O/W type palm oil based special mold release agent for baking and preparation method thereof

A release agent, palm olein technology, applied in the direction of dough anti-sticking, etc., can solve the problems of poor release effect, easy environmental pollution, residual carbon dirt, etc., and achieve the effect of convenient application, high concentration, and low viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of O / W type palm oil-based special release agent for baking, the steps comprise:

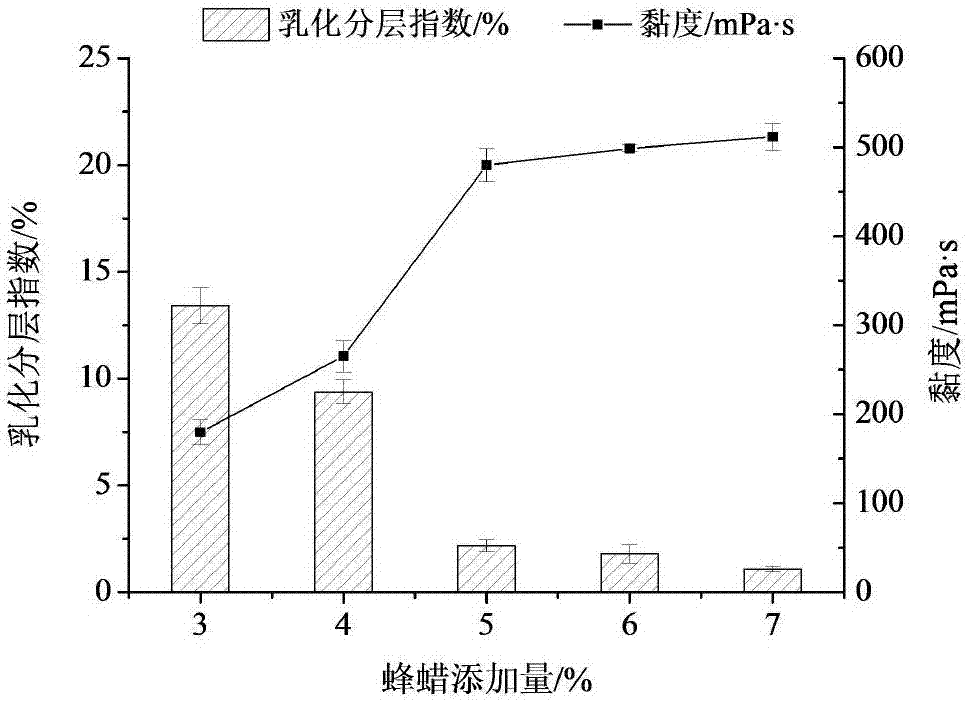

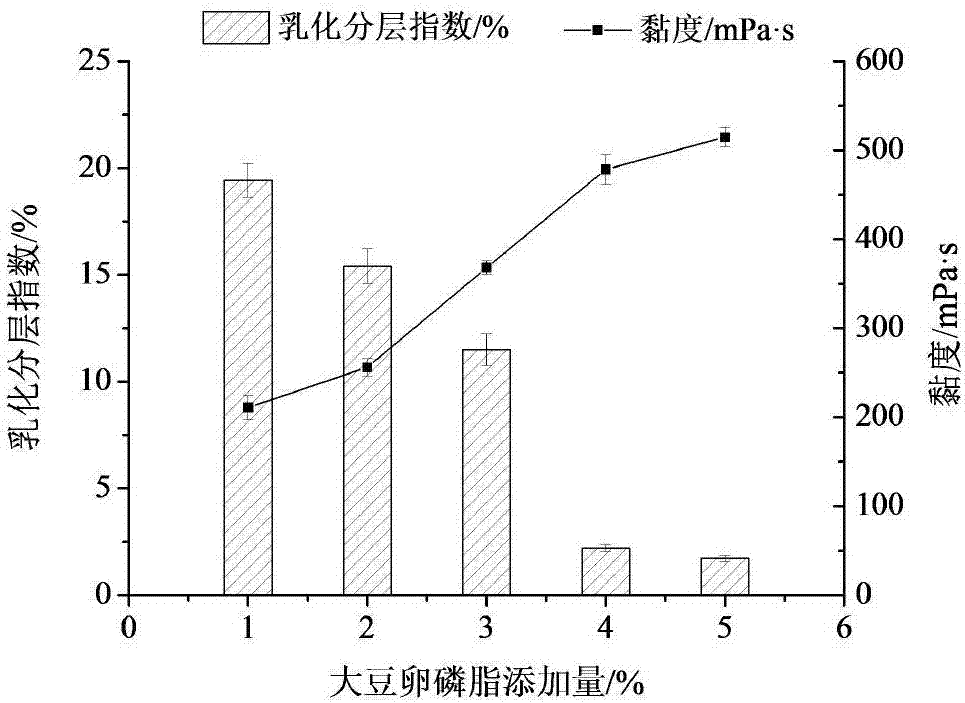

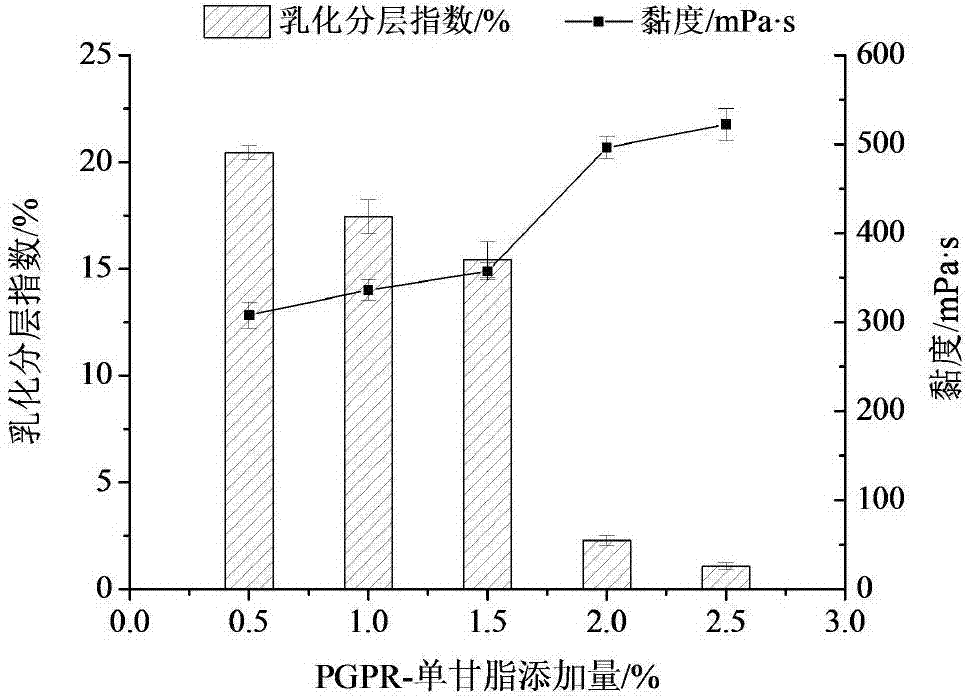

[0030] (1) Add 60g of palm olein and 4% of the quality of palm olein to a glass bottle with a bottom diameter of 60 mm, stir and heat to 85°C until the beeswax is completely dissolved, then add 2% of the mass of palm olein soybean lecithin, 1.5% polyglycerol castor oil-monoglyceride (the weight ratio of polyglycerol castor oil and monoglyceride is 9:1), heating, fully stirring, mixing until oil Dissolve the soluble emulsifier completely and keep it warm for later use to obtain the release agent oil phase A;

[0031] (2) Add pure water (the weight here is 140g) into the triangular flask according to the oil-water ratio 2:8, and the composite stabilizer (the weight ratio of its xanthan gum, guar gum and carrageenan) of 0.3% of the quality of water The ratio is 1:2.5:1) Add water to heat, stir and mix well until the water-soluble emulsifier is completely dissolv...

Embodiment 2

[0035] A preparation method of an O / W type palm oil-based baking special release agent, the steps comprising:

[0036] (1) Add 60g of palm olein and 5% beeswax of palm olein into a glass bottle with a bottom diameter of 60mm, stir and heat to 90°C until the beeswax is completely dissolved, and then add 4% of palm olein of soybeans Lecithin, 2% polyglycerol ricinoleate-monoglyceride (the weight ratio of polyglycerol ricinoleate and monoglyceride is 8:2), heating, fully stirring, mixing until oil-soluble emulsification Dissolve the agent completely, keep it warm for later use, and obtain the oil phase A of the release agent;

[0037] (2) Add pure water (the weight here is 140g) in the triangular flask according to the oil-water ratio 3:7, and the composite stabilizer (the weight ratio of its xanthan gum, guar gum and carrageenan) of 0.4% of the water quality The ratio is 1:2.5:1) Add water to heat, stir and mix well until the water-soluble emulsifier is completely dissolved, ke...

Embodiment 3

[0041] A preparation method of an O / W type palm oil-based baking special release agent, the steps comprising:

[0042] (1) Add 60g of palm olein and 7% of the quality of palm olein into a glass bottle with a bottom diameter of 60 mm, stir and heat to 95°C until the beeswax is completely dissolved, then add 1% of the mass of palm olein soybean lecithin, 3% polyglycerol castor oil-monoglyceride (the weight ratio of polyglycerol castor oil and monoglyceride is 7:3), heating, fully stirring, mixing until oil Dissolve the soluble emulsifier completely and keep it warm for later use to obtain the release agent oil phase A;

[0043](2) Add pure water (the weight here is 140g) into the triangular flask according to the ratio of oil to water 4:6, add 0.5% composite stabilizer (the weight of its xanthan gum, guar gum and carrageenan) of the pure water quality The ratio is 1:2.5:1) Add water to heat, stir and mix well until the water-soluble emulsifier is completely dissolved, keep warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com