Method for preparing elastic linen fabric

A flax and fabric technology, applied in the processing of textile materials, fabric surface trimming, liquid/gas/vapor textile processing and other directions, can solve the problem that pure linen elastic fabrics have not been developed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

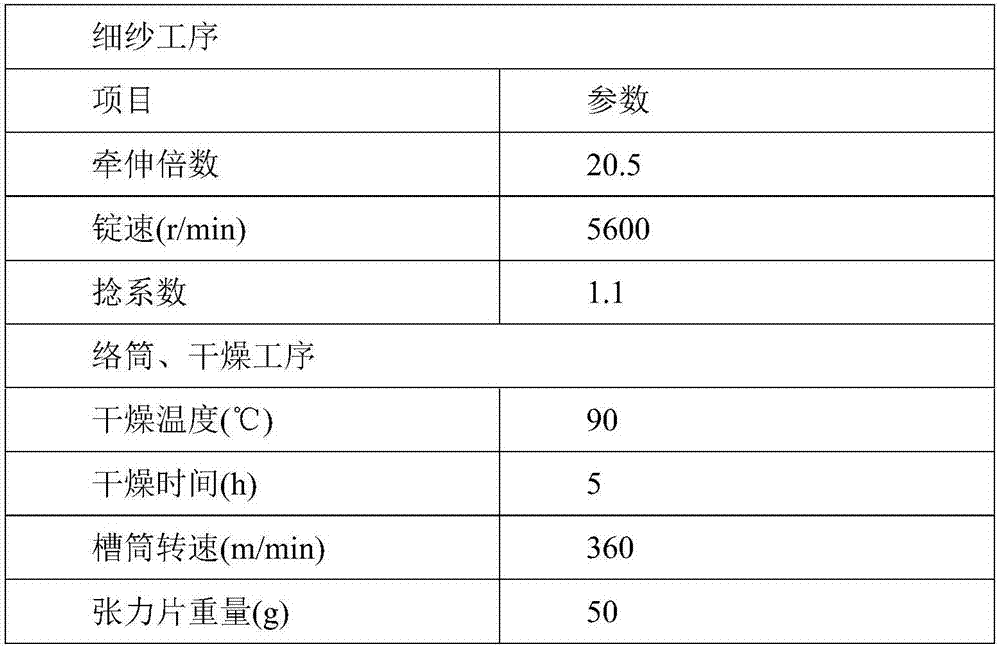

[0089] The preparation method of the flax elastic fabric of the present application is divided into two parts: the preparation of the flax elastic yarn and the preparation of the flax elastic fabric. Hemp, humidification and health preservation, combing machine 1, combing machine 2, sliver forming machine, 5-way drawing frame, roving, boiling and bleaching, spinning, drying, winding + filament, covering yarn machine, elastic yarn, packaging.

[0090] The raw flax is preferably raw flax with a splitting degree of more than 250 pieces. And prepare the linen elastic fabric according to the following steps. The specific steps are as follows:

[0091] Step 1: Beat the raw hemp into hemp, select the raw hemp whose splitting index is greater than or equal to 250 pieces, and beat the raw hemp into hemp;

[0092] Step 2: Humidification and health preservation, spray humidification on the branded hemp, and moisturize for 30-38 hours;

[0093] Step 3: combing, using a combing machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com