Preparation method of low-fat cake

A cake and low-fat technology, which is applied in the processing of dough, baking, baked food, etc., can solve the problems of decreased product appearance, rough taste, difficult to remove chemical reagents, etc., and is beneficial to human health, good taste, and edible The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

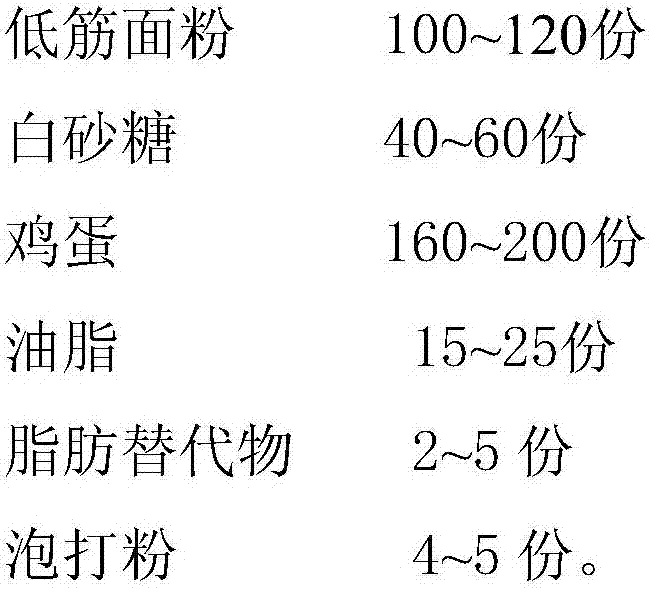

Image

Examples

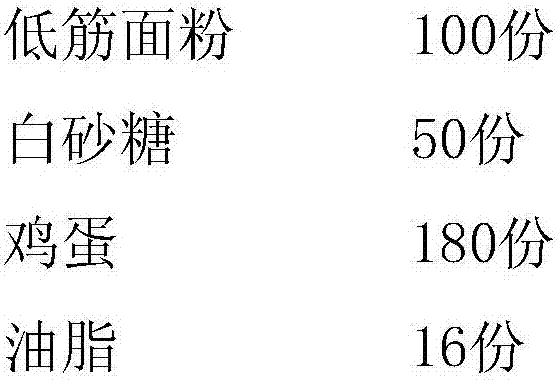

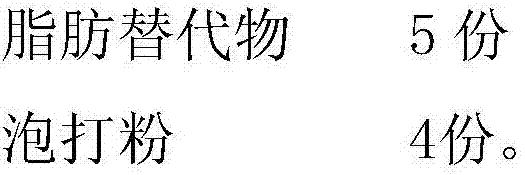

Embodiment 1

[0019] A preparation method of low-fat cake, the steps are as follows:

[0020] 1) Preparation of fat substitute: pass potato amylose through a 120-mesh sieve, add 8 times the weight of water, stir well, and stir in a boiling water bath at a low speed in one direction to fully gelatinize the starch granules until the sample appears milky white Paste, the gelatinization time is about 20min; put the fully gelatinized potato amylose paste in a high-temperature-resistant polytetrafluoroethylene container, and carry out high-temperature superheating in a high-temperature and high-pressure steam boiler of 180°C and 100kpa for 15min ;After the high-temperature superheating treatment, take out the polytetrafluoroethylene container, put it into the liquid nitrogen tank immediately, and quickly quench the temperature with liquid nitrogen for 1 minute; put the quenched gel into the ultrasonic wave for 20 minutes, and the ultrasonic power is 160W; After the ultrasound is over, put the for...

Embodiment 2

[0029] A preparation method of low-fat cake, the steps are as follows:

[0030] 1) Preparation of fat substitute: pass potato amylose through a 160-mesh sieve, add 5 times the weight of water, stir and mix well, gelatinize in a boiling water bath, and then treat at 200°C, 120kpa under high temperature and high pressure for 10 minutes, After taking it out, quickly quench and cool it with liquid nitrogen to form a gel. Ultrasonicate the gel for 15 minutes with an ultrasonic power of 180W. Quenching and cooling to form a milky white smooth surface similar to fat is the fat substitute;

[0031] 2) Prepare low-fat cake: Mix the oil and fat substitute with the whipped eggs, beat them fully in a mixer, then add white sugar, beat until the volume of the mixture fully expands and becomes milky white, then add a small amount of water, continue Whip until the foam is stable, and finally add low-gluten flour and baking powder to whip into a viscous batter, pour the batter into the mold, ...

Embodiment 3

[0035] A preparation method of low-fat cake, the steps are as follows:

[0036] 1) Preparation of fat substitute: Pass the potato amylose through a 80-mesh sieve, add 10 times the weight of water, stir and mix well, gelatinize in a boiling water bath, and then treat it at 190°C, 110kpa under high temperature and high pressure conditions for 12 minutes, After taking it out, quickly quench and cool it with liquid nitrogen to form a gel. Ultrasonicate the gel for 18 minutes with an ultrasonic power of 180W. Quenching and cooling to form a milky white smooth surface similar to fat is the fat substitute;

[0037] 2) Prepare low-fat cake: Mix the oil and fat substitute with the whipped eggs, beat them fully in a mixer, then add white sugar, beat until the volume of the mixture fully expands and becomes milky white, then add a small amount of water, continue Whip until the foam is stable, and finally add low-gluten flour and baking powder to whip into a viscous batter, pour the batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com