Lurasidone hydrochloride-amino acid coamorphous material

A technology of lurasidone hydrochloride and amorphous substance, applied in the field of medicine, can solve the problems of low dissolution rate, poor water solubility, low oral bioavailability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

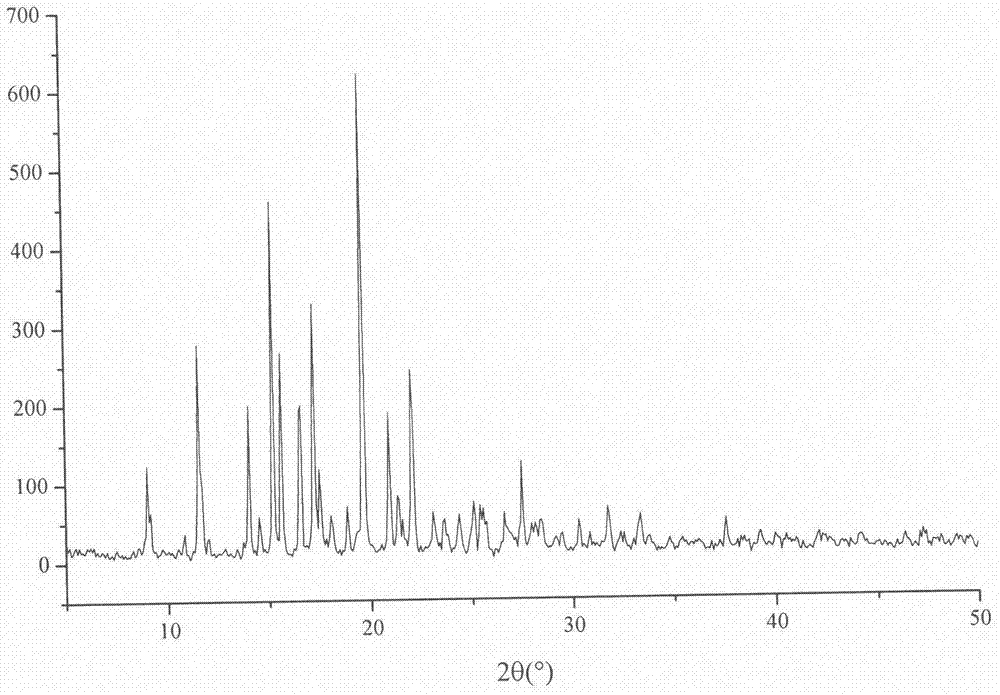

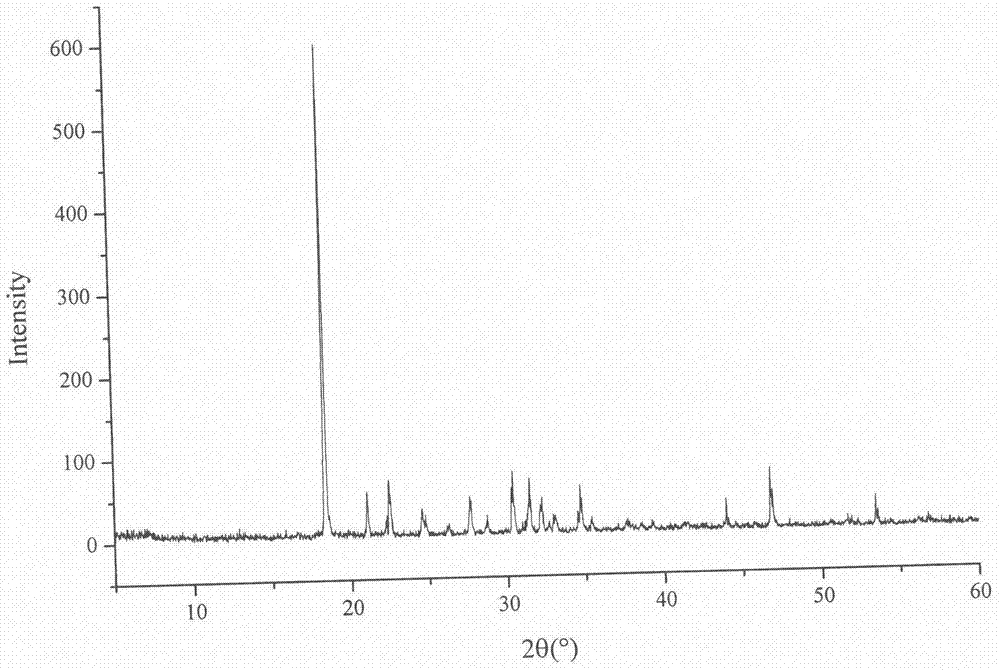

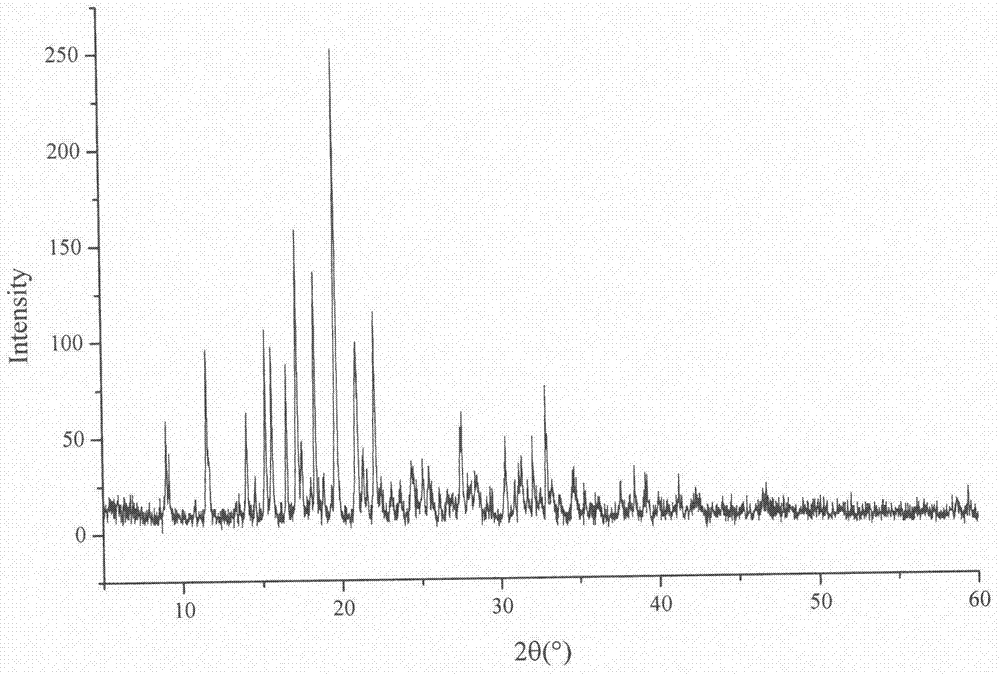

Image

Examples

Embodiment 1

[0064] Example 1: Preparation of lurasidone hydrochloride L-cysteine hydrochloride co-amorphous

[0065] Add 0.50g of lurasidone hydrochloride and 0.15g of L-cysteine hydrochloride into 250mL of ethanol, and ultrasonically dissolve at room temperature to obtain a clear solution. Rotate the solvent under reduced pressure at 40°C to dry the clear solution under vacuum at 25°C. After 24 hours, 0.38 g of white powder was obtained.

Embodiment 2

[0066] Example 2: Preparation of lurasidone hydrochloride L-cysteine hydrochloride co-amorphous

[0067] Add 0.50g of lurasidone hydrochloride and 0.15g of L-cysteine hydrochloride into 50mL of methanol, and ultrasonically dissolve at room temperature to obtain a clear solution. Rotate the solvent under reduced pressure at 50°C to dry the clear solution under vacuum at 25°C. After 24 hours, 0.53 g of white powder was obtained.

Embodiment 3

[0068] Example 3: Preparation of lurasidone hydrochloride L-cysteine hydrochloride co-amorphous

[0069] Add 0.50 g of lurasidone hydrochloride and 0.15 g of L-cysteine hydrochloride into 60 mL of methanol-ethanol (50:50, v / v) mixed solvent, and ultrasonically dissolve at room temperature to obtain a clear solution. The solvent was rotary evaporated under reduced pressure at 45°C, and dried in vacuum at 25°C for 24 hours to obtain 0.51 g of white powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com