Modifier for rare earth tailing sand remediation and treatment method for rare earth tailing sand

A technology of tailings sand and improver, which is applied in chemical instruments and methods, botanical equipment and methods, applications, etc., and can solve problems such as short duration, high cost of polymer compounds, and hazards to plants and microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention has no special limitation on the preparation method of the improving agent described in the above technical solution, and the technical solution prepared by a composition well known to those skilled in the art can be used, specifically: the sepiolite, animal excrement, humic acid Mixed with biochar to obtain a modifier for repairing rare earth tailings sand. In the present invention, the mixture is preferably stored in bags, preferably 50 kg per bag, so as to facilitate the metering during administration.

[0040] The present invention also provides a treatment method for rare earth tailings, comprising the following steps:

[0041] (1) applying the improving agent described in the above-mentioned technical scheme to rare earth tailings;

[0042] (2) Planting drought-tolerant herbaceous plants on the rare earth tailings sand after applying the modifier.

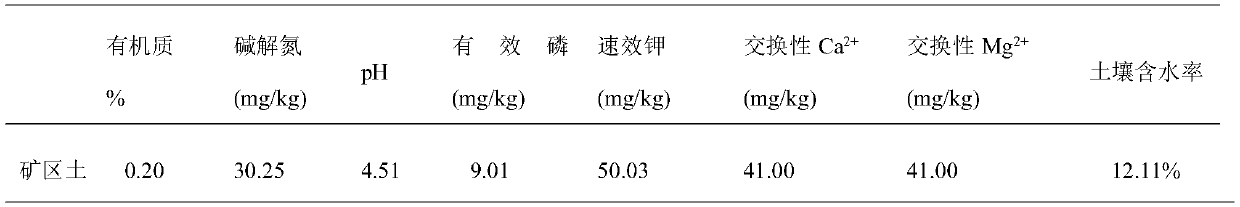

[0043] In an embodiment of the present invention, the mass percentage of organic matter in t...

Embodiment 1

[0057] The preparation of the improver: 4 parts of sepiolite, 3 parts of chicken manure, 2 parts of humic acid and 2 parts of biochar.

[0058] Among them, the pH value of sepiolite is 10.5, the organic matter is 0.95%, the CEC is 18cmol / kg, the pore diameter is 1.35nm, and the specific surface area is as high as 900m 2 / g; the component is Mg 3 Si 2 (OH) 4 o 5 9%, Si 3 o 6 ·H 2 O 8%, CaMgSi 2 o 6 17% and CaCO 3 66%;

[0059] The pH value of chicken manure is 6.23, and the organic matter content is 63.2g·kg -1 , N, P, K are 16g·kg respectively -1 , 7.3g·kg -1 、6.2g·kg -1 ;

[0060] Humic acid has a pH value of 4.0, organic matter (dry basis) 65%, humic acid (dry basis) 40%, CEC≧250meq / 100g, particle size 5mm.

[0061] Biochar particle size is 2mm, specific surface area is 50.22m 2 / g, pH value is 7. Biochar components: C 75.22%, H2.36%, N 1.01%, O 17.45%, total potassium 11.01% and total phosphorus 2.64%, of which the crude ash is 2.67wt%.

[0062] The simu...

Embodiment 2

[0066] The preparation of the improver: 4 parts of sepiolite, 3 parts of chicken manure, 2 parts of humic acid and 2 parts of biochar.

[0067] Among them, the pH value of sepiolite is 9.8, the organic matter is 0.83%, the CEC is 15cmol / kg, the pore diameter is 1.30nm, and the specific surface area is as high as 900m 2 / g; the component is Mg 3 Si 2 (OH) 4 o 5 8%, Si 3 o 6 ·H 2 O 10%, CaMgSi 2 o 6 15% and CaCO 3 67%;

[0068] The pH value of chicken manure is 6.5, and the organic matter content is 65.8g·kg -1 , N, P, K are 20g·kg respectively -1 , 8.3g·kg -1 , 11.5g·kg -1 ;

[0069] Humic acid has a pH value of 5.5, organic matter (on a dry basis) 73%, dry basis humic acid is 40% of the mass of wet humic acid, CEC≧300meq / 100g, and a particle size of 4.5mm.

[0070] The particle size of biochar is 2.8mm, and the specific surface area is 60.30m 2 / g, pH value is 8.0. Biochar components: C 57.23%, H 2.36%, N 1.9%, O 17%, total potassium 10.67% and total phospho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com