Cylindrical sintered body, cylindrical sputtering target, and method for producing the same

A technology of composition and resist, which is applied in the field of display devices, can solve problems such as difficulty in ensuring the performance of photoresist stripper, increased process loss, and high volatilization, and achieves the effect of excellent cumulative processing sheet number characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14 and comparative example 1

[0087] Examples 1-14 and Comparative Examples 1-4: Manufacture of resist stripping liquid composition

[0088] The components of the content described in following Table 1 were mixed, and the resist stripping liquid composition was manufactured.

[0089] [Table 1] (unit: weight %)

[0090]

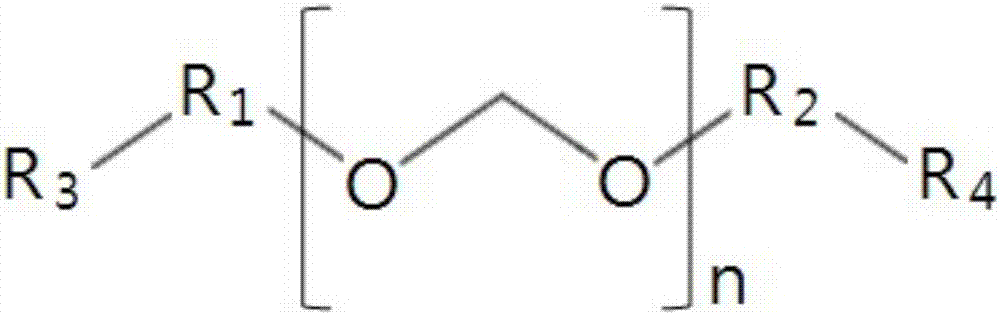

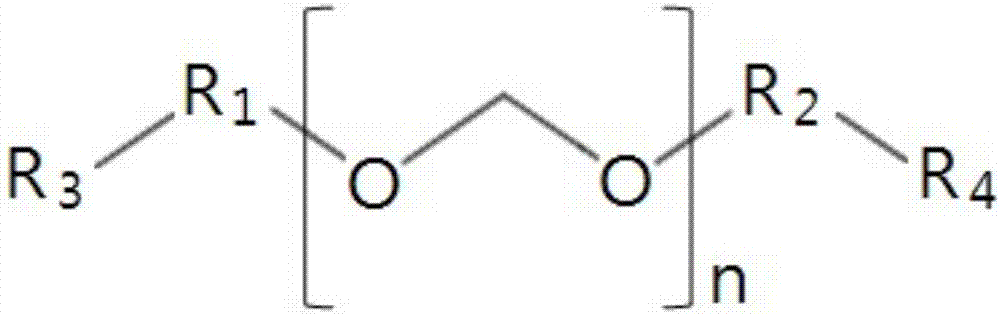

[0091] BEEM: bis(2-ethoxyethoxy)methane

[0092] BMEM: bis(2-methoxyethoxy)methane

[0093] BBEM: bis(2-butoxyethoxy)methane

[0094] TDME: Triethylene glycol dimethyl ether

[0095] MEDG: Diethylene glycol methyl ether

[0096] DGA: diglycolamine

[0097] MEA: Monoethanolamine

[0098] HEP: Hydroxyethylpiperazine

[0099] TMAH: Tetramethylammonium Hydroxide

[0100] NMP: N-Methylpyrrolidone

[0101] THFA: tetrahydrofurfuryl alcohol

[0102] EDG: Diethylene glycol monoethyl ether

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com