Fruit fermentation liquor for reducing blood glucose and preparation method of fermentation glucose

A fermentation broth, hypoglycemic technology, applied in the direction of bacteria, bifidobacteria, food science, etc. used in food preparation, can solve problems such as complex treatment, improve digestion and absorption function, increase release, and reduce blood sugar concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

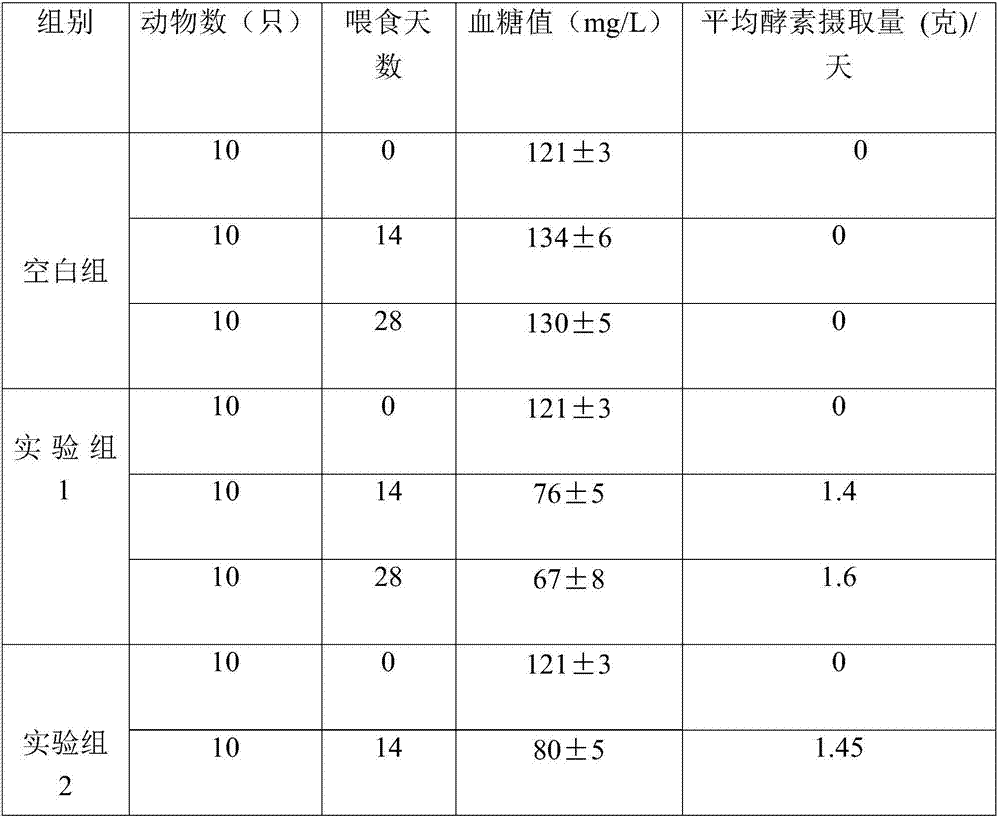

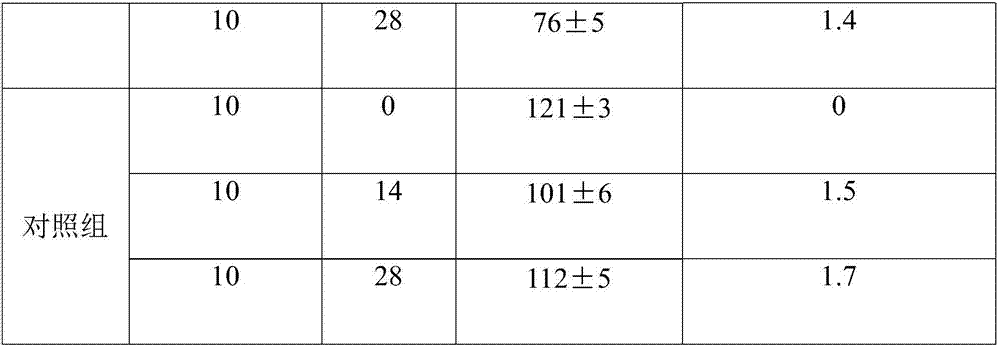

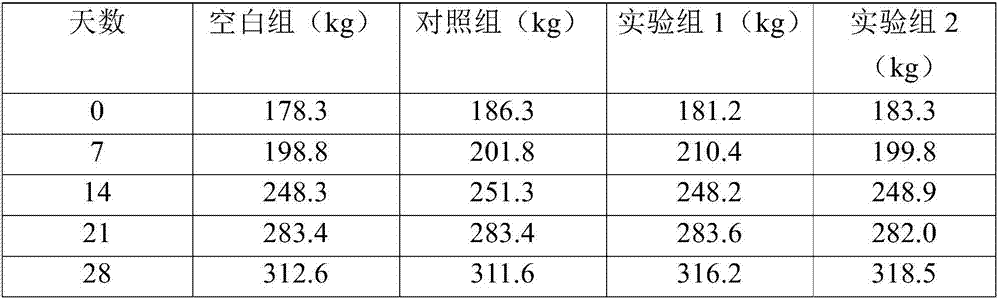

Examples

preparation example Construction

[0037] A method for preparing a hypoglycemic fruit fermentation liquid, comprising the steps of:

[0038] 1) Crush the banana leaves, guava fruit, guava leaves, Cordyceps militaris, grape seeds and grape skins, and then vibrate and extract the above raw materials at 5-10°C (oscillation rate: 150rpm / min) for 3-5h , and then freeze-dried at a temperature of -50 to -30°C and a vacuum of 2 mmHg for 40 to 50 hours, and then ground and mixed to obtain raw material powder, which is a natural plant extract.

[0039]2) Mix the raw material powder and probiotic fermentation broth, and ferment at 30-35°C for 7-10 days, when the pH value is 3-4, stop the fermentation; then add sorbitol and dietary fiber to obtain fruit fermentation broth.

[0040] A method for preparing a hypoglycemic fruit fermented liquid can also be realized through the following steps:

[0041] 1) Crush banana leaves, guava fruit, guava leaves, Cordyceps militaris, grape seeds, grape skins, dragon fruit, kiwi fruit,...

Embodiment 1

[0047] The preparation of embodiment 1 probiotic fermented liquid

[0048] Wash the pineapple, papaya, apple and mulberry separately, and in Ca(OH) pH=12 2 Soak in the solution for 2 minutes to sterilize, then drain, then mix and crush into pulp according to the ratio of mass ratio 6:1:1:2; mix the pulp and brown sugar according to the ratio of 4:1, when the temperature is 30-35 Inoculate pre-cultured 1% probiotics at 20°C, ferment for 20-30 days at 20-35°C, and end the fermentation when the pH is 3.5; then filter to obtain the probiotic fermentation broth.

Embodiment 2

[0049] The preparation of the fruit fermented liquid of embodiment 2 hypoglycemic

[0050] Fresh banana leaves, guava fruit, guava leaves, Cordyceps militaris, grape seeds and grape skins were respectively crushed, and then the above raw materials were shaken and extracted at 5-10°C (shaking speed: 150rpm / min) for 4h, and then in Freeze-dry for 48 hours at a temperature of -40°C and a vacuum of 2 mmHg, and then grind; mix the ground raw materials according to a mass ratio of 1:1:1:1:1:1 to obtain natural plant extracts; The natural plant extract and the probiotic fermentation liquid are mixed according to the mass ratio of 10:1, and fermented at 30-35°C for 7-10 days, when the pH value is 3, the fermentation is ended; then 50% Sorbitol (with reference to natural plant extracts and probiotic fermentation broth mixture, the mass percentage of sorbitol is 50%) and 50% fructo-oligosaccharides (with reference to natural plant extracts and probiotic fermentation broth mixture, low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com