High-efficiency method for preparing cadmium tungstate powder

A technology of cadmium tungstate and powder, which is applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve problems such as unfavorable suction filtration impurity removal process, expansion, etc., to improve suction filtration efficiency, reduce volume, and reduce reaction temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

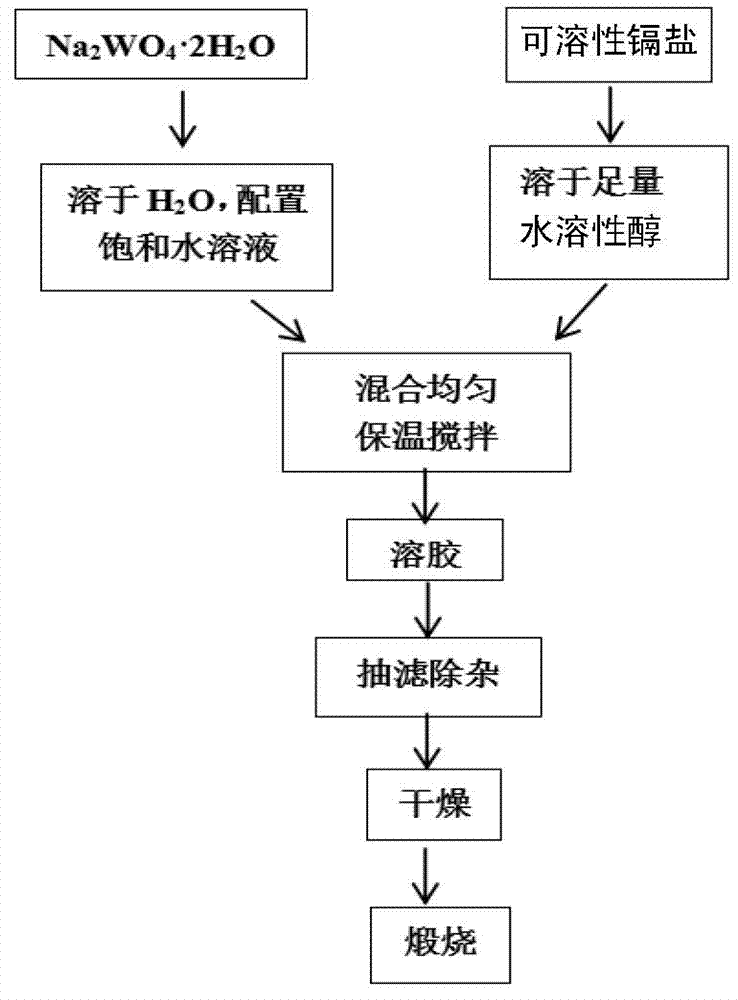

[0026] About the preparation of the precursor solution. Precursor solution of the present invention, including Na 2 WO 4 Aqueous solution and soluble cadmium salt alcohol solution. Na 2 WO 4 The aqueous solution can be made of Na 2 WO 4 2H 2 O is dissolved in pure water and prepared. Na 2 WO 4 The concentration of the aqueous solution may be 0.5-1.0 mol / L. Na 2 WO 4 If the concentration of the aqueous solution is too high, the solute is difficult to dissolve completely; Na 2 WO 4 If the concentration of the aqueous solution is too low, the preparation efficiency will be affected.

[0027] In the present invention, soluble cadmium salt is used as cadmium source, and the soluble cadmium salt alcohol solution can be obtained by dissolving soluble cadmium salt in water-soluble alcohol. Preferably, the soluble cadmium salt can be cadmium nitrate or cadmium chloride. More preferably, cadmium nitrate can be used as the soluble cadmium salt.

[0028] Preferably, the w...

Embodiment 1

[0045] 1.1 Add a certain amount of Na 2 WO 4 2H 2 O is dissolved in pure water and configured as Na with a concentration of 0.5mol / L 2 WO 4 aqueous solution;

[0046] 1.2 A certain amount of Cd(NO 3 ) 2 Dissolved in sufficient glycerol, configured as Cd(NO 3 ) 2 glycerol solution;

[0047] 1.3 Take 10mL of Na 2 WO 4 aqueous solution and 5 mL of Cd(NO 3 ) 2 Glycerol solution, mixed with each other evenly, using a magnetic constant temperature stirrer, after stirring for 1 hour at a temperature of 70 ° C, the volume of this sol is only about 1 / 2 of the cadmium tungstate sol of Comparative Example 1;

[0048] 1.4. Use the suction filtration equipment composed of Buchner funnel and circulating water vacuum pump to perform suction filtration and impurity removal operation on the sol with reduced volume. After fully drying at a temperature of 40°C, a granular solid sample was obtained;

[0049] 1.5. Put the obtained granular solid sample in a muffle furnace and calcina...

Embodiment 2

[0051] 2.1 Add a certain amount of Na 2 WO 4 2H 2 O is dissolved in pure water and configured as Na with a concentration of 0.5mol / L 2 WO 4 aqueous solution;

[0052] 2.2 A certain amount of Cd(NO 3 ) 2 Dissolved in sufficient glycerol, configured as Cd(NO 3 ) 2 glycerol solution;

[0053] 2.3 Take 10mL of Na 2 WO 4 aqueous solution and 10 mL of Cd(NO 3 ) 2 Glycerin solution, mixed with each other evenly, using a magnetic constant temperature stirrer, after stirring at a temperature of 70 ° C for 1 hour, the volume of this sol is only about 1 / 3 of the traditional method. Cadmium tungstate sol;

[0054] 2.4. Carry out suction filtration and impurity removal operation on the reduced-volume sol, and perform suction filtration for about 20 minutes each time. Place it in a constant temperature oven and fully dry it at a temperature of 40°C to obtain a granular solid. sample;

[0055] 2.5. Put the obtained granular solid sample in a muffle furnace and calcinate it at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com