Preparation and application of amino-functionalized MOFs material

A technology of amino functionalization and catalytic reaction, which is applied in the field of metal-organic framework material preparation, can solve the problems of few application reports, and achieve the effect of expanding the application field and making the preparation method simple and feasible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

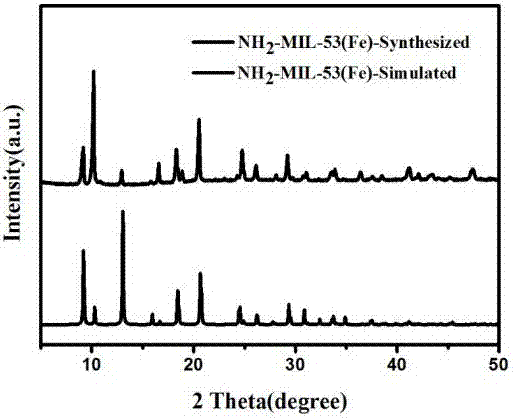

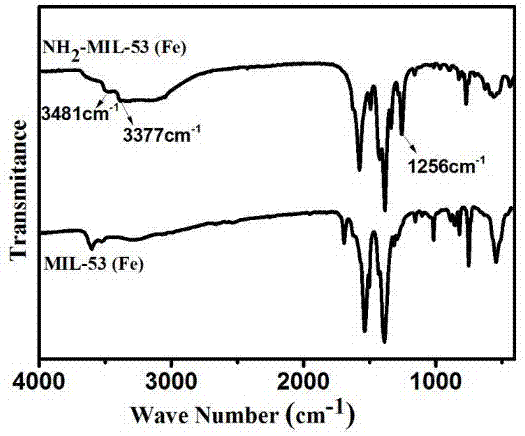

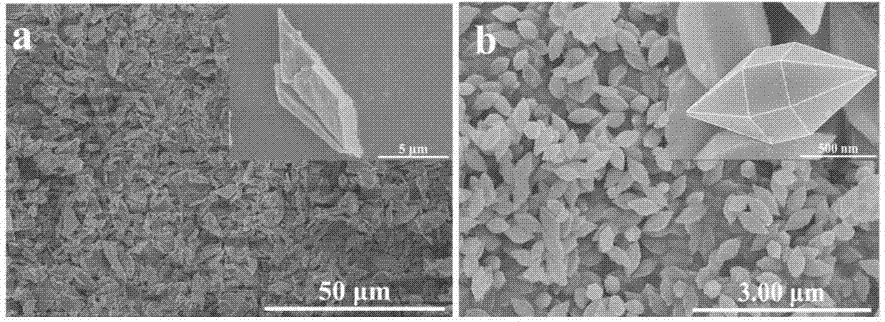

Embodiment 1

[0035] 0.370 g organic ligand H 2 ATA and 0.808 g Fe(NO 3 ) 2 9H 2 O was dissolved in 20 mL of DMF solution, ultrasonicated for 20 min at 100 W to disperse and dissolve evenly. The obtained solution was transferred to the lining of a polytetrafluoroethylene autoclave, and the autoclave was sealed and placed in an oven at 140 °C for 6 h. After the reaction dropped to room temperature, the obtained product was washed with methanol, centrifuged several times, dried at 80 °C for 4 h, and then treated under static vacuum at 80 °C for 8 h to finally obtain catalyst A.

Embodiment 2

[0037] 0.370 g organic ligand H 2 ATA and 0.808 g Fe(NO 3 ) 2 9H 2 O was dissolved in 20 mL of DMF solution, ultrasonicated for 20 min at 100 W to disperse and dissolve evenly. The obtained solution was transferred to the lining of a polytetrafluoroethylene autoclave, and the autoclave was sealed and placed in an oven at 150 °C for 6 h. After the reaction was cooled to room temperature, the obtained product was washed with methanol, centrifuged several times, dried at 80 °C for 4 h, and then treated under static vacuum at 80 °C for 8 h to finally obtain catalyst B.

Embodiment 3

[0039] 0.370 g organic ligand H 2 ATA and 0.808 g Fe(NO 3 ) 2 9H 2 O was dissolved in 20 mL of DMF solution, ultrasonicated for 20 min at 100 W to disperse and dissolve evenly. The obtained solution was transferred to the lining of a polytetrafluoroethylene high-pressure reactor, and the reactor was sealed and placed in an oven at 160 °C for 6 h. After the reaction was cooled to room temperature, the obtained product was washed with methanol, centrifuged several times, dried at 80 °C for 4 h, and then treated under static vacuum at 80 °C for 8 h to obtain catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com