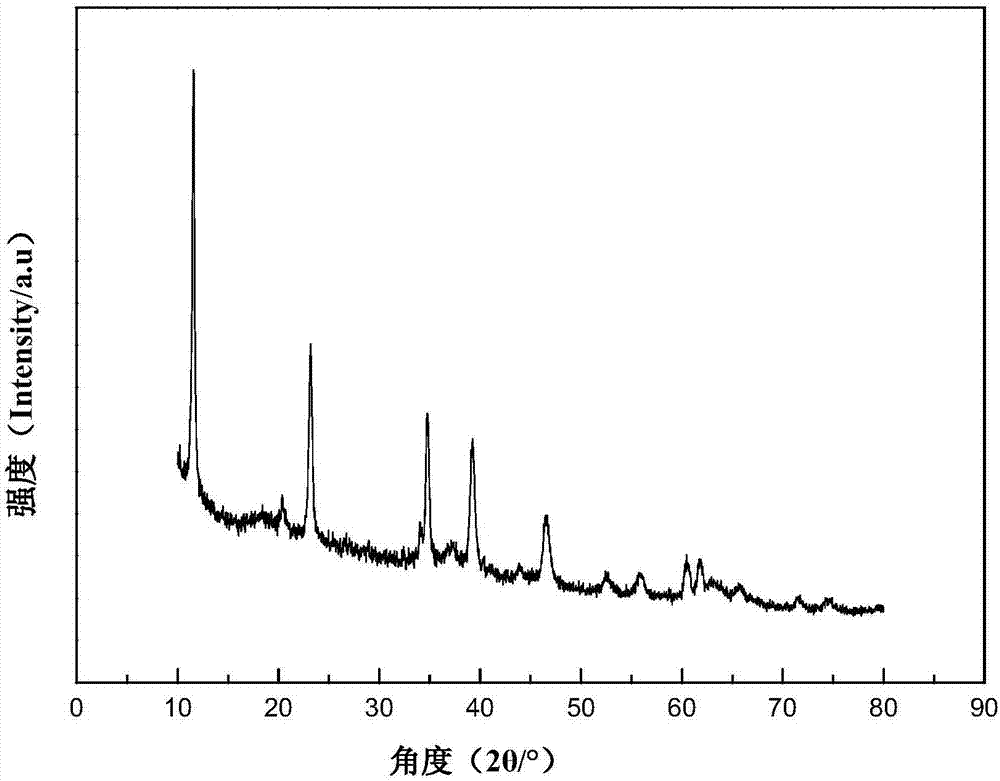

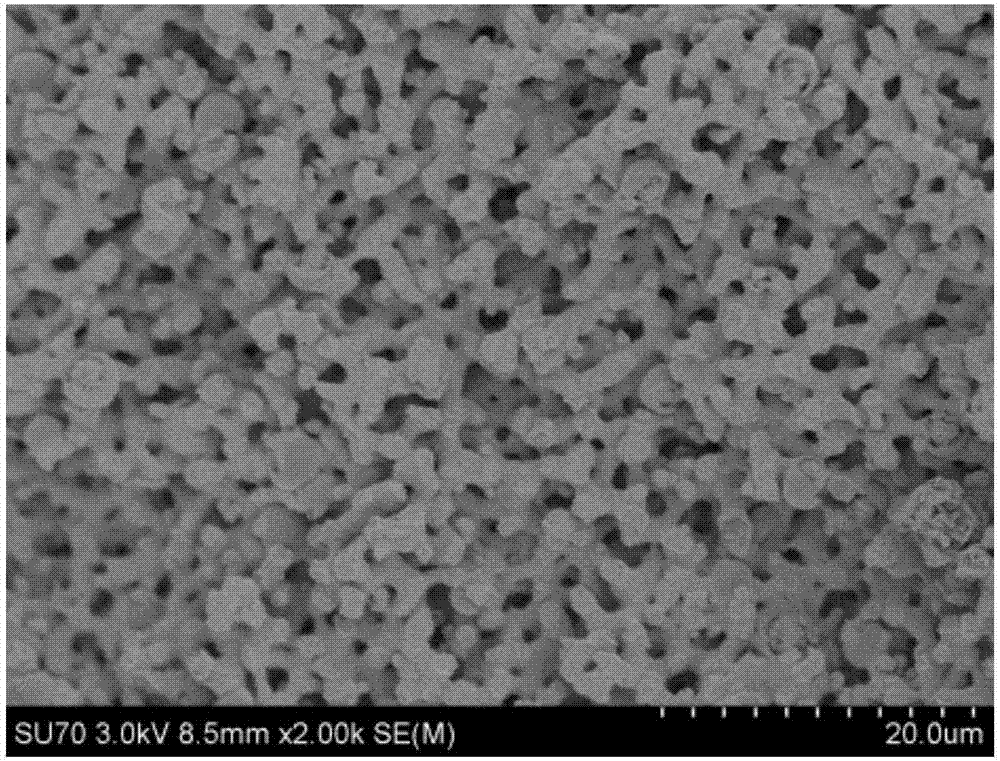

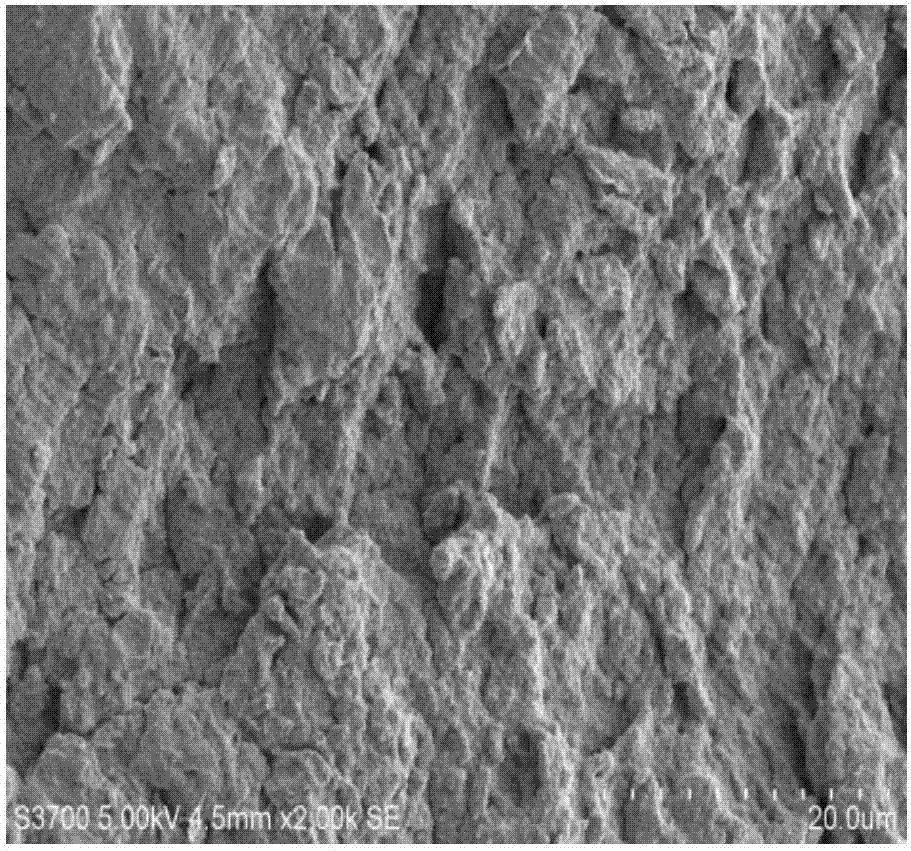

Preparation method for layered zinc-aluminum double hydroxide porous block used for dye adsorption

A double hydroxide and dye adsorption technology, which is applied in the preparation of alumina/hydroxide, zinc oxide/zinc hydroxide, aluminum compounds, etc., to achieve the effects of low cost, high adsorption capacity, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1. A method for preparing a layered zinc-aluminum double hydroxide porous block. First, the main raw materials were prepared in the following proportions: 0.005 mol of anhydrous zinc chloride was used as the zinc source, and 0.01 mol of aluminum chloride hexahydrate was used as the zinc source. It is aluminum source, 0.9g urea is anionic carbonic acid source, 0.35g polyethylene oxide (PEO, the average molecular weight is 1×10 6 ) is a phase separation inducer and 3.2 ml of 1,2-propylene oxide is a gel accelerator; then carry out the following steps in sequence:

[0035] 1), at room temperature, polyethylene oxide is dissolved in solvent (being made up of deionized water of 3ml and dehydrated alcohol of 2ml) and stirring reaction 15min, obtains homogeneous solution;

[0036] 2), adding anhydrous zinc chloride, aluminum chloride hexahydrate and urea to the homogeneous solution obtained in step 1) respectively, stirring and reacting at 90 ° C for 12 h, and then coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com