Sulfurated modified Fe-Cu bimetallic material, preparation method and method for removing chromium-containing wastewater

A bimetallic and modified technology, used in metal processing equipment, chemical instruments and methods, water pollutants, etc., can solve the problems of narrow pH range, low activity of micron materials, complex preparation of nanomaterials and difficult to store.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Technical scheme of the present invention is as follows:

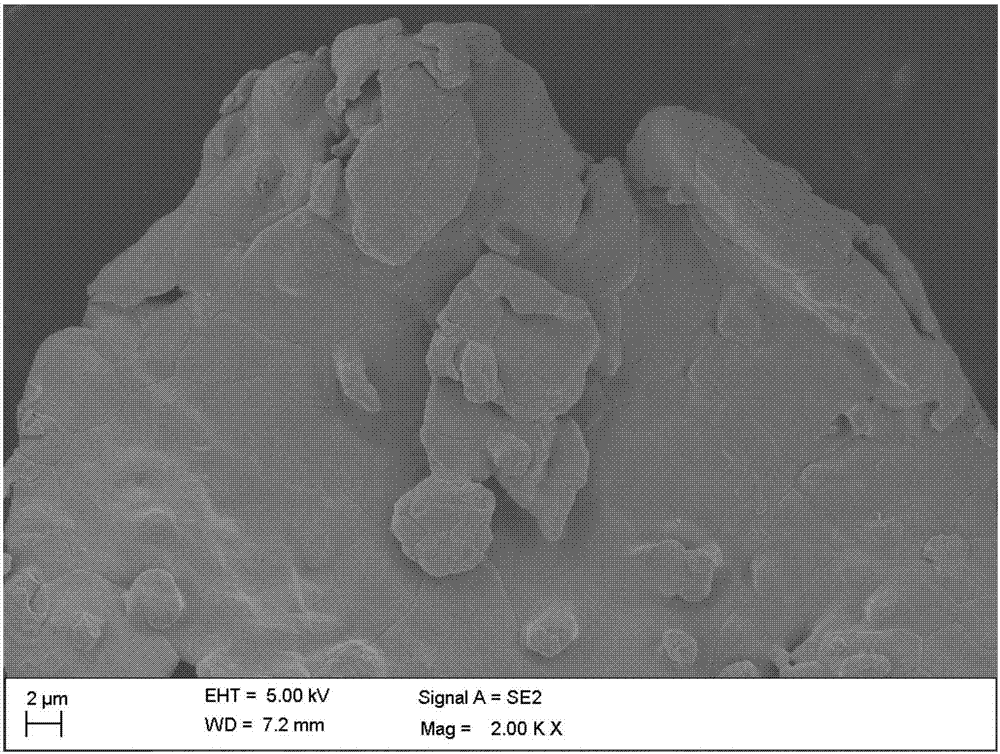

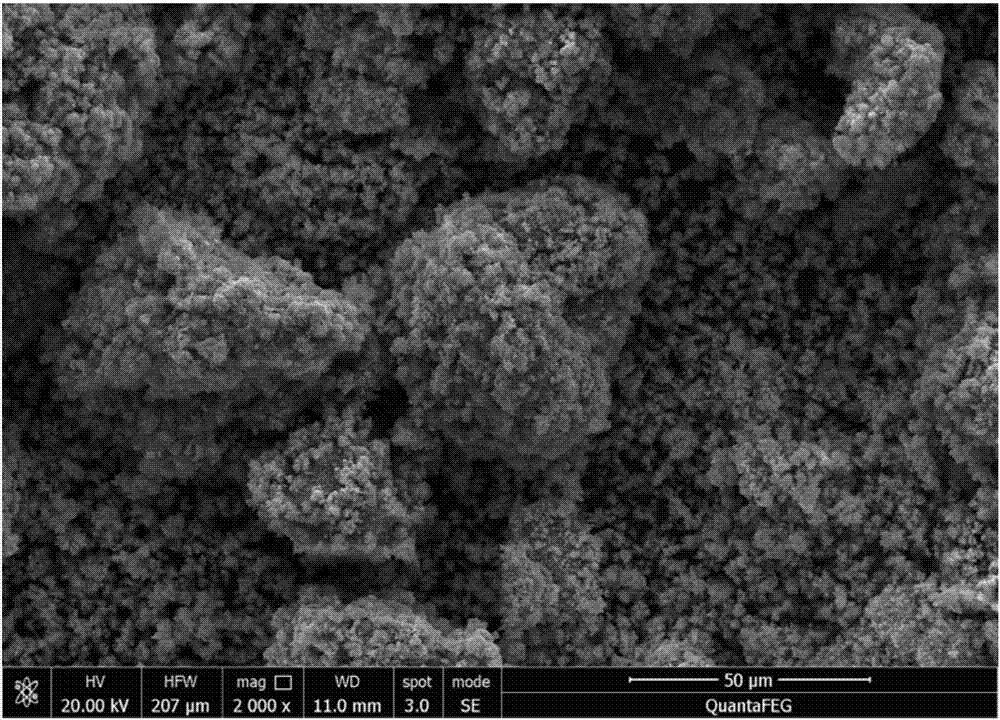

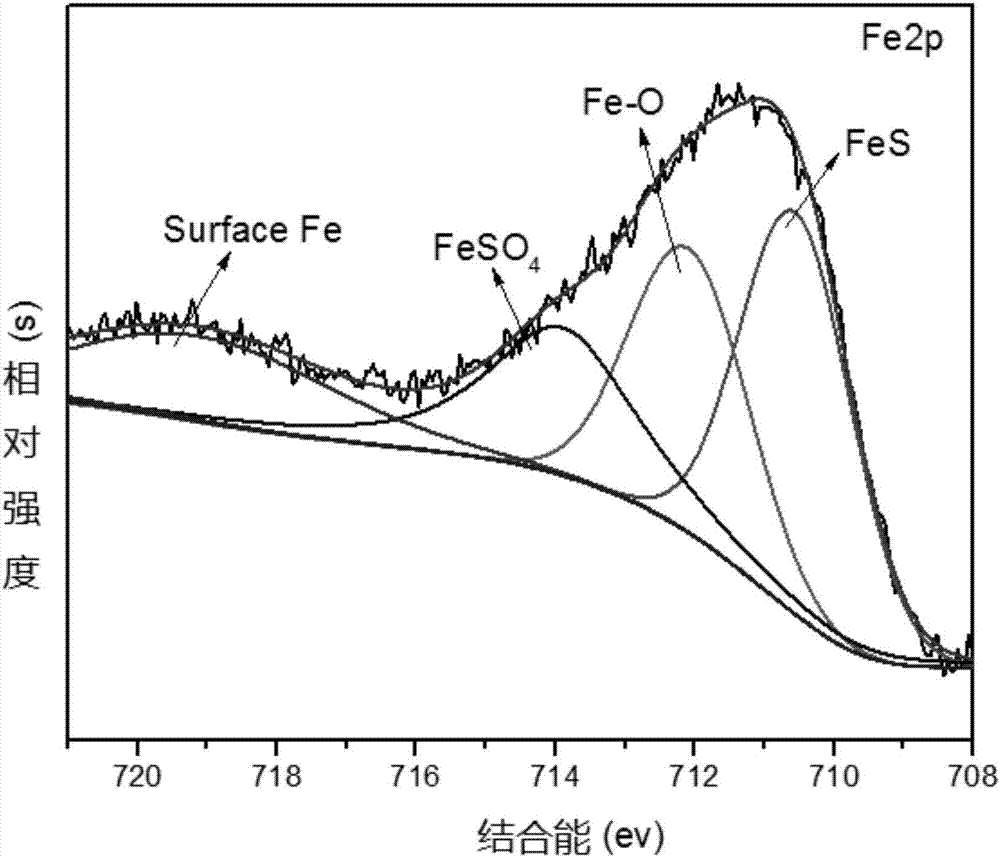

[0008] A vulcanized modified Fe-Cu bimetallic material, in which the sulfur-iron molar ratio is (0.05-0.06):1, and the iron-copper mass ratio is 10:(0.1-4).

[0009] According to the present invention, preferably, the sulfur-iron molar ratio in the sulfur-modified Fe-Cu bimetallic material is 0.056:1, and the iron-copper mass ratio is 10:0.5.

[0010] According to the present invention, the preparation method of the above-mentioned vulcanized modified Fe-Cu bimetallic material comprises:

[0011] A step of reacting zero-valent iron with soluble sulfide salts in a buffer solution in an acidic environment to obtain sulfurized modified zero-valent iron;

[0012] And, the step of obtaining sulfide-modified Fe-Cu bimetallic material through substitution reaction of sulfide-modified zero-valent iron and divalent copper salt.

[0013] According to the preparation method of the present invention, preferably, the buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com