Cleaning method for reverse osmosis membrane of sea water desalination

A technology of reverse osmosis membrane and clean water, applied in chemical instruments and methods, seawater treatment, semi-permeable membrane separation, etc., can solve the problems of large maintenance workload, high maintenance cost, easy to have pipeline joints, etc., to ensure the online operation rate , the effect of shortening cleaning time and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

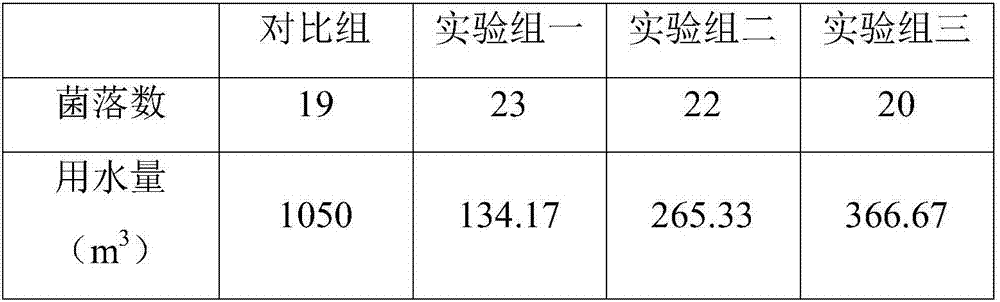

Embodiment 1

[0019] Embodiment one: a kind of cleaning method of seawater desalination reverse osmosis membrane, described cleaning method comprises on-line cleaning method and shutdown maintenance cleaning method, and the step of on-line cleaning method comprises:

[0020] (1) Configure a solution with a pH of 12 and a mass fraction of 0.03% sodium dodecylsulfonate, and perform variable flow circulation on the reverse osmosis membrane group, with a circulation flow of 500m 3 / h cycle for 15 minutes, the flow rate rises to 1000m within 15 seconds 3 / h cycle for 15 minutes, and the flow will rise to 1400m within 15 seconds 3 / h cycle for 15 minutes, then reduce the flow rate to 500m within 25 seconds 3 / h, repeat the cycle for 3 hours;

[0021] (2) flush the reverse osmosis membrane group with clear water;

[0022] (3) Configure a sulfuric acid solution with a pH of 2, and circulate and wash the reverse osmosis membrane group for 2 hours, with a flow rate of 1000m 3 / h;

[0023] (4) Ri...

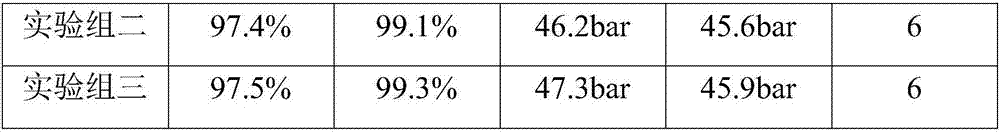

Embodiment 2

[0029] A cleaning method for reverse osmosis membranes for seawater desalination, said cleaning method comprising an online cleaning method and a shutdown maintenance cleaning method, the steps of the online cleaning method comprising:

[0030] (1) Configure a solution with a pH of 12 and a mass fraction of 0.03% sodium dodecylsulfonate, and perform variable flow circulation on the reverse osmosis membrane group, with a circulation flow of 500m 3 / h cycle for 15 minutes, the flow rate rises to 1000m within 15 seconds 3 / h cycle for 15 minutes, and the flow will rise to 1400m within 15 seconds 3 / h cycle for 15 minutes, then reduce the flow rate to 500m within 25 seconds 3 / h, repeat the cycle for 3 hours;

[0031] (2) flush the reverse osmosis membrane group with clear water;

[0032] (3) Configure a sulfuric acid solution with a pH of 2, and circulate and flush the reverse osmosis membrane group for 2 hours, with a flow rate of 1400m 3 / h;

[0033] (4) Rinse the reverse ...

Embodiment 3

[0036] A cleaning method for reverse osmosis membranes for seawater desalination, said cleaning method comprising an online cleaning method and a shutdown maintenance cleaning method, the steps of the online cleaning method comprising:

[0037] (1) Configure a solution with a pH of 12 and a mass fraction of 0.03% sodium dodecylsulfonate, and perform variable flow circulation on the reverse osmosis membrane group, with a circulation flow of 500m 3 / h cycle for 15 minutes, the flow rate rises to 1000m within 15 seconds 3 / h cycle for 15 minutes, and the flow will rise to 1400m within 15 seconds 3 / h cycle for 15 minutes, then reduce the flow rate to 500m within 25 seconds 3 / h, repeat the cycle for 3 hours;

[0038] (2) flush the reverse osmosis membrane group with clear water;

[0039] (3) Configure a sulfuric acid solution with a pH of 2, and circulate and wash the reverse osmosis membrane group for 2 hours, with a flow rate of 1200m 3 / h;

[0040] (4) Rinse the reverse o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com