System and method for treatment of waste ammonia distillation liquid through combination of calcium remover and nano-filtration membrane

A technology of distilling ammonia waste liquid and nanofiltration membrane, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problem of low industrial value and inapplicability of sodium chloride and calcium chloride products Large-scale industrial production, low industrial value of calcium chloride products, etc., to achieve a good demonstration effect, avoid waste, and reduce the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

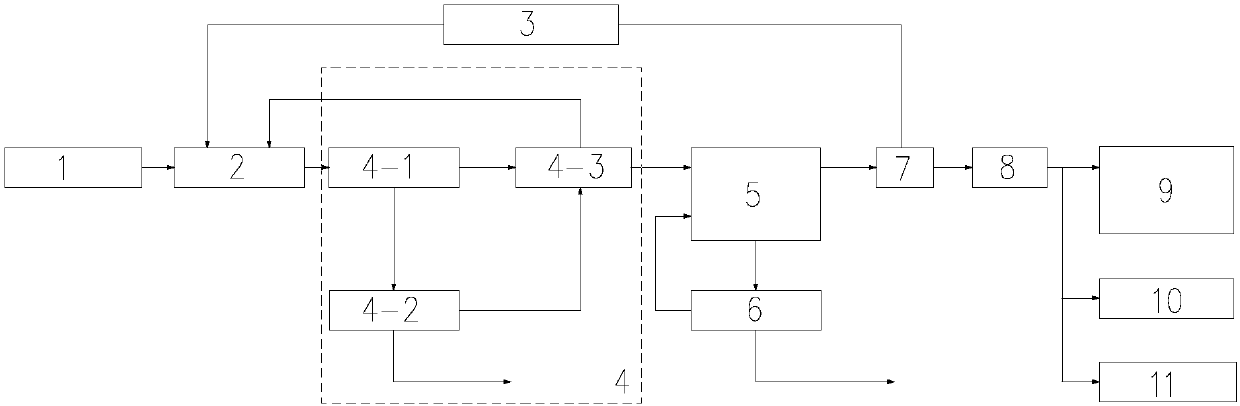

[0041] Embodiment 1: A system for treating waste ammonia distillation waste liquid in combination with a decalcifying agent and a nanofiltration membrane, which includes a waste ammonia distillation waste liquid regulating tank 1, a gypsum reaction tank 2, a decalcifying agent dissolving tank 3, a gypsum dehydration and drying device 4, Calcium carbonate reaction separation device 5, calcium carbonate dehydration and drying device 6, nanofiltration membrane system 7 and reuse storage tank 8;

[0042] The clear liquid outlet of the ammonia distillation waste liquid regulating tank 1 is connected with the liquid inlet of the gypsum reaction tank 2, and the outlet of the decalcifying agent dissolving tank 3 is connected with the decalcifying agent inlet of the gypsum reaction tank 2; the slurry outlet of the gypsum reaction tank 2 is connected with the The inlet of the gypsum dehydration drying device 4 is connected, and the clear liquid outlet of the gypsum dehydration drying dev...

Embodiment 2

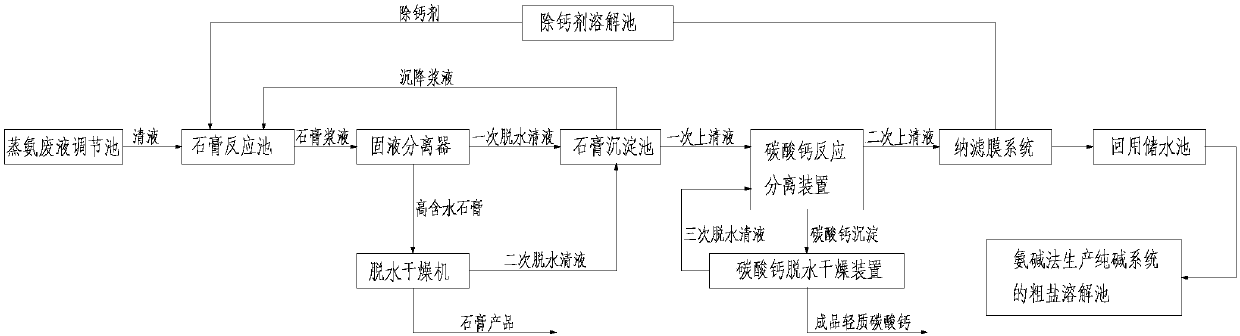

[0051] Embodiment 2: as figure 2 Shown, utilize embodiment 1 system to complete a kind of method for decalcifying agent and nanofiltration membrane combination treatment ammonia distillation waste liquid, it comprises the following steps: (1) prepare gypsum slurry; (2) make gypsum product; (3) Separating calcium carbonate; (4) making light calcium carbonate product; (5) separating and recycling by nanofiltration; wherein,

[0052] (1) Preparation of gypsum slurry: Taking the ammonia-soda method soda production plant as an example, the ammonia distillation waste liquid generated in the soda production process enters the ammonia distillation waste liquid regulating tank 1 by the feed pump, and the ammonia distillation waste liquid is in the ammonia distillation waste liquid After the homogeneous precipitation in the adjustment tank 1, the clear liquid enters the gypsum reaction tank 2, and simultaneously adds the decalcifying agent solution in the gypsum reaction tank 2; the de...

Embodiment 3

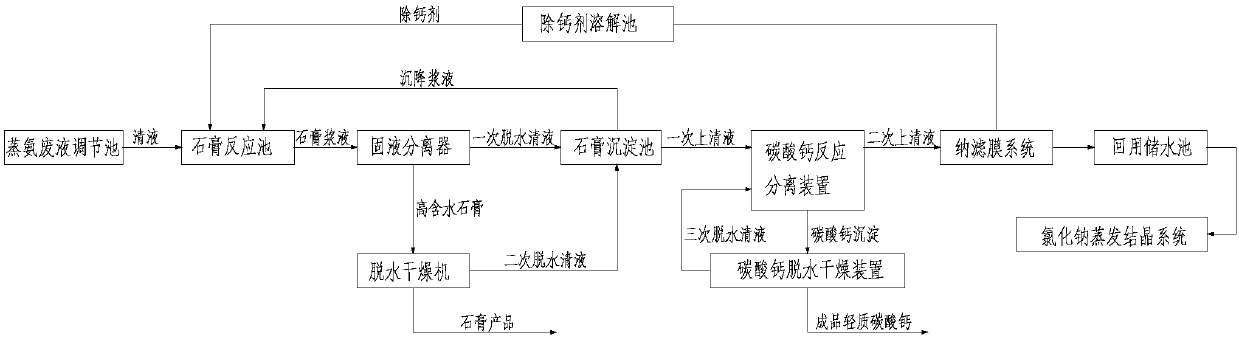

[0057] Embodiment 3: as image 3 Shown, utilize embodiment 1 system to complete a kind of method for decalcifying agent and nanofiltration membrane combination treatment ammonia distillation waste liquid, it comprises the following steps: (1) prepare gypsum slurry; (2) make gypsum product; (3) Separating calcium carbonate; (4) making light calcium carbonate product; (5) separating and recycling by nanofiltration; wherein,

[0058] (1) Preparation of gypsum slurry: Taking the ammonia-soda method soda production plant as an example, the ammonia distillation waste liquid generated in the soda production process enters the ammonia distillation waste liquid regulating tank 1 by the feed pump, and the ammonia distillation waste liquid is in the ammonia distillation waste liquid After the homogeneous precipitation in the adjustment tank 1, the clear liquid enters the gypsum reaction tank 2, and simultaneously adds the decalcifying agent solution in the gypsum reaction tank 2; the dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com