Concrete nanocrystalself-compacting agent and preparationmethod thereof

A nano-crystalline, self-compacting technology, applied in the field of building materials, can solve problems such as unreasonable raw material design and building water leakage, and achieve the effects of reducing chemical incompatibility, long building life, and less water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

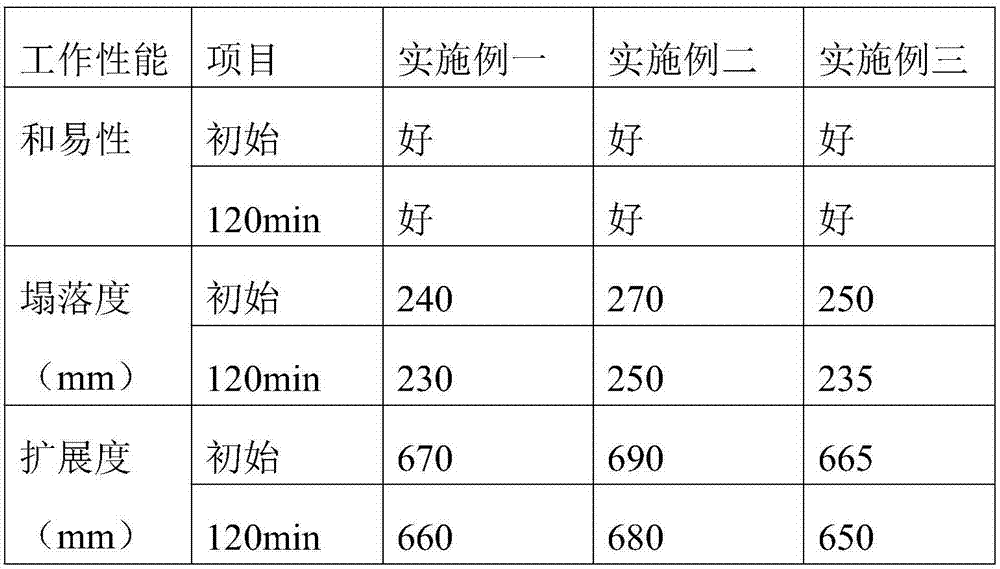

Embodiment 1

[0017] A preparation method of concrete nano crystallization self-compacting agent, comprising the following steps:

[0018] Weigh 9 parts of polyethylene glycol monomethyl ether, 5 parts of maleic anhydride, 5 parts of hydroquinone, and 52 parts of tap water, put them into a container and stir for 1 to 3 hours, let stand for 3 to 5 hours, and then pour into the container Add 7 parts of nano-alumina, 12 parts of sugarcane molasses, and 4 parts of sodium dichromate, stir evenly for 3 hours, let stand for 4 hours, adjust the pH value to 7, density 38%, filter, measure and pack the filtrate, and store it , that is.

Embodiment 2

[0020] A preparation method of concrete nano crystallization self-compacting agent, comprising the following steps:

[0021] Weigh 10 parts of polyethylene glycol monomethyl ether, 6 parts of maleic anhydride, 6 parts of hydroquinone, and 52.5 parts of tap water, put them in a container and stir for 1 to 3 hours, let stand for 3 to 5 hours, and then pour into the container Add 8 parts of nano-alumina, 13 parts of sugarcane molasses, and 4.5 parts of sodium dichromate, stir evenly for 3 hours, let stand for 4 hours, adjust the pH value to 8, density 40%, filter, measure and pack the filtrate, and store it , that is.

Embodiment 3

[0023] A preparation method of concrete nano crystallization self-compacting agent, comprising the following steps:

[0024] Weigh 11 parts of polyethylene glycol monomethyl ether, 7 parts of maleic anhydride, 7 parts of hydroquinone, and 53 parts of tap water, put them in a container and stir for 1 to 3 hours, let stand for 3 to 5 hours, and then pour into the container Add 9 parts of nano-alumina, 14 parts of sugarcane molasses, and 5 parts of sodium dichromate, stir evenly for 3 hours, let stand for 4 hours, adjust the pH value to 8, density 41%, filter, measure and pack the filtrate, and store it , that is.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com