A high-performance low-temperature getter and its preparation method and application

A getter and low-temperature technology, which is applied in the field of high-performance low-temperature getter and its preparation, can solve the problems of application limitation, high manufacturing cost, and long time-consuming of vacuum multi-layer heat-insulated cryogenic containers, and achieve the purpose of prolonging the life of interlayer vacuum, Improve the inhalation efficiency and shorten the time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A novel high-performance low-temperature getter, each component of the getter is composed of the following parts by weight: AlO Y ·SiO2 X Microporous powder (kaolin) 90 parts, neodymium oxide 1 part, hematite powder 30 parts, silicon oxide binder 12 parts;

[0028] Mix and granulate the raw materials; roast at 800°C for 4 hours;

[0029] Immerse the roasted φ3~φ5mm particles in a sodium hydroxide solution with a mass concentration of 15% for alkali treatment and washing; use 10% CaCl 2 solution for Ca 2+ Exchange and wash; after drying, the granular product is subjected to secondary roasting at 500°C to obtain low-temperature getter coarse material;

[0030] Put the low-temperature getter coarse material into the sealed chamber for kerosene gas-phase drying and pressure-swing passivation: evacuate the sealed chamber to 700Pa, heat the kerosene evaporator to 90°C; raise the temperature of the sealed chamber to 135°C, and perform 2 intermediate depressurizations , the...

Embodiment 2

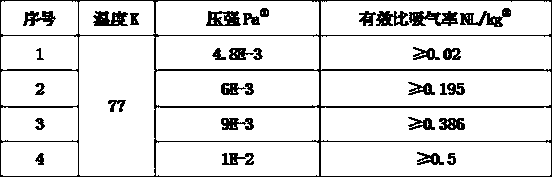

[0033] The cryogenic getter 50kg preserved in the nitrogen of embodiment 1 is packed to -20m 3 In the interlayer of the cryogenic container, the effective volume of the interlayer is 6m 3 , when the interlayer pressure at room temperature is stable at 17Pa, add liquid nitrogen to the inner container (90% full rate), and the residual gas volume in the interlayer before filling the container with cryogenic liquid is 102Pa·m 3 , after 24 hours, the interlayer pressure reached a stable level, and the low temperature pressure of the interlayer was measured to be 4.8×10 -3 Pa.

Embodiment 3

[0035] The cryogenic getter 50kg preserved in the nitrogen of embodiment 1 is packed to -31m 3 In the interlayer of the cryogenic container, the effective volume of the interlayer is 7m 3 When the interlayer pressure at room temperature is stable at 362Pa, add liquid nitrogen to the inner container (90% full rate), and the residual gas volume in the interlayer before filling with low-temperature liquid is 2534Pa·m 3 , after 46 hours, the interlayer pressure reached a stable level, and the low-temperature pressure of the interlayer was measured to be 1×10 - 2 Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com