed.

[0053] 2. Soak medicine

[0054] Manually open the pipeline valve V23, close the valve V22, and the pump P28 is in the "ON" state to recycle the water (REC WATER) in the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com