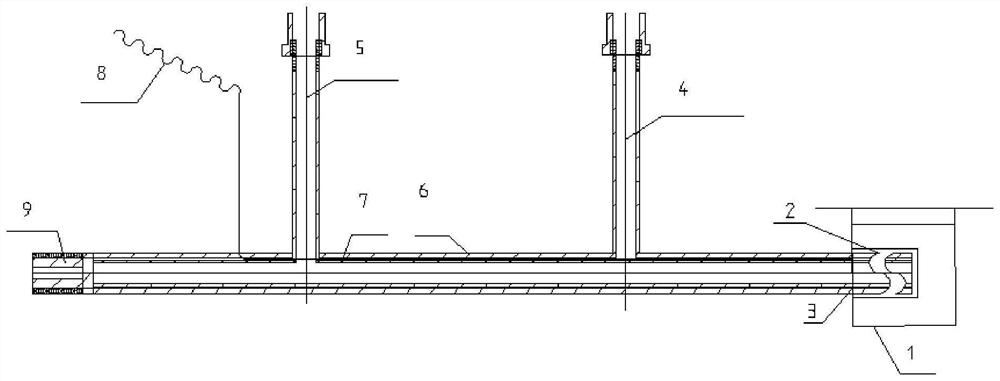

Method and device for promoting rapid temperature rise of blast furnace hearth

A blast furnace, fast technology, applied in blast furnaces, discharge devices, inspection devices, etc., can solve problems such as burning out, poor oxidation resistance, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0044]Specific implementation method 1. When the furnace is newly opened, that is, when there is no residual iron in the furnace hearth, first use a Ф60mm drill to clean the iron hole channel, and then burn the red coke with oxygen, and then punch 1 grid with water or anhydrous gun mud, and then withdraw the gun Then bury the gun directly. After burying it, add gun mud and compact it, and then turn on compressed air and oxygen, and gradually turn on from small to large. The pressure in the early stage is low and the pressure in the late stage is high. After half an hour, the gas pressure is: oxygen 0.25MPa, compressed air 0.4MPa, no air leakage. When burying the gun, plug the front end of the oxygen gun with a cone of wood. This method of opening the furnace can not draw the gun until the liquid level rises above the iron spout.

specific Embodiment approach 2

[0045] Specific implementation method 2: when the furnace is turned on after the furnace is closed or the hearth is frozen, first use a Ф60mm drill to clean the iron mouth channel, and then burn the red coke with oxygen, and then make 1 grid with water or anhydrous gun mud, and directly after the gun is withdrawn Bury the gun. After burying the gun, add gun mud and compact it, and then turn on compressed air and oxygen, gradually from small to large. The early pressure is low and the late pressure is high. After half an hour, the gas pressure is: oxygen 0.3MPa , Compressed air 0.4MPa, no air leakage, when burying the gun, plug the front end of the oxygen gun with a cone of wood.

specific Embodiment approach 3

[0046] Specific implementation mode three, the method of re-burying the rapid heating device after pulling out the rapid heating device: applicable to the case of freezing of the furnace hearth

[0047] A After the iron is finished, if the channel of the iron hole is large and the fluidity of the slag is good, after the hole is blocked (the amount of mud pumping can not deepen the iron hole, about 0.5 to 1 grid), and the gun is buried immediately after withdrawing the gun for 5 minutes.

[0048] B After the iron is tapped, if the channel of the iron hole is small and the fluidity of the slag and iron is poor, after the blockage is withdrawn, clean up the slag and iron around the iron hole, drill the iron hole with a drill, and block the hole immediately (0.5 to 1 grid of mud) , 5 minutes to withdraw the gun and immediately bury the gun.

[0049] The device and method ensure continuous oxygen supply and reduce the consumption of oxygen pipes; avoid heat loss when replacing oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com