Unfermented dried turnip beef shrimp paste and preparation method

A technology of unfermented and dried radish, applied in the direction of food ingredients as taste improvers, food science, etc., can solve the problems of single taste, single, long operation time of shrimp paste, etc., to achieve rich nutritional value, simple process, and rich variety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

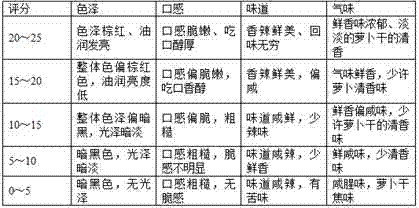

Image

Examples

Embodiment 1

[0025] A kind of unfermented radish dried beef and shrimp paste, said dried radish beef and shrimp paste is composed of the following components in parts by mass:

[0026] 100g shrimp, 100g beef, 50g dried radish, 50g sugar, 150g blended oil, 200g Pixian bean paste, 10g Zhitian pepper.

[0027] The preparation method of above-mentioned dried radish beef paste comprises the steps:

[0028] (1) Put the shrimp meat into a meat grinder and grind it into a paste; cut the beef into minced beef; chop the dried radish, add sugar and mix well; stir the Pixian bean paste into a paste, chop the chili pepper, and mix Uniform spare;

[0029] (2) Add the blended oil into the pot, heat up to 90°C, add the dried radish processed in (1) and stir-fry for 3 minutes, then add Pixian bean paste and stir-fry for 10 minutes;

[0030] (3) Add shrimp meat to the pot and stir-fry for 8 minutes, then add minced beef and stir-fry for 10 minutes; put the prepared dried radish beef and shrimp paste into ...

Embodiment 2

[0032] A kind of unfermented radish dried beef and shrimp paste, said dried radish beef and shrimp paste is composed of the following components in parts by mass:

[0033] 50g of shrimp, 50g of beef, 25g of dried radish, 25g of sugar, 75g of blended oil, 100g of Pixian bean paste, 5g of Zhitian pepper.

[0034] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0036] A kind of unfermented radish dried beef and shrimp paste, said dried radish beef and shrimp paste is composed of the following components in parts by mass:

[0037] 200g shrimp, 200g beef, 100g dried radish, 100g sugar, 300g blended oil, 400g Pixian bean paste, 20g Zhitian pepper.

[0038] The preparation method of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com