High-purity SiC voltage-sensitive ceramic

A technology of varistor ceramics and powders, which is applied in varistors, varistor cores, etc., can solve the problems of performance impact and difficulty in ensuring the stability of electrical performance, etc., and achieve the effect of good pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

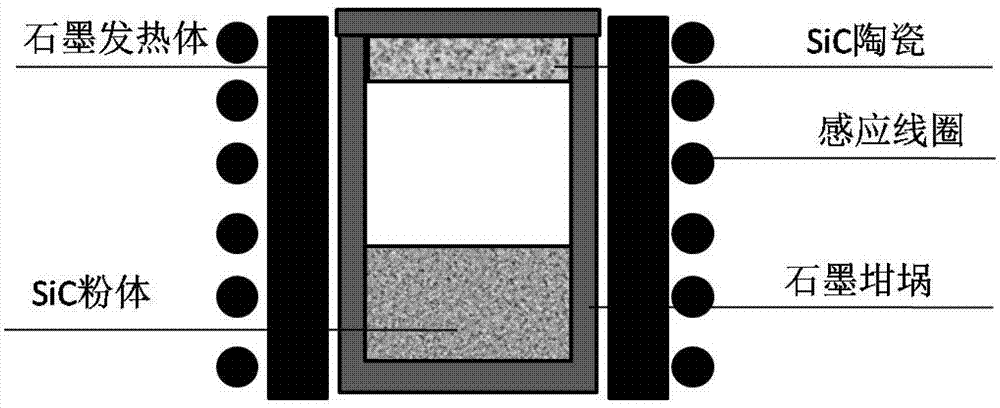

[0022] As a high-density and high-purity SiC pressure-sensitive ceramic and a preparation method thereof, the invention comprises the following steps: using high-purity SiC powder as a raw material. The raw materials are placed at the bottom of the graphite crucible of the medium frequency induction high temperature sintering furnace, and the porosity is 50%-70%. Vacuumize the furnace, heat the graphite crucible to a certain temperature of 1200°C, and remove the impurities adsorbed by the SiC powder at high temperature. Introduce high-purity Ar gas, and the air pressure is controlled within a certain range (the air pressure is 10 3 -10 5 Pa), the temperature of the furnace was raised to 2200°C, and the temperature gradient in the height direction of the crucible was controlled at 2.5°C-4.0°C / mm. The particle size of the SiC powder is 0.1-1 μm. The purity of the SiC powder is 99.9wt%. The vacuum degree≤10 -3 Pa.

[0023] The SiC ceramic density prepared by the present inv...

Embodiment 1

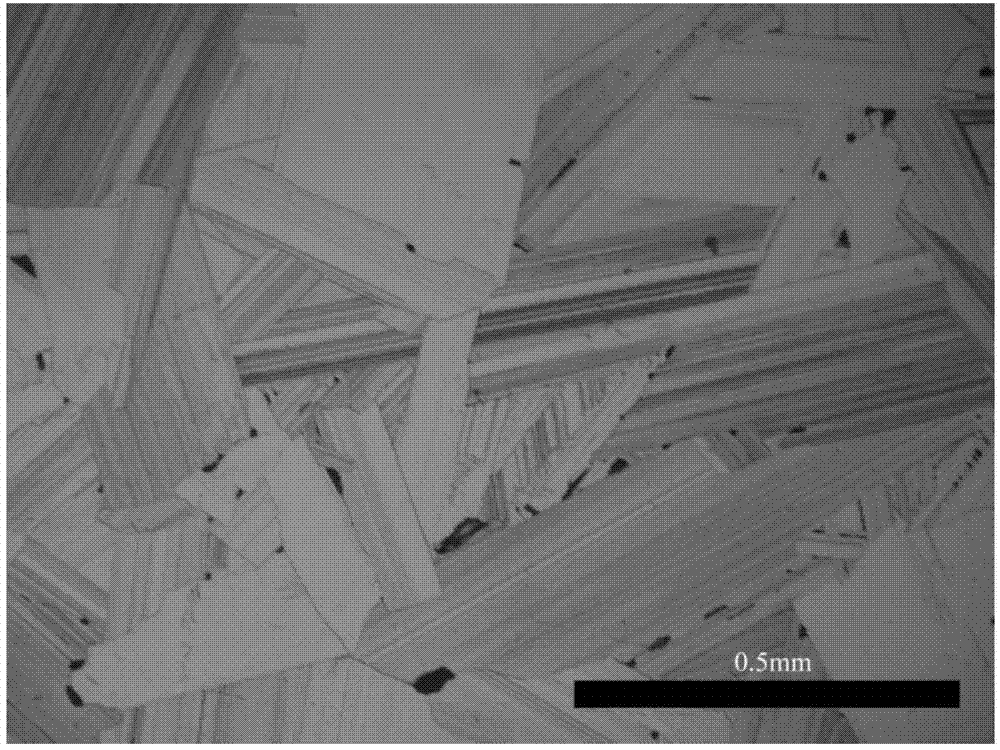

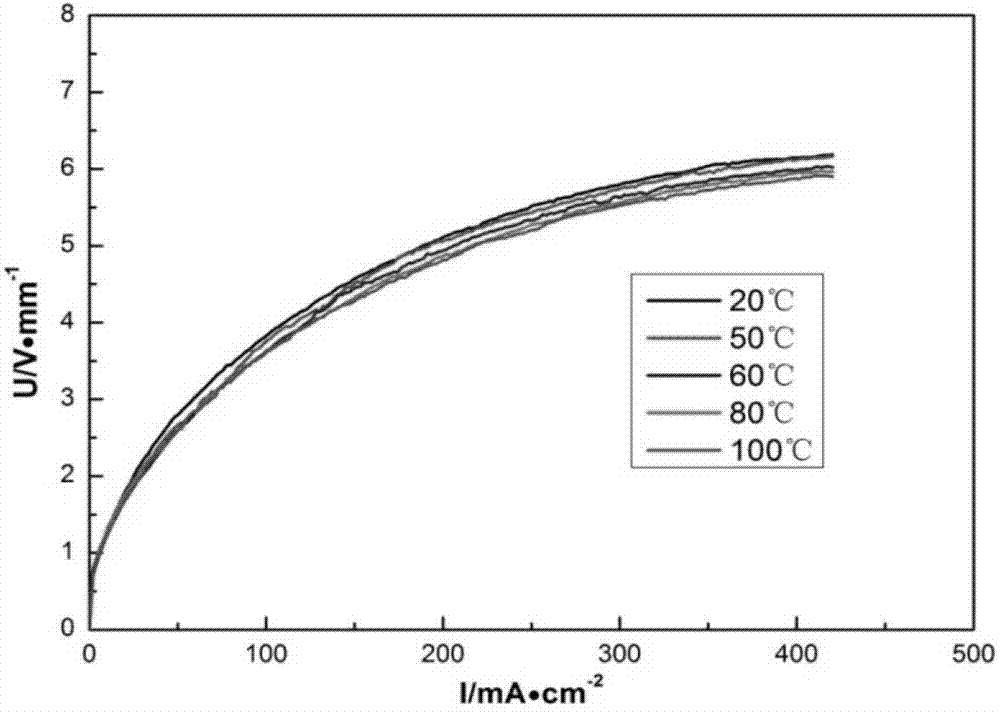

[0026] Select SiC high-purity powder with an average particle size of 0.5 microns and a purity of 99.9%. Put the SiC powder into the bottom of the graphite crucible of an intermediate frequency induction graphite furnace. The porosity of the powder is 0.6; the furnace is evacuated and the vacuum degree is controlled at 10 -3 Below Pa, heat the graphite crucible to 1200°C, and remove the impurities adsorbed by SiC powder at high temperature; feed high-purity Ar gas, and control the air pressure at 10 3 Pa, raise the temperature of the furnace to 2200°C, the temperature gradient of the furnace height is controlled at 2.5°C / mm; the holding time is 30min, and SiC ceramics are obtained, and the density of the SiC ceramics is 3.21g / cm 3 , whose microstructure is as figure 2 shown, from figure 2 The grain size of SiC ceramics can be known in the figure. Process the obtained SiC ceramics into discs with a thickness of Φ10 mm and a thickness of 2 mm, and smooth both ends, and even...

Embodiment 2

[0028] Select SiC high-purity powder with an average particle size of 0.5 microns and a purity of 99.9%. Put the SiC powder into the bottom of the graphite crucible of an intermediate frequency induction graphite furnace. The porosity of the powder is 0.6; the furnace is evacuated and the vacuum degree is controlled at 10 -3 Below Pa, heat the graphite crucible to 1200°C, and remove the impurities adsorbed by SiC powder at high temperature; feed high-purity Ar gas, and control the air pressure at 10 3 Pa, raise the temperature of the furnace to 2200°C, the temperature gradient of the furnace height is controlled at 3°C / mm; the holding time is 30min, and SiC ceramics are obtained, and the density of the SiC ceramics is 3.20g / cm 3 . Process the obtained SiC ceramics into a disc with a thickness of Φ10 mm and a thickness of 2 mm, and smooth both ends of it, and evenly coat silver paste electrodes on both ends, and then keep it in a muffle furnace for 30 minutes at 750 ° C to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Nonlinear coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com