Preparation method of sodium ion battery graphene/Sb2S3/carbon composite material

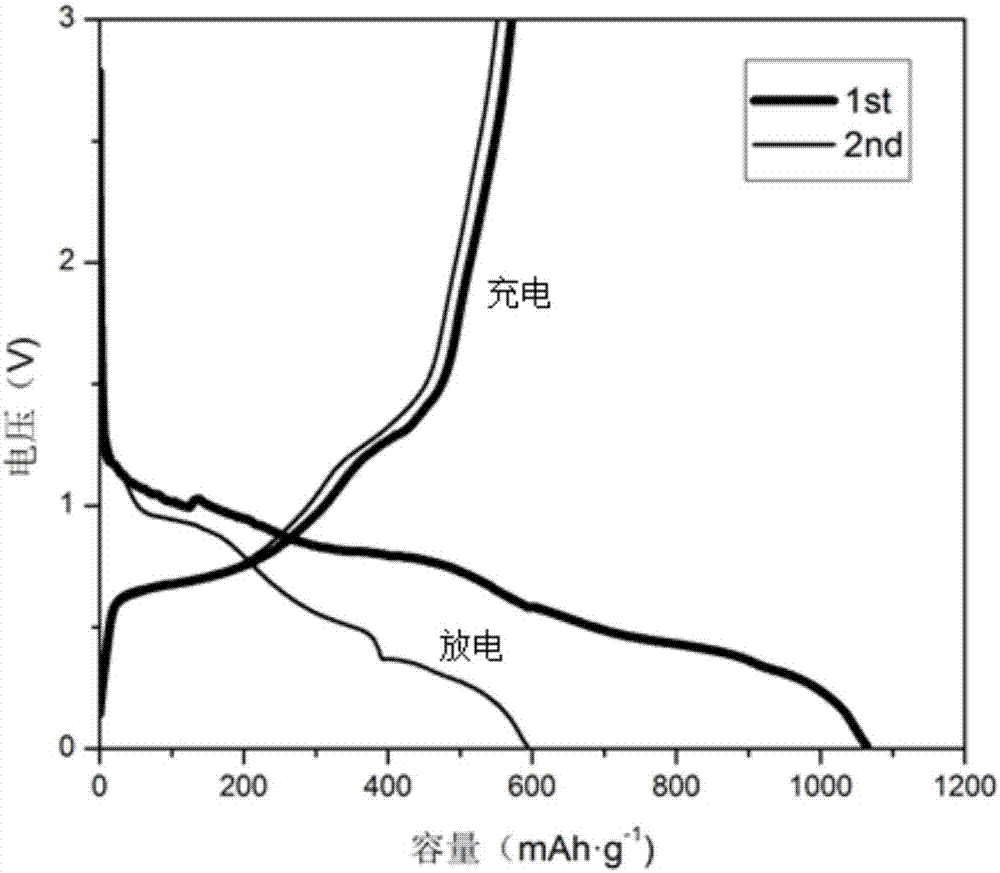

A sodium-ion battery, carbon composite material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low conductivity, easily damaged structure, large volume change, etc., and achieve high conductivity and good structural stability. Sexual, high-capacity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

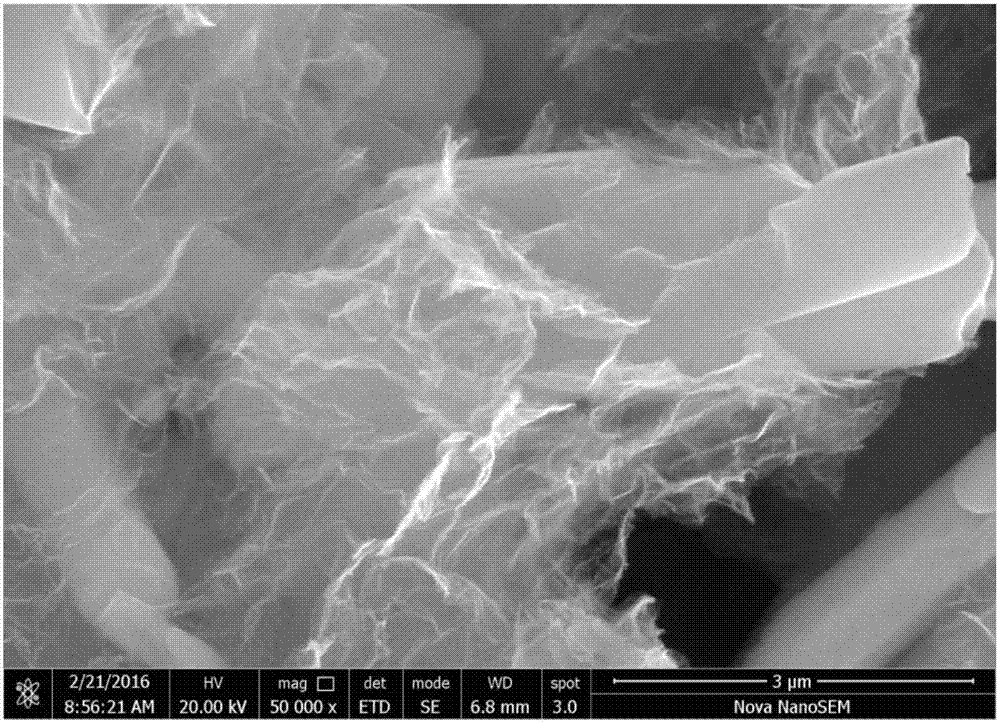

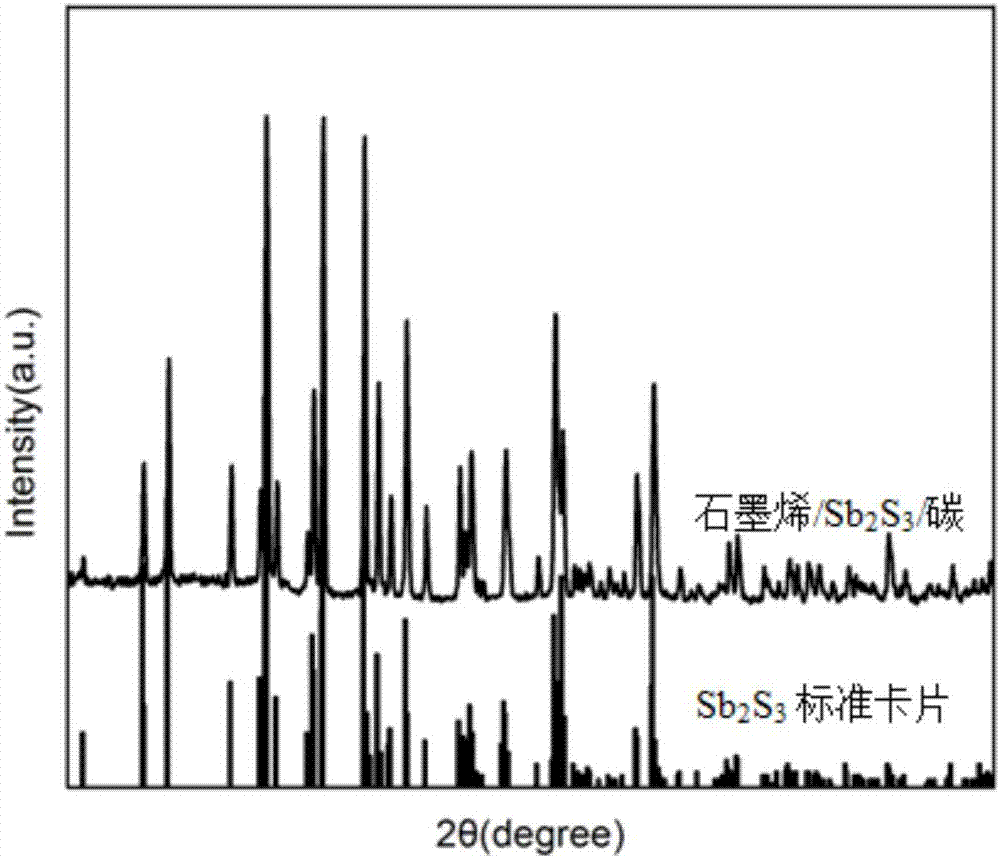

[0024] Disperse 30mg of graphite oxide in 10ml of ethylene glycol, sonicate for 3h, dissolve 0.225g of SbCl 3 Dissolve in 7ml of ethylene glycol, stir for 0.5h, add to GO dispersion, stir for 2h, add 0.115g of thioacetamide, react at 180°C for 20h, wash and dry, dissolve the obtained solid in 12ml of ethylene glycol In the middle, ultrasonic for 3 hours, add 0.1g of glucose, stir for 1 hour, react at 180°C for 10 hours to obtain the composite material, wash and dry, place in a tube furnace and heat up under the protection of an inert gas. The heating rate is 5°C / min, and the heat treatment temperature at 500°C, the holding time is 5h, and the graphene / Sb 2 S 3 / carbon composite.

Embodiment 2

[0026] Disperse 30mg of graphite oxide in 10ml of ethylene glycol, sonicate for 3h, dissolve 0.225g of SbCl 3 Dissolve in 7ml of ethylene glycol, stir for 0.5h, add to GO dispersion, stir for 2h, add 0.115g of thioacetamide, react at 180°C for 20h, wash and dry, dissolve the obtained solid in 12ml of ethylene glycol In the middle, ultrasonic for 3 hours, add 0.2g glucose, stir for 1 hour, react at 180°C for 10 hours to obtain the composite material, wash and dry, place in a tube furnace and heat up under the protection of inert gas, the heating rate is 5°C / min, the heat treatment temperature at 500°C, the holding time is 5h, and the graphene / Sb 2 S 3 / carbon composite.

Embodiment 3

[0028] Disperse 40mg of graphite oxide in 10ml of ethylene glycol, sonicate for 3h, dissolve 0.225g of SbCl 3 Dissolve in 7ml of ethylene glycol, stir for 0.5h, add to GO dispersion, stir for 2h, add 0.115g of thiourea, react at 180°C for 20h, wash and dry, dissolve the obtained solid in 12ml of ethylene glycol, Sonicate for 3 hours, add 0.2g glucose, stir for 1 hour, react at 180°C for 10 hours to obtain a composite material, wash and dry, place in a tube furnace and heat up under the protection of an inert gas. The heating rate is 5°C / min, and the heat treatment temperature is 500°C. ℃, the holding time is 5h, and the graphene / Sb 2 S 3 / carbon composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com