Shielding assembly structure with high-efficiency shielding properties

A technology of shielding performance and component structure, applied in the field of shielding component structure with high-efficiency shielding performance, can solve the problems of unfavorable long-life use of the reactor vessel, increased radiation of the reactor vessel, difficult industrial processing, etc., and achieves good protection effect, Improve reliability and security, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

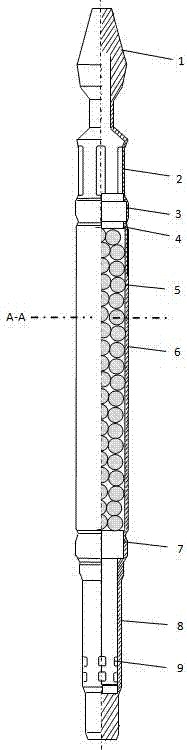

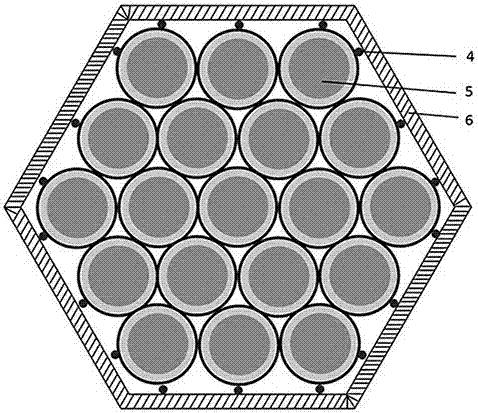

Embodiment 1

[0032] Such as Figure 6 As shown, 19 shielding element balls with a diameter of R are placed in an equilateral triangle on each layer, and the shielding element balls on adjacent layers are arranged in the same way. Stack upwards in turn, and stack the H / R layer shielding element balls together. At the same time, the vibration of the shielding element ball under the action of the coolant is limited through the restraining effect of the support rods and the upper and lower grid plates. The implementation of this shielding component has been numerically simulated by simulation software. At the original height of the rod cavity and end plug of the shielding component, the neutron flux reaching the reactor vessel is reduced by 21%, which improves the overall shielding effect of the shielding component.

Embodiment 2

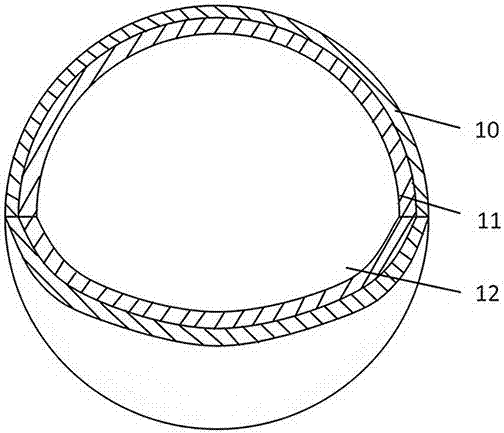

[0034] Such as Figure 7 shown. On the basis of Embodiment 1, the diameter is R 1 , R 2 Two sizes of shielding element balls, the diameter of the smaller shielding element ball . The shielding element balls are staggered up and down, so that the small shielding element balls are in the gap between the large shielding element balls of the adjacent layer, and are in contact with the large shielding element balls of the upper and lower layers. Due to the restraint effect of the support rods and the upper and lower grid plates, the vibration of the large shielding element ball under the action of the coolant is very small. At the same time, the large shielding balls in the adjacent layers also have constraints on the small shielding balls. Compared with the first solution, the overall shielding performance of the shielding component is improved by about 12%. However, since the flow channel of the coolant becomes smaller, the thermal stress of the shielding component also in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com