Simulated ice slab and preparation method thereof

An ice board and nano-level technology, which is applied in the field of simulated ice board and its preparation, achieves the effects of high hardness, crystal clear color and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

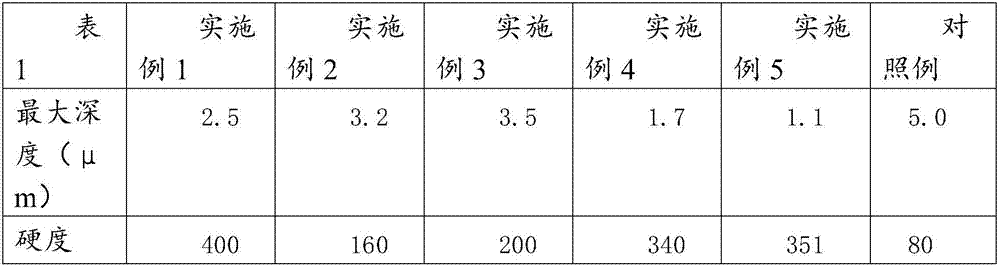

Examples

Embodiment 1

[0039] A simulated ice board, the simulated ice board comprises the following components by weight: 75 parts of polyethylene, 2 parts of polydimethylsiloxane, N,N'-di(β-naphthyl)-p-phenylenediamine 0.3 parts, 20 parts of corundum, 20 parts of dimethyl nylon acid, the particle size of the N,N'-bis(β-naphthyl)-p-phenylenediamine and corundum is nanometer size.

[0040] The polyethylene is often used as a base material for artificial ice due to its low price, low temperature resistance, stable chemical properties, odorless, non-toxic, and similar color to ice and snow; the polydimethylsiloxane has excellent wettability, and is compatible with After the polyethylene is mixed in a certain proportion, the lubricating effect of the polyethylene can be enhanced, so that its lubricity is close to that of ice cubes, and at the same time, the polydimethylsiloxane also has a brightening effect, so that the polyethylene It looks more transparent, and the polydimethylsiloxane is also an excel...

Embodiment 2

[0049] A simulated ice board, the simulated ice board comprises the following components by weight: 95 parts of polyethylene, 15 parts of polydimethylsiloxane, N,N'-di(β-naphthyl)-p-phenylenediamine 1 part, 5 parts of quartz sand, 5 parts of propylene glycol methyl ether acetate, 10 parts of pigment, the particle size of the N,N'-bis(β-naphthyl)-p-phenylenediamine and the quartz sand is nanometer size.

[0050] A method for preparing a simulated ice plate, comprising the following steps:

[0051] 1) According to the above formula, vibrate and mix the emery, N,N'-di(β-naphthyl)-p-phenylenediamine, dimethyl nylon acid, and pigment in a vibrating mixer according to the ratio, and the stirring rate is 300rpm , the stirring time is 1h, and the vibration frequency is 500Hz;

[0052] 2) Add the polydimethylsiloxane into the vibration mixer in step 1) according to the proportion, continue to vibrate and stir to obtain a mixed solution evenly, the stirring rate is 100rpm, the stirring...

Embodiment 3

[0058] A simulated ice board, the simulated ice board comprises the following components by weight: 85 parts of polyethylene, 8 parts of polydimethylsiloxane, N,N'-di(β-naphthyl)-p-phenylenediamine 0.5 parts, 10 parts of white corundum, 15 parts of dimethyl nylon acid, 3 parts of pigment, the particle size of the N,N'-bis(β-naphthyl)-p-phenylenediamine and white corundum is nanometer size.

[0059] A method for preparing a simulated ice plate, comprising the following steps:

[0060] 1) According to the above formula, vibrate and mix the carborundum, N,N'-di(β-naphthyl)-p-phenylenediamine, dimethyl nylon acid, and pigment in a vibrating mixer according to the ratio, and the stirring rate is 350rpm , the stirring time is 1.5h, and the vibration frequency is 1000Hz;

[0061] 2) Add the polydimethylsiloxane into the vibration mixer in step 1) according to the proportion, continue to vibrate and stir to obtain a mixed solution evenly, the stirring rate is 90rpm, the stirring time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Load | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com