Laser phase transition hardening method and bionic camshaft with hard phase prepared by method

A technology of phase transformation strengthening and hard phase, which is applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of inevitable oxidation, decarburization, poor wear resistance, easy cracks, etc., to achieve easy automatic control, improve durability Abrasiveness and small deformation of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

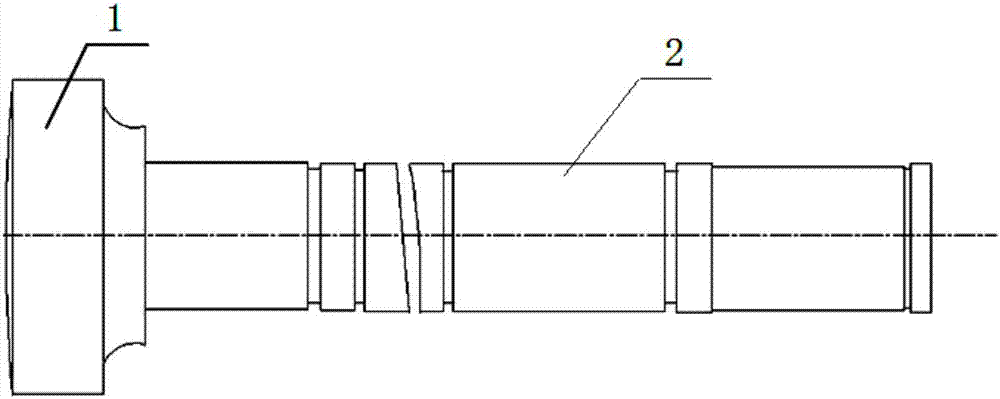

[0035] The brake camshaft of this embodiment is suitable for a tractor that tows or pushes a trailer. The laser strengthening treatment method of the brake camshaft is as follows:

[0036] Step 1: Treat the surface of the workpiece by mechanical processing to meet the use requirements of the surface of the workpiece.

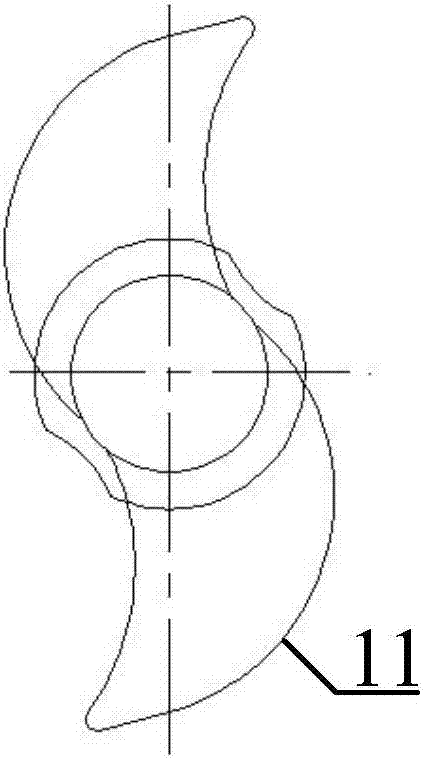

[0037] Step 2. For a light tractor, select the bionic model of the corresponding brake camshaft cam, as shown in Table 1.

[0038] Table 1 The bionic model suitable for light tractor brake camshaft cam

[0039]

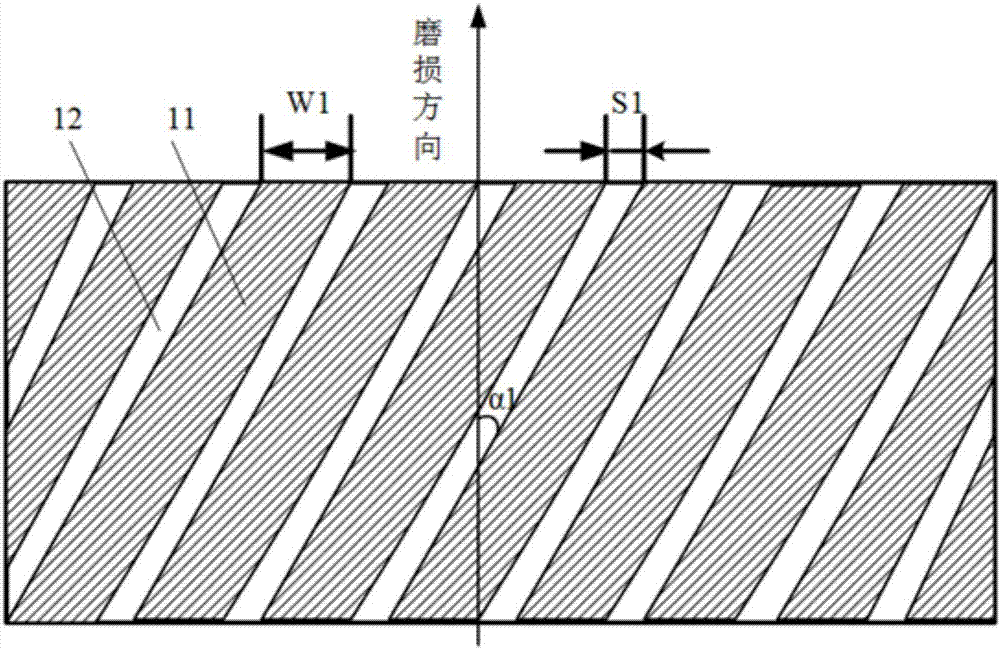

[0040] Step 3. According to the bionic model ① and E=P / DV=17.78J / mm 2 For the energy density, the processing parameters are as follows: the circular spot size is D=Φ3mm, the laser power is P=800W, and the scanning speed is V=15mm / s.

[0041] Step 4: Scan the laser beam along the set path on the surface of the workpiece to form a hard phase unit body with stripe-shaped structures uniformly distributed and grain refinement on the surface.

[0042] ...

Embodiment 2

[0044] The brake camshaft of this embodiment is suitable for a tractor that tows or pushes a trailer. The laser strengthening treatment method of the brake camshaft is as follows:

[0045] Step 1: Treat the surface of the workpiece by mechanical processing to meet the use requirements of the surface of the workpiece.

[0046] Step 2. For a medium-sized tractor, select the bionic model of the corresponding brake camshaft cam, as shown in Table 2.

[0047] Table 2 The bionic model of the brake camshaft cam suitable for medium-sized tractors

[0048]

[0049] Step 3. According to the bionic model ② and E=P / DV=18.75J / mm 2 The energy density, the processing parameters adopted are as follows: the circular spot size is D=Φ4mm, the power is P=900W, and the scanning speed is V=12mm / s.

[0050] Step 4: Scan the laser beam along the set path on the surface of the workpiece to form a strip-shaped hard phase unit with uniform distribution and fine grains on the surface.

[0051] The...

Embodiment 3

[0053] The brake camshaft of this embodiment is suitable for a tractor that tows or pushes a trailer. The laser strengthening treatment method of the brake camshaft is as follows:

[0054] Step 1: Treat the surface of the workpiece by mechanical processing to meet the use requirements of the surface of the workpiece.

[0055] Step 2. For heavy-duty tractors, select the bionic model corresponding to the brake camshaft cam, as shown in Table 3.

[0056] Table 3 The bionic model suitable for heavy-duty tractor brake camshaft cams

[0057]

[0058] Step 3. According to the bionic model ③ and E=P / DV=20.00J / mm 2 The energy density, the processing parameters adopted are as follows: the circular spot size is D=Φ5mm, the power is P=1000W, and the scanning speed is V=10mm / s.

[0059] Step 4: Scan the laser beam along the set path on the surface of the workpiece to form a strip-shaped hard phase unit with uniform distribution and fine grains on the surface.

[0060] The above meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com