Etchant composition for copper-based metal layer, and method of manufacturing array substrate of display device

A technology of composition and etchant, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of poor etching profile and etching residue, and it is difficult to prevent metal oxide layer damage, and achieve excellent Etching linearity, excellent etching profile, no etching residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

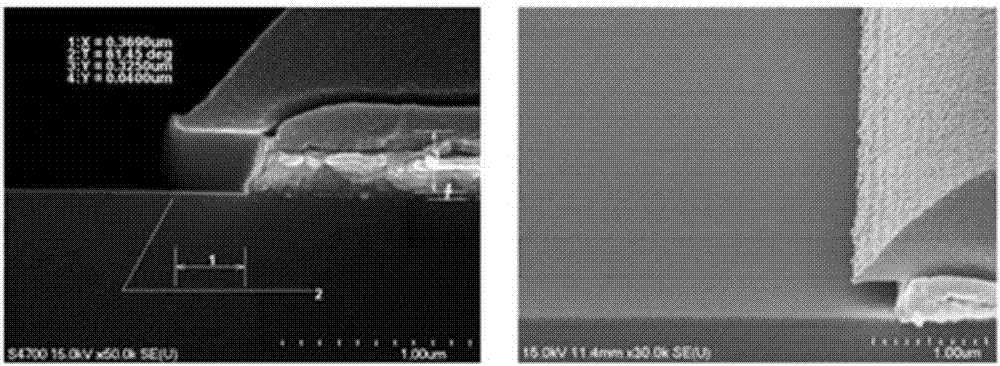

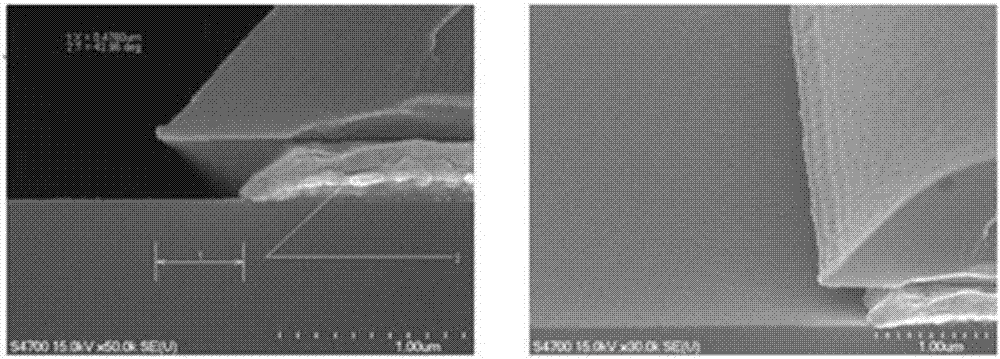

Image

Examples

preparation example Construction

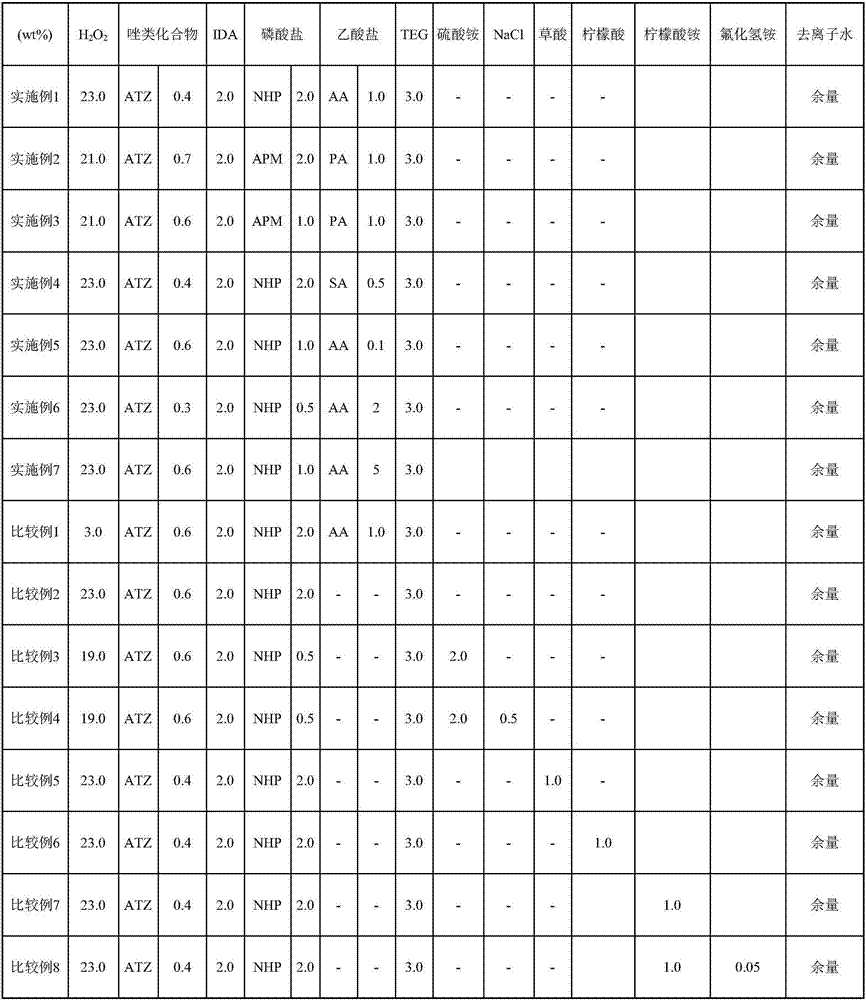

[0065] Preparation of Etchant Compositions

[0066] 6 kg of each of the etchant compositions of Examples 1 to 7 and Comparative Examples 1 to 8 were prepared using the components in the amounts shown in Table 1 below.

[0067] [Table 1]

[0068]

[0069] Note that in Table 1,

[0070] ATZ: aminotetrazole

[0071] NHP: Monosodium Phosphate

[0072] APM: Ammonium Dihydrogen Phosphate

[0073] PA: Potassium acetate

[0074] AA: Ammonium acetate

[0075] SA: Sodium acetate

[0076] TEG: triethylene glycol

[0077] IDA: iminodiacetic acid

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com