Preparation method of phase change energy storage material

A phase-change energy storage material and energy storage material technology, which is applied in the field of preparation of phase-change energy storage materials, can solve problems such as energy waste, and achieve the effects of alleviating large energy consumption, simple preparation methods, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The phase change energy storage material provided in this embodiment is composed of n-decyl alcohol and n-undecyl alcohol in a ratio of 90:10.

[0015] Firstly weigh n-decyl alcohol and n-undecyl alcohol respectively in proportion, mix the two, then heat the above mixture in a water bath at 50°C to completely melt each component and stir for 20 minutes to make the mixture uniform, and finally cool to room temperature. into phase change energy storage materials.

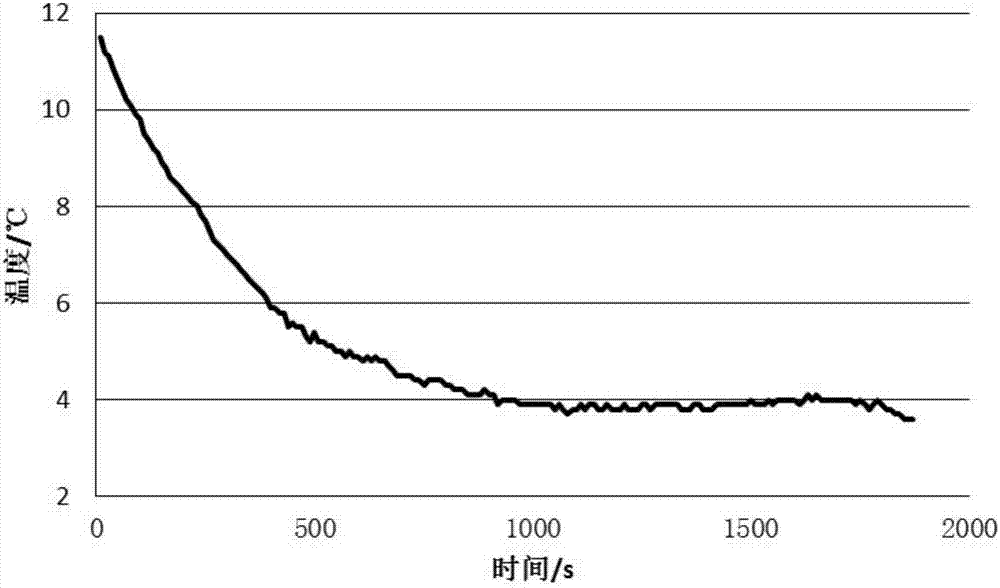

[0016] Measure the temperature change curve of phase change material with time by step cooling method, as shown in the attached figure 1 As shown, the phase change temperature of the phase change material is determined by the curve, and it can be seen that the phase change temperature is about 4°C measured by the step cooling method. The low-temperature phase-change energy storage material provided by the invention is a colorless transparent viscous liquid at room temperature. When using this material to melt...

Embodiment 2

[0018] The phase change energy storage material provided in this embodiment is composed of n-decyl alcohol and n-undecyl alcohol in a ratio of 88:12.

[0019] First weigh n-decyl alcohol and n-undecyl alcohol respectively in proportion, mix the two, then heat the above mixture in a water bath at 40°C to completely melt each component and stir for 20 minutes to make the mixture uniform, and finally cool to room temperature. into phase change energy storage materials.

Embodiment 3

[0021] The phase change energy storage material provided in this embodiment is composed of n-decyl alcohol and n-undecyl alcohol in a ratio of 92:8.

[0022] Firstly weigh n-decyl alcohol and n-undecyl alcohol respectively in proportion, mix the two, then heat the above mixture in a water bath at 60°C to completely melt each component and stir for 30 minutes to make the mixture uniform, and finally cool to room temperature. into phase change energy storage materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com