A kind of preparation method of highly air-permeable burn and scald dressing

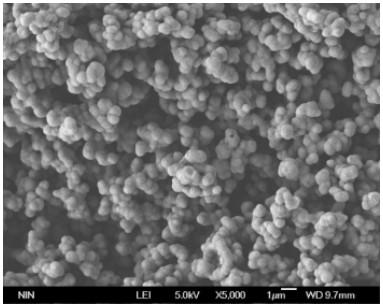

A gas-permeable, burn-and-scald technology, applied in bandages, medical science, etc., can solve problems such as low adhesion and no ability to promote wound healing, and achieve high moisture retention, optimized pore-forming effect, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Preparation of dressing for burns and scalds

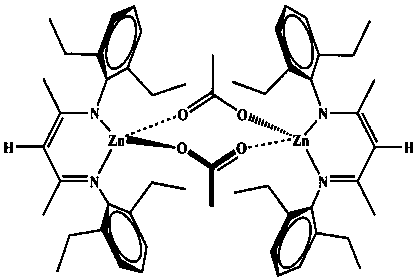

[0024] Step 1: Dissolve water-soluble protein HLC in 10 mL distilled water to obtain an HLC solution with a concentration of 200 mg / mL, and add 2% cross-linking agent β-diimine zinc complex and 1, 2, 7, 8 - Diepoxyoctane each 2 mL, then add 2 mL of 10 mg / mL KCl solution, mix well, and adjust the pH of the solution to 4.5 with dilute hydrochloric acid;

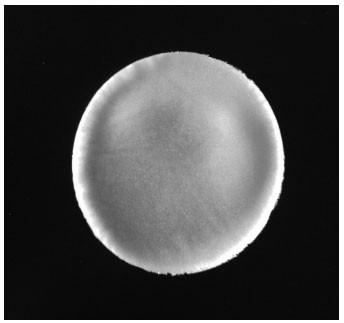

[0025] Step 2: Divide the mixed solution in step 1 into molds, keep at 50°C for 2 hours, then transfer to a high-pressure steam sterilizer and keep at 121°C for 20 minutes to obtain the primary gel product;

[0026] Step 3: soak and wash the primary gel in step 2 with distilled water for 5 days, and change the washing water every 6 hours to remove salt and residual crosslinking agent; transfer the washed primary gel to a high-pressure steam sterilizer Continue to keep at 121°C for 2 h, then soak and wash with distilled water again for 2 days, control the total amo...

Embodiment 2

[0032] Example 2 Preparation of dressing for burns and scalds

[0033]Step 1: Dissolve the water-soluble protein BSA in 10 mL distilled water to obtain a BSA solution with a concentration of 100 mg / mL, and add 2% cross-linking agent β-diimine zinc complex and 1, 2, 7, 8 - Diepoxyoctane 1 mL each, then add 2 mL of 10 mg / mL NaCl solution, mix well, and adjust the pH of the solution to 3.5 with dilute hydrochloric acid;

[0034] Step 2: Divide the mixed solution in step 1 into molds, keep at 60°C for 2 hours, then transfer to a high-pressure steam sterilizer and keep at 121°C for 20 minutes to obtain the primary gel product;

[0035] Step 3: soak and wash the primary gel in step 2 with distilled water for 5 days, change the washing water every 6 hours to remove salt and residual cross-linking agent; transfer the washed primary gel to an autoclave to continue Keep at 121°C for 2 h, then soak and wash with distilled water for 2 days again, control the total amount of residual cros...

Embodiment 3

[0038] Example 3 Preparation of dressing for burns and scalds

[0039] Step 1: Dissolve α-lactalbumin in 10 mL distilled water to obtain a solution with a concentration of 100 mg / mL, add 1% cross-linking agent β-diimine zinc complex and 1, 2, 7, 8 - Diepoxyoctane each 2 mL, then add 50 mg / mL NaNO 3 Solution 2mL, mix well, and adjust the pH of the solution to 5.5 with dilute hydrochloric acid;

[0040] Step 2: Divide the mixed solution in step 1 into molds, keep at 50°C for 2 hours, then transfer to a high-pressure steam sterilizer and keep at 121°C for 20 minutes to obtain the primary gel product;

[0041] Step 3: soak and wash the primary gel in step 2 with distilled water for 5 days, change the washing water every 6 hours to remove salt and residual cross-linking agent; transfer the washed primary gel to an autoclave to continue Keep at 121°C for 2 h, then soak and wash with distilled water for 2 days again, control the total amount of residual cross-linking agent to be le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com