Diamond-like carbon thin film physical film removal method and film removal equipment

A technology of diamond thin film and film stripping, applied in metal material coating process, plasma, vacuum evaporation plating and other directions, can solve the problems of time-consuming, manpower and material resources, difficult to remove effectively, unbearable cost, etc. Low cost, stable and controllable defilming process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

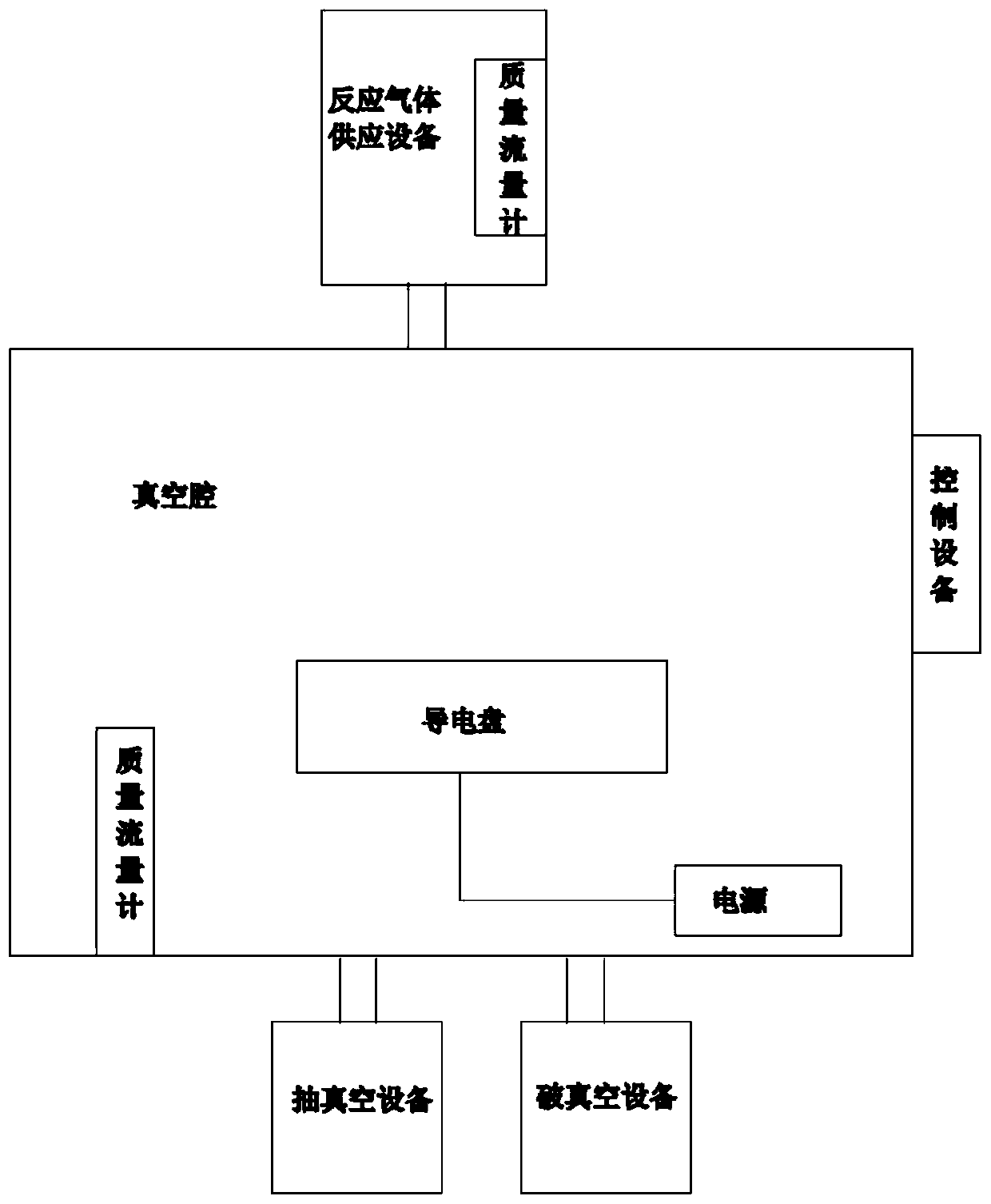

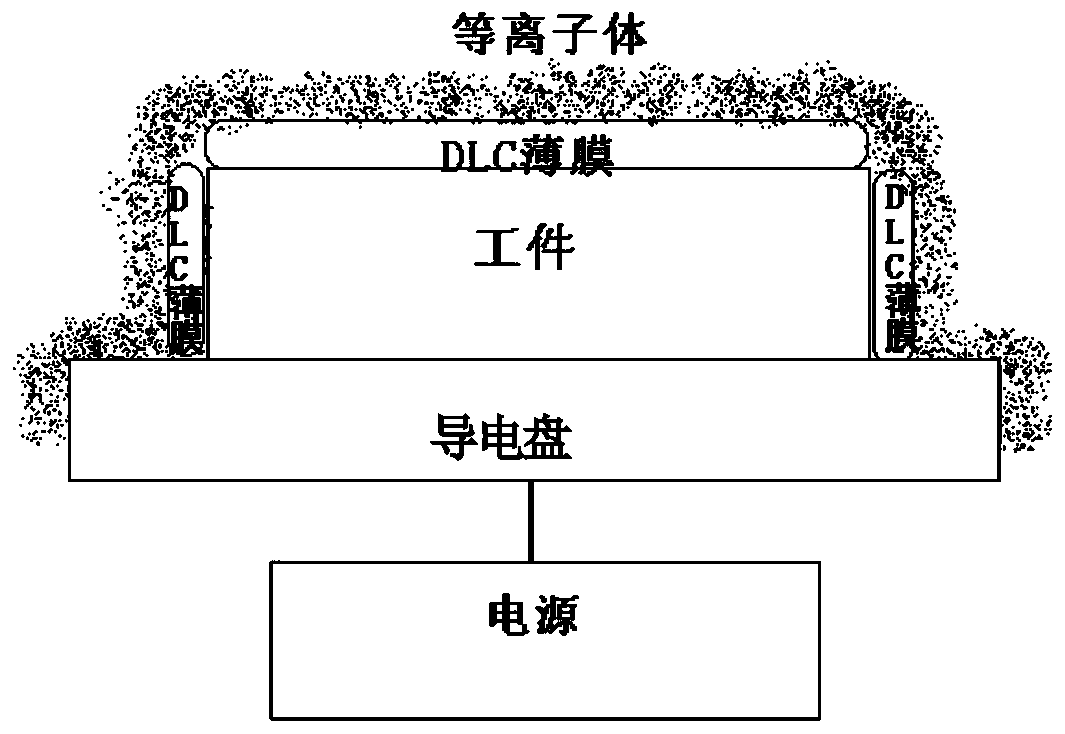

[0028] The present invention discloses a device for physical film removal of diamond-like carbon films, as shown in Figure 1, including a vacuum chamber, which is provided with an observation window, a chamber door, etc. (not shown in the figure), and the vacuum chamber The cavity is provided with a conductive plate for placing the workpiece to be filmed. The conductive plate is connected to the set power supply and has a water cooling system to reduce the high temperature caused by the heat generated by the film. Correspondingly, the vacuum chamber i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com