Hybrid optical pumping-based accurate atomic density measurement method

A technology of atomic density and mixed light, applied in the measurement of color/spectral characteristics, measurement device, material analysis by optical means, etc., can solve the problems of poor measurement accuracy of absorbed light intensity, unusable, unmeasured, etc., to improve the measurement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

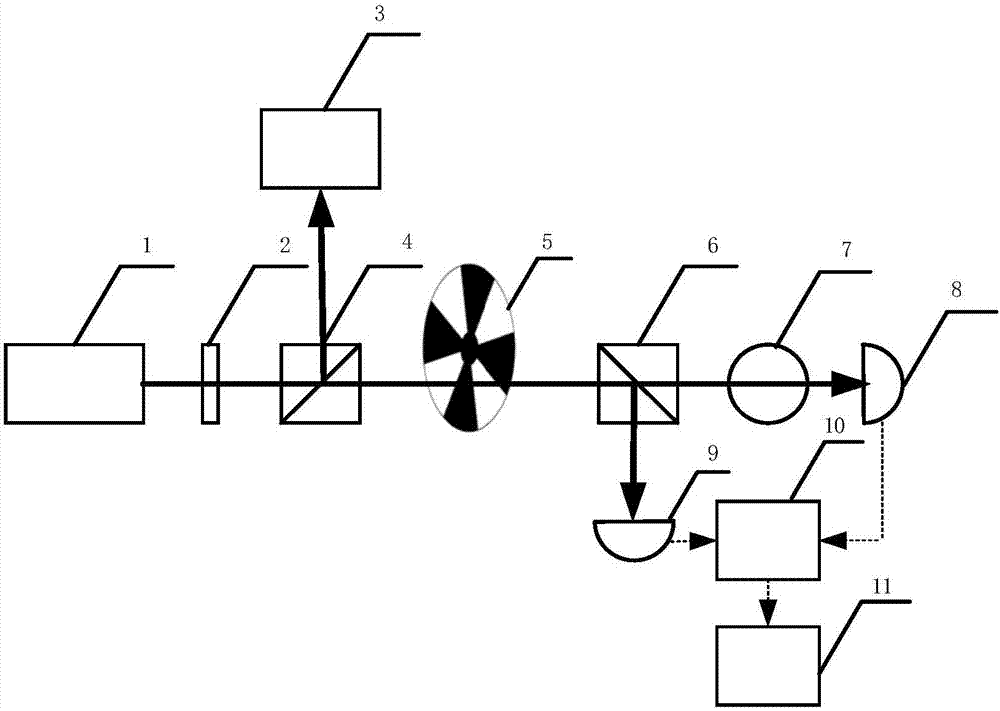

[0050] The present invention is based on the basic requirements of system design. The entire optical path system includes lasers, choppers, 1 / 2 wave plates, PBS, NPBS, lock-in amplifiers, wavelength meters, photoelectric detectors, alkali metal gas chambers and other additional data acquisition and display. equipment.

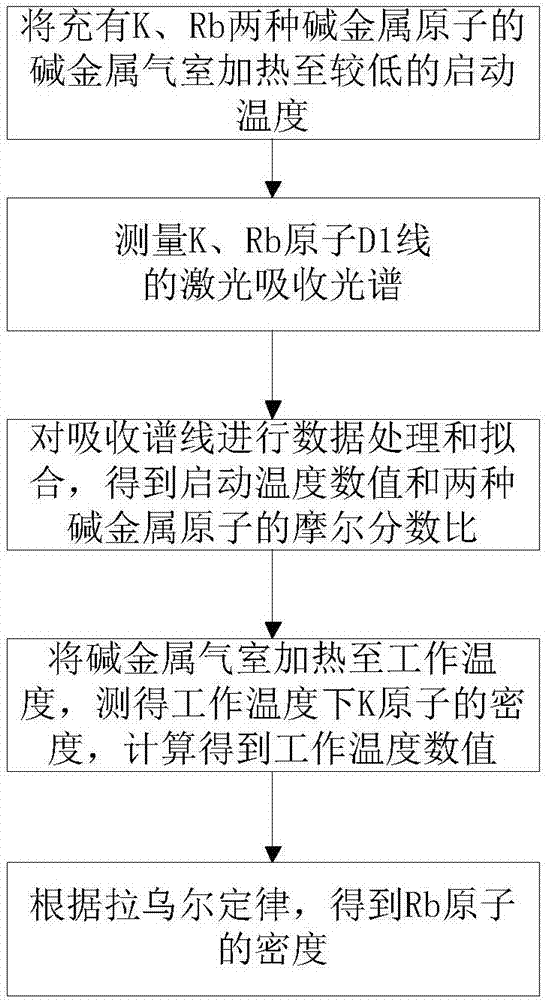

[0051] (1) Install the gas chamber filled with two kinds of alkali metal atoms of K and Rb to be measured in such as figure 2 In the experimental system shown, it was heated to a lower start-up temperature T1.

[0052] The laser output from the laser 1 passes through the wave plate 2 and the polarization 4 beam splitter and is divided into two beams of light. One beam is transmitted to the wavelength meter 3 to measure its frequency, and the other beam enters the chopper 6 to modulate the light. A depolarizing beam splitter 6 with a splitting ratio of 1:1, one beam enters the lock-in amplifier 10 through the photodetector 9 for demodulation, to reduce the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com