Boiler heat exchanger welding robot workstation

A welding robot, heat exchanger technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of limited welding efficiency and quality, proficiency and operating status, unstable welding quality, and consistent welding problems such as poor sex, to achieve the effect of reducing production costs, high work efficiency, and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

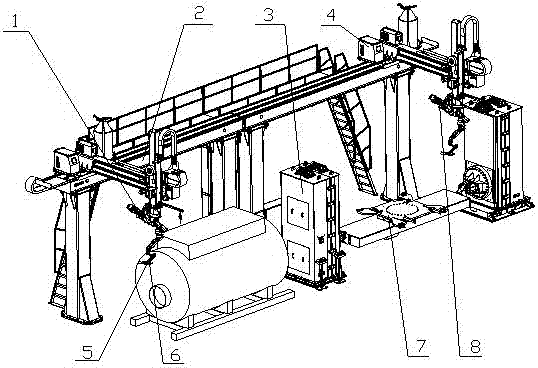

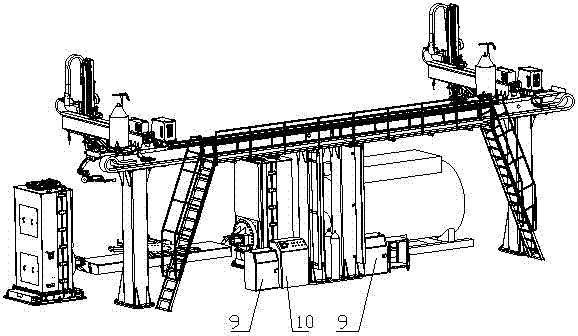

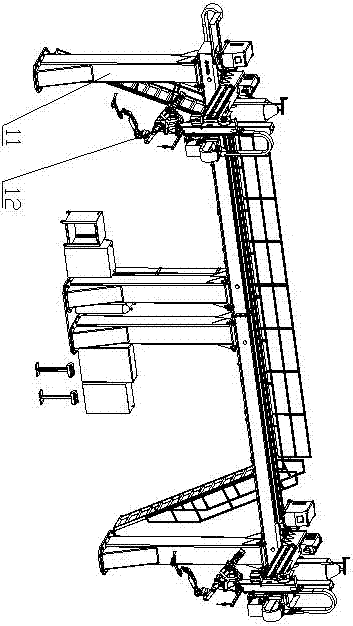

[0065] Such as Figure 1 to Figure 34 As shown, a boiler heat exchanger welding robot workstation includes a welding robot 1, a gantry 2, a liftable double-rotation positioner 3, a tooling fixture 7, a welding power source 4, a welding torch kit 5, and a laser tracking system 6. Gun cleaning station 8, robot control cabinet, general control cabinet and other electrical control systems and safety protection systems.

[0066] The welding robot workstation is divided into two stations, one station is used for the welding of the upper pot cover assembly, and the other station is used for the four welding seams of the upper pot cover assembly and the butt joint of the boiler shell. The welding of the upper pot cover assembly adopts the three-axis gantry 2 and the liftable double-rotation positioner 3, which can weld different types of upper pot cover assemblies. The welding of the upper cover and the boiler shell adopts the three-axis gantry 2 welding, and the workpiece is directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com