Complex ceramic and preparation method and application thereof

A composite ceramic and formula technology, applied in the field of ceramic materials, can solve the problems of weak antibacterial ability and poor health care effect, and achieve the effect of improving function, low cost and eliminating fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

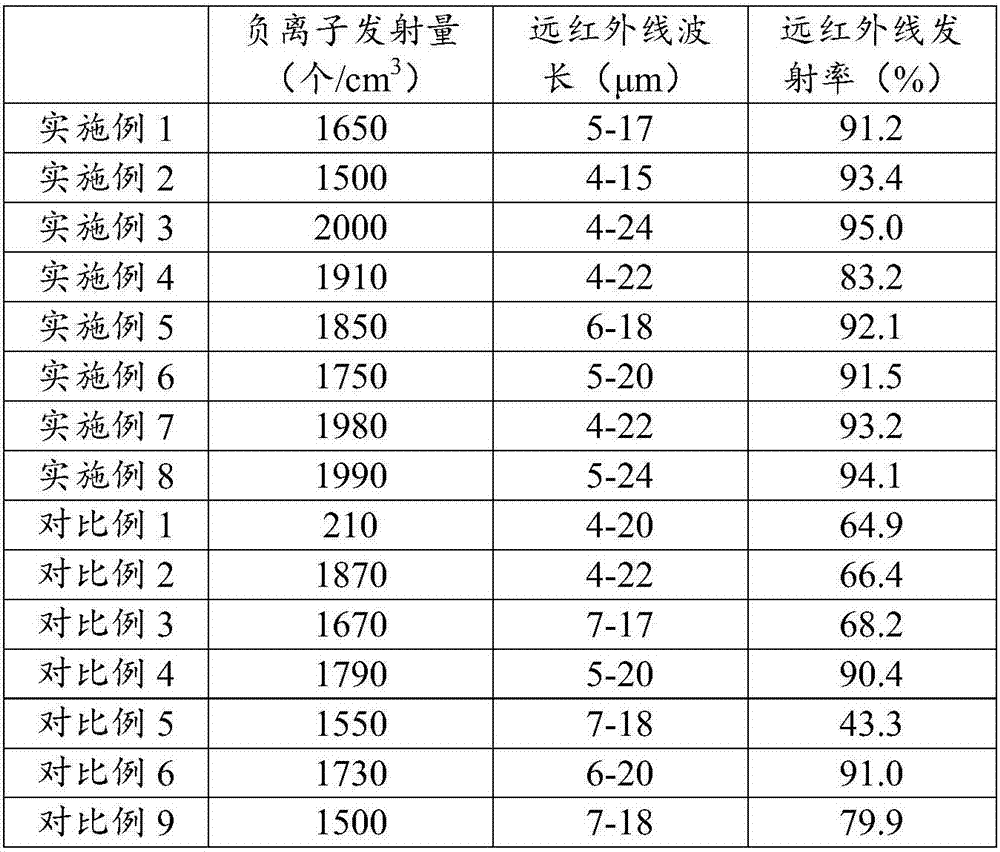

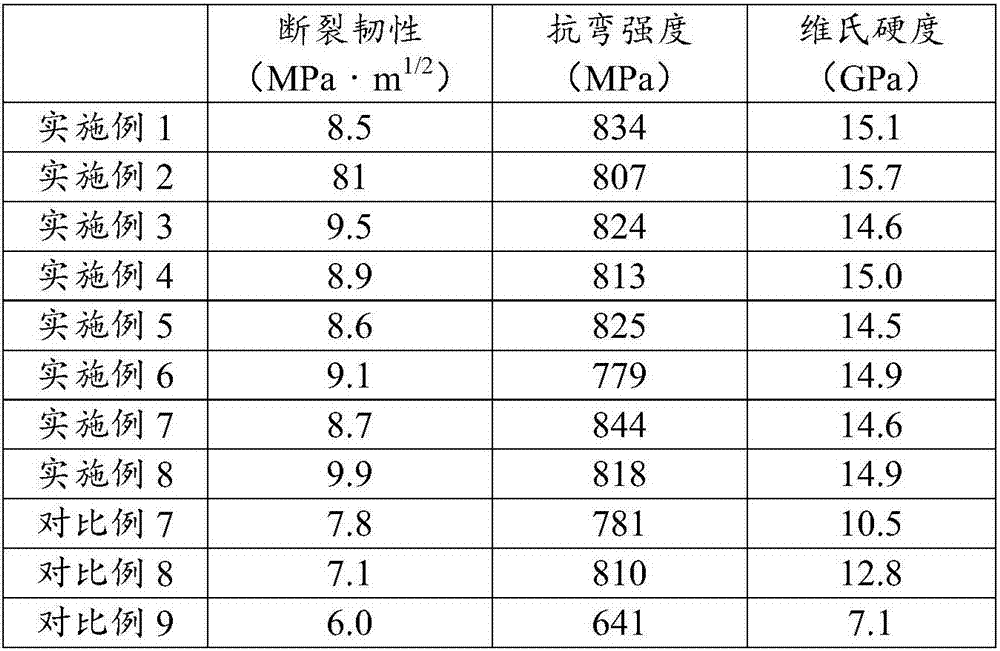

Examples

preparation example Construction

[0057] According to another aspect of the present invention, the embodiment of the present invention also provides a method for preparing the above-mentioned composite ceramics, comprising the following steps: mixing MgO, SiO 2 , MnO 2 、Al 2 o 3 、Cr 2 o 3 , ZrO 2 , SiC, TiO 2 , monomer carbon, negative ion powder, germanium stone, volcanic stone and kaolin are added to the ball mill according to the formula ratio, and an optional cationic dispersant is added, the ball mill is uniform, and iron is removed by sieving, and the slurry is made after heating and activation. molding, dewaxing, sintering, and polishing to obtain composite ceramics; preferably, the molding method is hot die-casting.

[0058] The above preparation method prepares the composite ceramics by ball milling and mixing the raw material components and then hot die-casting, which not only can effectively ensure the dimensional accuracy of the composite ceramic products, but also can leave uniform pores in ...

Embodiment 1

[0079] According to weight percentage, take the following preparation raw materials: MgO 10%, SiO 2 10%, MnO 2 10%, Al 2 o 3 10%, Cr 2 o 3 10%, ZrO 2 10%, SiC 15%, TiO 2 4%, monomer carbon 1%, negative ion powder 4%, germanium stone 3%, volcanic stone 3%, kaolin 10%.

[0080] The preparation method of composite ceramics is: MgO, SiO 2 , MnO 2 、Al 2 o 3 、Cr 2 o 3 , ZrO 2 , SiC, TiO 2 , monomer carbon, negative ion powder, germanium stone, volcanic stone and kaolin are added to the ball mill according to the formula ratio, and an optional cationic dispersant is added, and the dry ball mill is carried out for 48 hours. After heating and activating at ℃ for 4 hours, add beeswax and a special dispersant for ceramics to make a slurry, carry out hot die casting, wax removal, sinter at 1000 ℃ for 5 hours, and polish to obtain composite ceramics.

Embodiment 2

[0082] According to weight percentage, take the following preparation raw materials: MgO 6%, SiO 2 5%, MnO 2 9%, Al 2 o 3 5%, Cr 2 o 3 8%, ZrO 2 6%, SiC 40%, TiO 2 1%, monomer carbon 1.5%, negative ion powder 1%, germanium stone 5%, volcanic stone 4%, kaolin 8.5%.

[0083] The preparation method of composite ceramics is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com