Aluminum electrolysis flue gas desulfurization device and desulfurization method

A desulfurization device, electrolytic aluminum technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of not having the conditions for desulfurization of seawater, and achieve the effects of broad market application prospects, short process flow, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

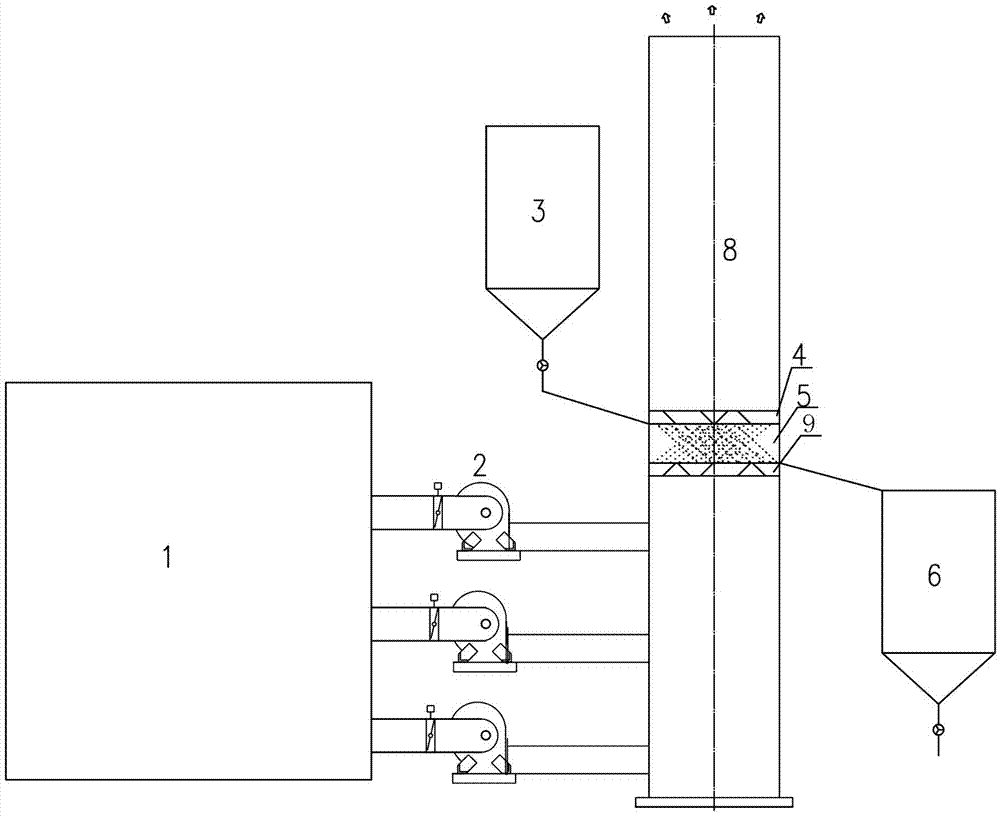

[0029] Such as figure 1 As shown in , an electrolytic aluminum flue gas desulfurization device, the flue gas from the electrolytic aluminum flue gas dry process system 1 is connected to the fluidized boiling box 5, and the flue gas from the fluidized boiling box 5 is discharged through the chimney 8 . The flue gas from the electrolytic aluminum flue gas dry process system is sent to the fluidized boiling box through the main induced draft fan 2, and the fluidized boiling box 5 is provided with an adsorbent. The fluidized boiling box 5 is arranged in the middle of the chimney 8, the main induced draft fan 2 sends the flue gas from the electrolytic aluminum flue gas dry process system 1 to the lower part of the chimney 8, and the fluidized boiling box 5 feed inlet is set at The upper part communicates with the fresh feed bin 3 , and the outlet of the fluidized boiling box 5 is located in the lower part and communicates with the reaction feed bin 6 . The bottom of the fluidized...

Embodiment 2

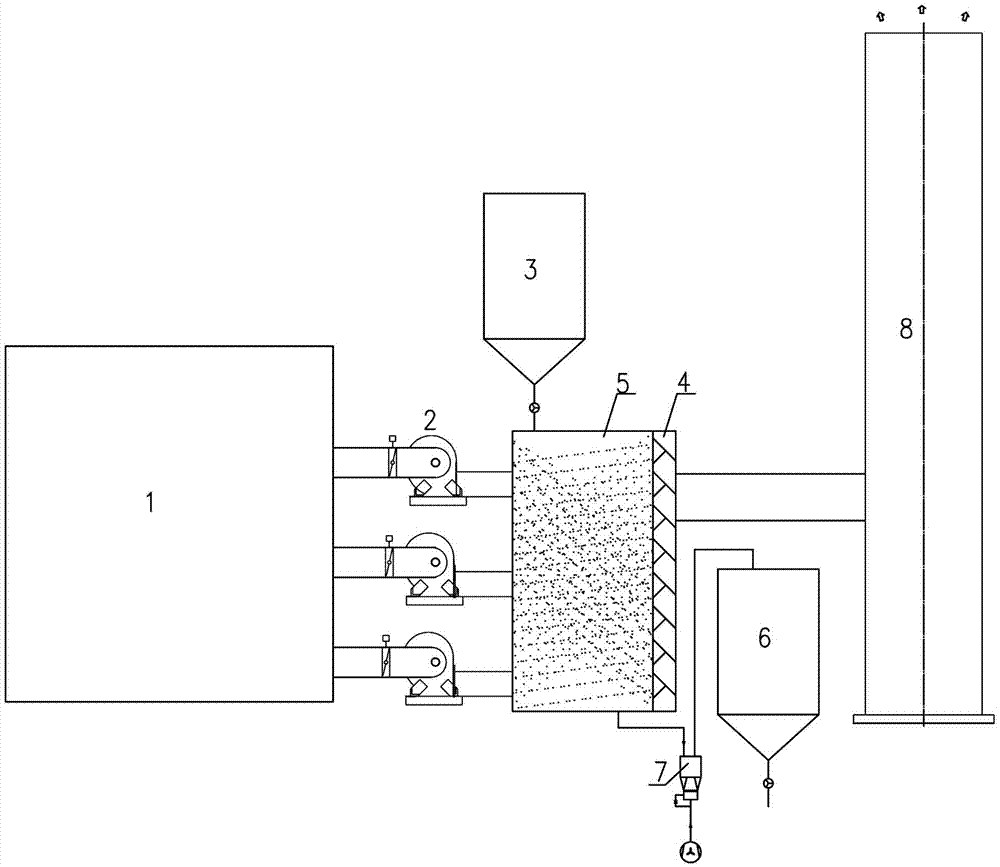

[0032] The fluidized boiling tank in Example 1 is arranged between the main induced draft fan and the chimney. The smoke inlet of the fluidized boiling box is connected with the main induced draft fan, and the smoke outlet of the fluidized boiling box is connected with the chimney; The outlet of the boiling box is located at the bottom and communicates with the reaction silo, the outlet of the fluidized boiling box is connected with the reaction silo through the material conveying system, and a filter screen is installed on the side of the fluidized boiling box smoke outlet mesh; alkaline particles are Ca(OH) 2 , other with embodiment 1.

Embodiment 3

[0034] The basic particle in embodiment 2 is MgCO 3 , other with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com